Logistics Re-Arrangement

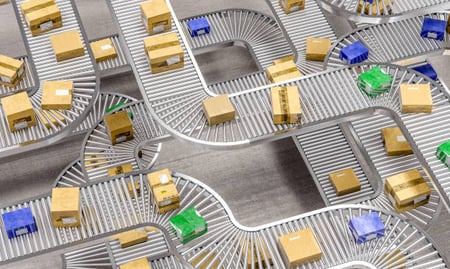

The packaging manufacturing industry faces significant challenges as the demand for faster, leaner, and more sustainable supply chains intensifies. Logistics, a critical pillar of supply chain management, requires constant reevaluation to meet evolving market dynamics. A robust logistics re-arrangement strategy can unlock efficiencies, reduce costs, and improve customer satisfaction.

For Supply Chain Managers in packaging manufacturing, leveraging advanced planning and scheduling software like PlanetTogether, integrated with enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, is essential to achieving these goals.

This blog explores the steps, benefits, and technologies involved in re-arranging logistics for optimal performance.

Why Re-Arrangement of Logistics is Crucial in Packaging Manufacturing

Increased Market Complexity

Packaging manufacturers serve diverse industries, including food and beverage, pharmaceuticals, and e-commerce, each with unique requirements. Balancing short lead times, high product variability, and fluctuating order volumes demands a flexible logistics framework.

Sustainability Pressures

Customers and regulators are pushing for greener supply chains. Re-arranging logistics to incorporate sustainable practices, such as reducing transportation distances and optimizing fleet utilization, is not just a competitive advantage but also a compliance necessity.

Global Supply Chain Volatility

Disruptions like port delays, geopolitical instability, and material shortages require agile and resilient logistics strategies. Adapting logistics processes swiftly can mitigate the impact of such disruptions.

PlanetTogether in Logistics Optimization

PlanetTogether Advanced Planning and Scheduling (APS) software is a powerful tool for re-arranging logistics in packaging manufacturing. Here’s how its integration with leading enterprise systems enhances logistics efficiency:

Seamless Data Integration

Integration with SAP, Oracle, or Microsoft Dynamics 365 ensures that logistics decisions are based on accurate, up-to-date data. Real-time synchronization across systems eliminates silos and improves cross-functional collaboration.

Intelligent Scheduling

PlanetTogether’s scheduling algorithms optimize production and logistics schedules simultaneously. For instance, aligning production output with shipment availability reduces idle time and accelerates order fulfillment.

Scenario Planning

The platform enables supply chain managers to model various logistics scenarios, such as changing delivery routes or adjusting order priorities. Integration with Kinaxis RapidResponse further enhances scenario analysis by considering supply chain-wide impacts.

Sustainability Tracking

PlanetTogether’s integration with systems like Aveva provides insights into carbon footprints and energy usage across logistics networks, helping companies meet sustainability goals.

Steps to Re-Arrange Logistics in Packaging Manufacturing

1. Assess Current Logistics Practices

Begin by mapping out the existing logistics workflows, including inbound raw material supply, internal transfers, and outbound delivery to customers. Analyze key metrics such as:

Transportation costs

Warehouse utilization

Order fulfillment times

Carbon footprint

Utilize tools like PlanetTogether APS integrated with SAP or Oracle to gain real-time visibility into logistics data and identify inefficiencies.

2. Define Strategic Objectives

Align logistics re-arrangement with broader business goals. For example:

Reducing delivery lead times to gain a competitive edge

Minimizing costs to improve margins

Enhancing sustainability to meet regulatory and market expectations

Advanced solutions like Kinaxis RapidResponse allow you to model various logistics scenarios and assess their impact on overall supply chain performance.

3. Leverage Data Analytics and AI

Data-driven insights are critical for informed decision-making. AI-enabled platforms can forecast demand, predict delays, and optimize transportation routes. Integration between PlanetTogether and Microsoft Dynamics 365 can automate the analysis of logistics data and recommend actionable improvements.

4. Optimize Inventory Placement

Strategic placement of raw materials and finished goods can significantly impact transportation efficiency. By synchronizing production schedules in PlanetTogether with inventory data from Aveva or SAP, supply chain managers can ensure that stock levels are balanced across locations to minimize unnecessary movements.

5. Reevaluate Transportation Networks

Redesign transportation routes and partnerships to maximize efficiency. Consider:

Consolidating shipments to reduce partial loads

Collaborating with logistics providers for shared transport networks

Investing in electric or alternative fuel vehicles to lower emissions

Oracle Transportation Management (OTM), integrated with PlanetTogether, can streamline route planning and monitor fleet performance in real time.

6. Implement Continuous Monitoring

Logistics re-arrangement is not a one-time effort but an ongoing process. Real-time dashboards and alerts, enabled by integrations like PlanetTogether and Kinaxis, ensure that deviations are promptly addressed, and the logistics strategy remains aligned with changing demands.

Benefits of Logistics Re-Arrangement

Cost Savings

Reduced Transportation Costs: Optimized routes and shipment consolidation lower fuel consumption and driver hours.

Lower Warehousing Expenses: Improved inventory management decreases the need for excess storage space.

Improved Customer Satisfaction

Faster and more reliable deliveries build customer loyalty and trust.

Enhanced visibility into delivery timelines provides transparency.

Sustainability Gains

Fewer vehicle miles and optimized fleets contribute to lower greenhouse gas emissions.

Energy-efficient warehouses and green packaging practices align with sustainability goals.

Increased Operational Agility

Real-time adjustments to logistics networks help manage disruptions effectively.

Integrated systems enable rapid responses to changing market demands.

In packaging manufacturing, logistics re-arrangement is a strategic imperative. By integrating cutting-edge tools like PlanetTogether with enterprise platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, Supply Chain Managers can transform logistics into a competitive advantage.

Whether it's optimizing transportation routes, improving inventory placement, or enhancing real-time decision-making, the right technologies can turn challenges into opportunities. Start your logistics re-arrangement journey today to drive efficiency, sustainability, and customer satisfaction in your supply chain.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.