Transforming Medical Waste Management with Advanced Systems Integration

Optimize medical waste management with PlanetTogether integration and ERP systems like SAP or Oracle. Boost efficiency, sustainability, and...

Discover how Leveraging Digital Technology to Drive Sustainability contributes to Sustainability in Pharmaceutical Manufacturing.

The integration of digital technology is not just a pathway to operational efficiency—it is also becoming the cornerstone of sustainable practices. The pharmaceutical industry, with its high energy demands, water usage, and complex supply chains, is ripe for transformation. Plant managers are at the forefront of this change, tasked with not only ensuring efficient production but also reducing the environmental footprint of their operations.

One of the most effective ways to achieve sustainability goals is through the integration of advanced digital technologies, such as PlanetTogether, with enterprise systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva. These integrations enable smarter planning, enhanced resource management, and optimized operations, which are essential for reducing waste, minimizing energy consumption, and achieving long-term sustainability objectives.

In this blog, we will explore how pharmaceutical plant managers can leverage digital technology to drive sustainability, focusing on the role of integrated planning and scheduling systems like PlanetTogether, and the benefits of seamless integration with other enterprise systems.

Before looking into specific technologies and integrations, it’s essential to understand the broader context of how digital technology contributes to sustainability in pharmaceutical manufacturing. At its core, sustainability in manufacturing is about balancing operational efficiency with environmental responsibility. This can be achieved through:

With this foundation in mind, let's explore how specific digital technologies can be used to achieve these sustainability goals, starting with PlanetTogether.

![]()

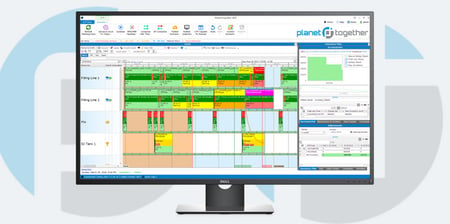

PlanetTogether is an Advanced Planning and Scheduling (APS) system that enables manufacturers to optimize production schedules, reduce lead times, and minimize waste. In the pharmaceutical industry, where precision and compliance are critical, PlanetTogether’s ability to streamline complex production processes makes it a vital tool for achieving sustainability objectives.

Here are some ways PlanetTogether contributes to sustainability:

In pharmaceutical manufacturing, wastage of raw materials due to inefficient planning can have significant environmental and financial impacts. PlanetTogether’s advanced algorithms allow plant managers to create more accurate production schedules, ensuring that materials are used optimally and reducing the likelihood of excess inventory or expired materials.

One of the key features of PlanetTogether is its ability to optimize production schedules based on energy consumption patterns. By aligning production with periods of lower energy demand or renewable energy availability, plant managers can significantly reduce the plant's overall energy consumption. This not only lowers costs but also reduces the facility's carbon footprint.

In processes that require extensive cleaning or sterilization, such as the production of sterile pharmaceuticals, water usage is a significant concern. PlanetTogether can help schedule production runs to minimize cleaning cycles, ensuring that water is used more efficiently.

Efficient use of equipment is crucial for both sustainability and profitability. By using PlanetTogether to optimize equipment schedules, plant managers can reduce the number of changeovers, leading to less downtime and more efficient use of resources.

While PlanetTogether provides robust production planning and scheduling capabilities, its true potential for driving sustainability is unlocked when it is integrated with other enterprise systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva. These integrations enable a holistic approach to sustainability by connecting planning and scheduling with broader enterprise functions, including supply chain management, inventory control, and energy management.

SAP is widely used in the pharmaceutical industry for managing various business functions, including production, procurement, and logistics. Integrating PlanetTogether with SAP allows for real-time data exchange between production planning and other business processes. For example, the integration can enable:

Synchronized Material Requirements Planning (MRP): Real-time integration ensures that production schedules are aligned with material availability, reducing the risk of overstocking or understocking materials.

Sustainability Reporting: Data from PlanetTogether can be fed into SAP’s sustainability modules, enabling plant managers to track energy consumption, emissions, and waste reduction metrics in real time.

This integration ensures that sustainability is not an afterthought but a key consideration in every production decision.

Oracle’s enterprise solutions are known for their robust analytics and reporting capabilities. When integrated with PlanetTogether, Oracle’s powerful analytics tools can provide plant managers with deeper insights into sustainability performance. Key benefits of this integration include:

Predictive Maintenance: By analyzing production data from PlanetTogether, Oracle can predict when equipment is likely to fail, reducing the need for emergency repairs and minimizing downtime. This leads to more efficient use of resources and less waste.

Energy and Resource Tracking: Oracle’s environmental reporting tools can be used to track energy and resource usage across the entire manufacturing process, helping plant managers identify areas for improvement.

Microsoft Dynamics offers flexible enterprise resource planning (ERP) solutions that can be tailored to the unique needs of pharmaceutical manufacturers. When integrated with PlanetTogether, Microsoft Dynamics provides:

End-to-End Supply Chain Visibility: Integration with PlanetTogether allows plant managers to monitor the sustainability of their entire supply chain, ensuring that suppliers adhere to environmental standards and that transportation emissions are minimized.

Sustainable Procurement: By linking production planning with procurement functions, plant managers can ensure that raw materials are sourced from sustainable suppliers and that orders are placed in line with production needs, reducing waste.

Kinaxis is a leader in supply chain planning and execution, providing real-time visibility into supply chain operations. By integrating PlanetTogether with Kinaxis, pharmaceutical manufacturers can achieve:

Demand-Driven Sustainability: Kinaxis’ real-time supply chain insights, combined with PlanetTogether’s production scheduling, ensure that production is closely aligned with demand. This reduces the risk of overproduction, which can lead to wasted resources and excess inventory.

Collaborative Sustainability Planning: Kinaxis allows for collaboration across the supply chain, enabling pharmaceutical companies to work closely with suppliers and distributors to implement sustainable practices, such as reducing transportation emissions and sourcing materials responsibly.

Aveva is known for its industrial software solutions, including energy management and sustainability tools. When integrated with PlanetTogether, Aveva can provide pharmaceutical manufacturers with:

Energy Optimization: Aveva’s energy management tools can analyze data from PlanetTogether to optimize energy usage across the entire production process. This includes identifying energy-intensive operations and finding ways to reduce their impact.

Sustainability Dashboards: Aveva’s visualization tools can create real-time dashboards that display key sustainability metrics, such as energy consumption, water usage, and carbon emissions. This enables plant managers to make data-driven decisions that support sustainability goals.

While the benefits of integrating digital technologies for sustainability are clear, plant managers may face challenges in implementing these solutions. Common obstacles include:

Data Silos: Integrating PlanetTogether with other enterprise systems requires breaking down data silos and ensuring that data flows freely between systems.

Change Management: Introducing new digital tools often requires changes in workflows and processes, which can be met with resistance from staff.

Cost Considerations: The initial investment in digital technology can be high, but the long-term benefits in terms of sustainability and efficiency often outweigh the costs.

To overcome these challenges, it is essential to work with technology partners who have experience in integrating systems and who can provide support throughout the implementation process.

Digital technology will play an increasingly important role in driving sustainability. The integration of planning and scheduling systems like PlanetTogether with enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva will enable pharmaceutical manufacturers to achieve new levels of efficiency and environmental responsibility.

For plant managers, the key to success lies in embracing these technologies and working collaboratively across departments to ensure that sustainability is embedded in every aspect of production. By leveraging digital tools, pharmaceutical manufacturers can not only meet regulatory requirements and reduce costs but also contribute to a more sustainable future for the industry as a whole.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Optimize medical waste management with PlanetTogether integration and ERP systems like SAP or Oracle. Boost efficiency, sustainability, and...

Optimize food & beverage production with PlanetTogether + ERP integration to reduce waste, cut emissions, and achieve carbon neutrality....

Discover how integrating smart waste management systems with ERP platforms transforms food and beverage manufacturing for sustainability and...

Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of today’s industry.