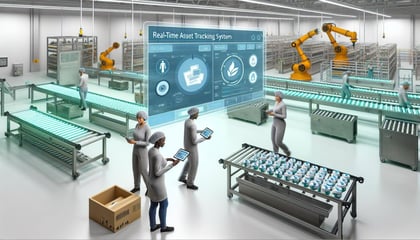

Real-Time Asset Tracking Systems

Manufacturers are continually seeking innovative solutions to streamline operations, improve productivity, and ensure regulatory compliance. Real-time asset tracking systems have emerged as a game-changer in this landscape, offering unprecedented visibility and control over assets throughout the manufacturing process.

In this blog, we look into the significance of real-time asset tracking systems in pharmaceutical manufacturing facilities, exploring their benefits, challenges, and the critical aspect of integration with enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES). Specifically, we'll discuss the integration between PlanetTogether, a leading production planning and scheduling software, and prominent ERP systems like SAP, Oracle, Microsoft, Kinaxis, Aveva, and others.

Real-Time Asset Tracking Systems

Real-time asset tracking systems utilize advanced technologies such as radio-frequency identification (RFID), global positioning systems (GPS), barcode scanning, and sensors to monitor the location, status, and condition of assets in real-time. These systems provide invaluable insights into asset utilization, maintenance needs, and process optimization opportunities.

Benefits of Real-Time Asset Tracking in Pharmaceutical Manufacturing

Enhanced Visibility: Real-time asset tracking systems offer real-time visibility into the location and movement of assets across the manufacturing facility. This visibility enables manufacturers to minimize search times, reduce asset loss or theft, and optimize asset utilization.

Improved Compliance: In highly regulated industries like pharmaceuticals, compliance with stringent regulatory requirements is non-negotiable. Real-time asset tracking systems help ensure compliance by accurately recording the movement and storage of critical assets, thereby facilitating regulatory audits and inspections.

Enhanced Efficiency: By providing real-time insights into asset availability and location, these systems enable manufacturers to optimize resource allocation, minimize downtime, and improve overall operational efficiency.

Predictive Maintenance: Real-time asset tracking systems can monitor asset health and performance parameters in real-time, enabling predictive maintenance interventions. By identifying potential issues before they escalate, manufacturers can minimize unplanned downtime and extend asset lifespan.

Challenges in Implementing Real-Time Asset Tracking Systems

While the benefits of real-time asset tracking systems are undeniable, their implementation poses certain challenges:

Integration Complexity: Integrating real-time asset tracking systems with existing ERP, SCM, and MES systems can be complex and resource-intensive. Compatibility issues, data synchronization challenges, and disparate system architectures may hinder seamless integration.

Data Security Concerns: Real-time asset tracking systems generate vast amounts of sensitive data about asset movements, locations, and performance. Ensuring data security and protecting against potential breaches or unauthorized access is critical.

Scalability: As pharmaceutical manufacturing facilities expand or evolve, the scalability of real-time asset tracking systems becomes crucial. The ability to accommodate growing volumes of assets and transactions without sacrificing performance is essential.

Integration Between PlanetTogether and ERP, SCM, and MES Systems

To maximize the value of real-time asset tracking systems, seamless integration with ERP, SCM, and MES systems is imperative. PlanetTogether, a leading provider of production planning and scheduling software, offers robust integration capabilities with a range of ERP systems, including SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, Aveva, and others.

Integration with SAP: PlanetTogether seamlessly integrates with SAP ERP, leveraging SAP's open APIs and connectors to exchange real-time data on production schedules, inventory levels, and asset requirements. This integration enables synchronized planning and execution, ensuring optimal resource utilization and on-time delivery.

Integration with Oracle: PlanetTogether's integration with Oracle ERP enables bi-directional data exchange, allowing manufacturing facilities to synchronize production plans, material requirements, and asset utilization data in real-time. This integration enhances visibility, collaboration, and decision-making across the supply chain.

Integration with Microsoft Dynamics: PlanetTogether integrates seamlessly with Microsoft Dynamics ERP, enabling pharmaceutical manufacturers to leverage real-time data insights for dynamic production planning and scheduling. This integration enhances agility, responsiveness, and operational efficiency.

Integration with Kinaxis RapidResponse: PlanetTogether's integration with Kinaxis RapidResponse enables end-to-end visibility and control over the manufacturing process. By synchronizing production plans, inventory levels, and asset tracking data, this integration facilitates proactive decision-making and continuous process improvement.

Integration with Aveva: PlanetTogether's integration with Aveva MES enhances visibility and coordination between production planning and execution. By exchanging real-time data on asset availability, work orders, and production schedules, this integration optimizes asset utilization and minimizes production disruptions.

Real-time asset tracking systems play a pivotal role in optimizing efficiency, ensuring compliance, and enhancing competitiveness in pharmaceutical manufacturing. By providing real-time visibility and control over assets, these systems enable manufacturers to streamline operations, improve resource utilization, and deliver high-quality products to market.

However, successful implementation of real-time asset tracking systems hinges on seamless integration with ERP, SCM, and MES systems. PlanetTogether's integration capabilities with leading ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, Aveva, and others facilitate data synchronization, process optimization, and informed decision-making across the manufacturing value chain.

In the ever-evolving landscape of pharmaceutical manufacturing, embracing real-time asset tracking systems and leveraging their integration capabilities is essential for staying ahead of the curve and achieving operational excellence.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the pharmaceutical industry.

LEAVE A COMMENT