Leveraging Predictive Modeling for Scheduling Optimization

In the highly regulated world of pharmaceutical manufacturing, Supply Chain Managers face unique challenges. One of the critical aspects of their role is scheduling optimization, which directly impacts production efficiency, compliance, and customer satisfaction. To address these challenges, many pharmaceutical manufacturers are turning to advanced tools and technologies, including predictive modeling, to enhance their scheduling processes.

This blog aims to provide Supply Chain Managers in pharmaceutical manufacturing facilities with valuable insights into predictive modeling for scheduling optimization. We'll also explore the integration possibilities between PlanetTogether, a renowned scheduling software, and leading ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, Aveva, and others.

The Importance of Scheduling Optimization in Pharmaceutical Manufacturing

Efficient scheduling is the backbone of pharmaceutical manufacturing. It ensures that production processes run smoothly, products are delivered on time, and resources are utilized optimally. Here's why scheduling optimization is crucial:

Compliance and Quality Assurance: Pharmaceutical manufacturing is subject to strict regulatory requirements. Accurate scheduling ensures that production complies with these regulations, resulting in high-quality products.

Cost Reduction: Efficient scheduling minimizes downtime, reduces idle resources, and lowers production costs, contributing to higher profitability.

Customer Satisfaction: Timely delivery of pharmaceutical products is vital for patient safety and satisfaction. Proper scheduling ensures that customer demands are met promptly.

Resource Utilization: Scheduling optimization helps in the effective allocation of resources, including manpower, equipment, and materials.

Predictive Modeling: A Game-Changer in Scheduling

Predictive modeling involves using historical data, algorithms, and machine learning techniques to forecast future events accurately. In the context of scheduling optimization, predictive modeling can revolutionize the way pharmaceutical manufacturing facilities operate. Here's how:

Demand Forecasting

Predictive models can analyze historical demand data, market trends, and seasonal fluctuations to predict future product demand accurately. This information allows Supply Chain Managers to adjust production schedules proactively.

Predictive Maintenance

Pharmaceutical equipment is expensive and needs regular maintenance to prevent unexpected breakdowns. Predictive maintenance models use sensor data and historical maintenance records to forecast equipment failures, enabling timely maintenance and minimizing production disruptions.

Production Capacity Optimization

Predictive modeling can analyze equipment performance, resource availability, and production constraints to maximize production capacity. This ensures that facilities operate at their highest efficiency levels.

Inventory Management

Efficient inventory management is crucial in pharmaceutical manufacturing. Predictive models can forecast inventory requirements, reducing excess stock while ensuring uninterrupted production.

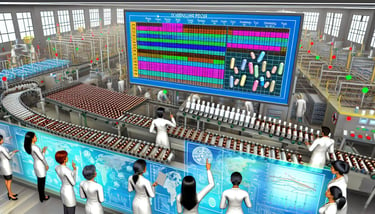

![]()

Integration with Scheduling Software: PlanetTogether

PlanetTogether is a powerful scheduling software trusted by many manufacturing industries, including pharmaceuticals. To harness the full potential of predictive modeling for scheduling optimization, integrating PlanetTogether with your existing ERP, SCM, and MES systems is essential. Here's how it can be done:

Integration with SAP

SAP is a widely used ERP system in pharmaceutical manufacturing. Integrating PlanetTogether with SAP allows real-time data exchange between scheduling and enterprise systems, streamlining production planning and execution.

Integration with Oracle

Oracle provides comprehensive SCM solutions. Integrating PlanetTogether with Oracle SCM enables efficient scheduling, order management, and inventory control.

Integration with Microsoft Dynamics

Microsoft Dynamics is a popular choice for MES and SCM in pharmaceuticals. Integrating it with PlanetTogether ensures seamless data flow and enhances scheduling accuracy.

Integration with Kinaxis

Kinaxis is known for its SCM and supply chain planning solutions. Integrating PlanetTogether with Kinaxis enables better visibility into the supply chain and improved demand forecasting.

Integration with Aveva

Aveva offers MES solutions for pharmaceutical manufacturing. Integrating it with PlanetTogether enhances production visibility and control.

Challenges and Considerations

While the integration of predictive modeling and scheduling software offers numerous benefits, there are challenges and considerations to keep in mind:

Data Quality: Accurate predictive modeling relies on high-quality data. Ensure that your data sources are reliable and up to date.

Change Management: Implementing new technologies and processes may require changes in your organization's workflow. Proper change management is crucial.

Security: Protect sensitive pharmaceutical data by implementing robust security measures when integrating software systems.

Training and Skills: Invest in training for your team to make the most of predictive modeling and scheduling software.

In the world of pharmaceutical manufacturing, Supply Chain Managers must leverage advanced tools like predictive modeling and scheduling software to stay competitive and compliant. Integrating PlanetTogether with leading ERP, SCM, and MES systems enhances scheduling accuracy, production efficiency, and resource utilization. By embracing these technologies, pharmaceutical manufacturing facilities can meet customer demands, maintain compliance, and drive profitability.

Predictive modeling for scheduling optimization is not just a trend; it's an imperative for pharmaceutical manufacturers looking to thrive in a highly competitive industry. Embrace the power of data-driven decision-making and take your scheduling processes to the next level.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Demand Forecasting, PlanetTogether Software, Enhanced Inventory Management, Integrating PlanetTogether, Data-Driven Decision-Making, Predictive Maintenance Capabilities, Production Capacity Optimization, Pharmaceutical Manufacturing

LEAVE A COMMENT