Maintaining Efficient Production in Packaging Manufacturing: The Role of Integrated Advanced Scheduling

As a Plant Manager in a packaging manufacturing facility, you face the constant challenge of balancing production efficiency with the complexities of supply chain demands, labor management, and machine utilization. Maintaining efficient production is not just about keeping machines running but ensuring they run at optimal performance while meeting deadlines, minimizing waste, and maximizing output.

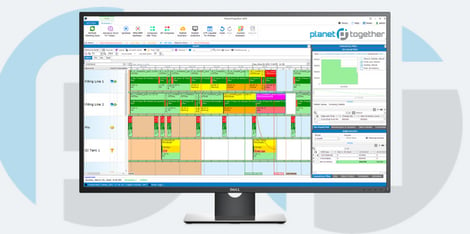

In today’s competitive market, advanced production scheduling and seamless integration with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva can significantly enhance your plant’s operational efficiency. Solutions like PlanetTogether Advanced Planning and Scheduling (APS) provide the tools to streamline production, improve resource utilization, and drive real-time decision-making.

The Challenges of Efficient Production in Packaging Manufacturing

Efficient production in packaging manufacturing requires balancing multiple moving parts. Some of the most common challenges include:

Complex Production Lines: Packaging production lines often involve intricate processes, multiple SKUs, and frequent changeovers, making it hard to maintain smooth workflows.

Unpredictable Demand: Shifts in customer demand and market conditions can disrupt production plans, leading to overproduction or missed deadlines.

Resource Constraints: Limited machine capacity, labor shortages, and raw material delays create bottlenecks that threaten efficiency.

Downtime and Waste: Unplanned machine downtime, inefficient scheduling, and scrap from production errors contribute to operational waste and higher costs.

Lack of Visibility: Without real-time visibility into production and resource availability, decision-making becomes reactive rather than proactive.

To overcome these challenges, Plant Managers must rely on data-driven tools to optimize schedules, allocate resources effectively, and ensure seamless communication across departments.

![]()

PlanetTogether APS: A Game-Changer for Production Efficiency

PlanetTogether Advanced Planning and Scheduling software is a powerful solution that addresses the unique challenges of packaging manufacturing. By integrating PlanetTogether with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, you can synchronize production planning with supply chain operations for end-to-end visibility and control.

Here’s how PlanetTogether APS enables efficient production:

1. Optimized Production Schedules

Manual scheduling can be time-consuming and prone to errors, especially in complex packaging operations. PlanetTogether APS uses advanced algorithms to optimize production schedules by:

Reducing machine idle time and bottlenecks.

Minimizing changeovers by grouping similar jobs.

Prioritizing high-value and time-sensitive orders.

Maximizing throughput with real-time data insights.

For example, by integrating PlanetTogether with SAP or Microsoft Dynamics, your scheduling system automatically pulls order data, inventory levels, and resource availability to create the most efficient production plan.

2. Real-Time Resource Allocation

PlanetTogether provides real-time visibility into machine availability, labor assignments, and raw material inventory. If a machine goes down or there’s a sudden shortage of materials, the system can automatically adjust the schedule and reroute production to minimize disruptions.

Integration with ERP systems ensures that these adjustments are communicated across the organization, keeping procurement, production, and logistics teams aligned.

3. Minimized Downtime and Waste

Downtime is one of the biggest barriers to efficient production. PlanetTogether APS helps reduce unplanned downtime by:

Proactively scheduling preventive maintenance to keep machines running smoothly.

Identifying gaps in resource utilization to balance workloads.

Minimizing overproduction and waste by aligning production schedules with real demand.

By connecting PlanetTogether with platforms like Kinaxis or Aveva, Plant Managers can access predictive maintenance insights and digital twin capabilities to forecast machine health and performance.

4. Enhanced Collaboration and Communication

A key benefit of integrating PlanetTogether with ERP systems is improved collaboration across departments. Production schedules, inventory updates, and capacity plans are synchronized, ensuring that everyone from procurement to logistics has access to the same data.

For instance, integration with Oracle ERP allows production schedules to reflect real-time inventory levels, reducing the risk of stockouts or overordering raw materials.

5. Data-Driven Decision Making

PlanetTogether provides actionable insights through visual Gantt charts, dashboards, and analytics tools. These insights help Plant Managers:

Monitor key performance indicators (KPIs) such as throughput, resource utilization, and cycle times.

Identify inefficiencies in the production process.

Make informed decisions to improve productivity and reduce costs.

Integration with ERP systems like SAP enables seamless data flow between production planning, financial management, and supply chain processes, giving Plant Managers a holistic view of plant operations.

The Power of ERP Integration: Why It Matters

Integrating PlanetTogether APS with ERP systems unlocks the full potential of production planning and scheduling. Here’s why integration is critical:

Unified Data: Real-time synchronization between ERP and APS systems ensures that production schedules align with inventory, procurement, and order management data.

Scalability: As your packaging facility grows, integrated systems can scale to handle more SKUs, complex workflows, and additional production lines.

Automation: Automating routine scheduling tasks reduces manual errors and frees up time for strategic decision-making.

End-to-End Visibility: Integrated systems provide a single source of truth for production, supply chain, and financial data, enabling better planning and coordination.

Steps to Implement PlanetTogether APS in Your Facility

Assess Your Needs: Identify the key production challenges you face and how APS can address them.

Choose the Right Integration: Determine which ERP system (SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva) you will integrate with PlanetTogether.

Collaborate with IT: Work closely with your IT team to ensure seamless integration and data flow.

Train Your Team: Provide training for production planners, schedulers, and operators to maximize the benefits of PlanetTogether APS.

Monitor and Optimize: Continuously track KPIs and make adjustments to improve scheduling efficiency.

Efficient production is the cornerstone of success in packaging manufacturing. By leveraging PlanetTogether APS and integrating it with leading ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, Plant Managers can optimize production schedules, minimize downtime, and drive operational excellence.

The result? Higher productivity, reduced costs, and the agility to meet changing customer demands in a competitive market.

Take the next step toward efficient production by exploring how PlanetTogether can integrate seamlessly with your existing systems and transform your packaging operations.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry

Topics: PlanetTogether Software, Integrating PlanetTogether, Data-Driven Decision-Making, Optimized Production Schedules, Enhanced Collaboration and Communication, Packaging Manufacturing, Real-Time Resource Allocation, Minimized Downtime and Waste

LEAVE A COMMENT