Maintaining Efficient Production in Chemical Manufacturing with PlanetTogether and ERP Integration

In chemical manufacturing, maintaining efficient production is an ongoing challenge. With fluctuating raw material costs, stringent regulatory compliance, and increasing customer demands, plant managers must adopt advanced strategies to optimize production efficiency.

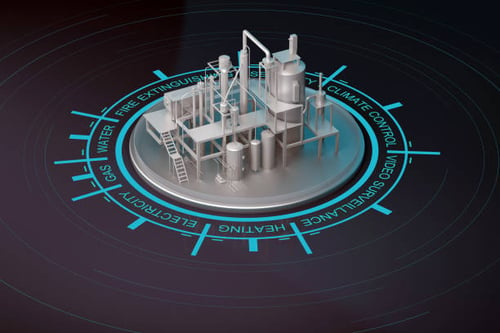

Achieving this requires a balance between operational flexibility and real-time decision-making, which can only be achieved through seamless integration between an advanced planning and scheduling (APS) solution like PlanetTogether and enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva.

The Challenges of Maintaining Efficiency in Chemical Manufacturing

The chemical manufacturing sector faces unique operational challenges that impact production efficiency, including:

Volatile Supply Chains – Chemical plants rely on a steady supply of raw materials, but disruptions in sourcing and procurement can hinder production schedules.

Complex Regulatory Compliance – Adhering to safety, environmental, and quality regulations can introduce delays if not managed properly.

Batch Processing and Sequencing – Unlike discrete manufacturing, chemical production involves complex batch processes where sequencing optimization is critical.

High Energy Consumption – Energy-intensive production requires monitoring and control to reduce costs and improve sustainability.

Equipment Reliability and Downtime – Unexpected equipment failures can disrupt entire production lines and increase maintenance costs.

The Role of PlanetTogether in Production Efficiency

PlanetTogether APS is designed to address these challenges by enhancing scheduling, resource allocation, and production visibility. It enables chemical plant managers to:

Optimize Scheduling

Ensures efficient batch production sequencing, minimizing downtime and maximizing throughput.

Increase Resource Utilization

Allocates raw materials, equipment, and labor in a way that minimizes waste and reduces idle time.

Enhance Visibility

Provides real-time insights into production processes, helping managers make data-driven decisions.

Improve On-Time Delivery

Aligns production schedules with customer demands to enhance service levels.

Reduce Inventory Costs

Supports just-in-time (JIT) manufacturing strategies to avoid excess raw material and finished goods inventory.

Leveraging ERP Integration for Seamless Operations

When PlanetTogether is integrated with ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, it bridges the gap between production planning and enterprise-wide operations. This integration offers several benefits:

Real-Time Data Synchronization

With ERP integration, real-time data exchange between production schedules and enterprise operations is enabled. For example, SAP’s ERP can provide live updates on inventory levels, procurement status, and customer orders, ensuring that PlanetTogether adjusts production schedules accordingly.

Advanced Demand Forecasting and Production Planning

Kinaxis’ supply chain planning capabilities allow chemical manufacturers to predict demand fluctuations and adjust production plans dynamically. When integrated with PlanetTogether, this results in a more responsive production environment that reduces stockouts and excess inventory.

Automated Material Requirement Planning (MRP)

Oracle ERP’s MRP functionality works seamlessly with PlanetTogether to ensure that raw materials are available at the right time. This integration minimizes production delays due to material shortages while reducing excess stockpiling.

Enhanced Regulatory Compliance and Traceability

Chemical manufacturers must maintain strict traceability of raw materials and finished products. Microsoft’s ERP solutions, when integrated with PlanetTogether, help track production batches, ensuring compliance with industry regulations such as REACH, OSHA, and EPA standards.

Optimized Resource Allocation and Equipment Utilization

Aveva’s manufacturing execution systems (MES) provide real-time performance tracking of production assets. By linking these insights with PlanetTogether, plant managers can proactively schedule maintenance, prevent equipment failures, and extend asset lifespan.

Best Practices for Integrating PlanetTogether with ERP Systems

For chemical manufacturers looking to integrate PlanetTogether with ERP solutions, consider the following best practices:

Define Clear Objectives

Establish key performance indicators (KPIs) such as reduced downtime, optimized inventory, and improved order accuracy before integration begins.

Ensure Data Accuracy and Standardization

Since APS and ERP systems rely on synchronized data, it’s crucial to standardize and validate information such as bill of materials (BOM), production orders, and resource availability.

Leverage Cloud-Based Solutions for Scalability

Using cloud-based ERP solutions like SAP S/4HANA Cloud or Oracle Cloud ERP ensures flexibility and scalability as business needs evolve.

Invest in Employee Training

Production teams, planners, and IT staff must be trained on how to leverage the APS-ERP integration for real-time decision-making and proactive problem resolution.

Continuously Monitor and Optimize

Once the integration is live, plant managers should continuously monitor system performance and adjust workflows to enhance efficiency further.

Maintaining efficient production in chemical manufacturing is an intricate process that requires advanced planning, scheduling, and enterprise-wide coordination. PlanetTogether APS, when integrated with leading ERP solutions such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, empowers plant managers to overcome industry challenges, reduce costs, and enhance operational agility. By leveraging real-time data, optimizing scheduling, and improving resource utilization, chemical manufacturers can ensure sustainable growth and competitive advantage in a rapidly evolving market.

For plant managers seeking to enhance production efficiency, the key lies in integrating smart APS solutions with robust ERP systems—a strategic investment that delivers long-term value.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Real-Time Data Synchronization, Integrating PlanetTogether, Chemical Manufacturing, Reduction in Production Lead Times, Decrease in Inventory Holding Costs, Improvement in On-time Order Fulfillment

LEAVE A COMMENT