Data Analytics for Supply Chain Optimization

Supply Chain Managers play a pivotal role in ensuring that operations run smoothly, from raw material procurement to final product delivery in packaging manufacturing. With the advent of advanced technologies and the proliferation of data, optimizing the supply chain has become more achievable than ever before.

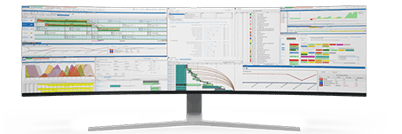

In this blog, we look into the realm of data analytics and its application in driving supply chain optimization, with a particular focus on the integration between PlanetTogether and leading ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva.

The Power of Data Analytics

Data analytics has emerged as a game-changer in the realm of supply chain management. By harnessing the power of data, organizations can gain valuable insights into various facets of their operations, enabling informed decision-making and proactive problem-solving. From demand forecasting and inventory management to production planning and logistics optimization, data analytics permeates every aspect of the supply chain, offering unprecedented opportunities for improvement and innovation.

![]()

Integration Between PlanetTogether and ERP, SCM, and MES Systems

At the heart of supply chain optimization lies seamless integration between advanced planning and scheduling (APS) systems like PlanetTogether and enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES). These integrations facilitate the flow of data across different functional areas, enabling real-time visibility, enhanced collaboration, and streamlined operations.

Integration with SAP: SAP is a leading ERP system utilized by many packaging manufacturers. By integrating PlanetTogether with SAP, Supply Chain Managers can synchronize production schedules with demand forecasts, optimize resource allocation, and automate workflows, thereby minimizing lead times and maximizing efficiency.

Integration with Oracle: Oracle's robust SCM solutions complement PlanetTogether's capabilities by providing end-to-end visibility and control over the supply chain. Integration between the two systems enables packaging manufacturers to align production schedules with procurement, inventory management, and distribution, ensuring timely delivery and customer satisfaction.

Integration with Microsoft: Microsoft offers a suite of tools, including Dynamics 365, that cater to supply chain management needs. By integrating PlanetTogether with Microsoft's ecosystem, Supply Chain Managers can leverage advanced analytics, AI-driven insights, and collaborative platforms to optimize production planning, minimize costs, and mitigate risks.

Integration with Kinaxis: Kinaxis is renowned for its cloud-based SCM platform, RapidResponse, which enables agile and responsive supply chain operations. Integration with PlanetTogether empowers packaging manufacturers to synchronize production schedules with demand fluctuations, adapt to market dynamics, and drive continuous improvement across the supply chain.

Integration with Aveva: Aveva's MES solutions enhance manufacturing efficiency by providing real-time visibility into production processes. By integrating with PlanetTogether, Supply Chain Managers can bridge the gap between planning and execution, ensuring that production schedules are aligned with shop floor realities, resource constraints, and quality standards.

Unlocking Supply Chain Optimization through Data Analytics

The integration between PlanetTogether and leading ERP, SCM, and MES systems lays the foundation for comprehensive supply chain optimization. By harnessing the wealth of data generated by these interconnected systems, Supply Chain Managers can implement data-driven strategies to:

Improve Demand Forecasting: Accurate demand forecasting is crucial for optimizing inventory levels and production schedules. By analyzing historical data, market trends, and customer insights, Supply Chain Managers can fine-tune demand forecasts, minimize stockouts, and reduce excess inventory holding costs.

Optimize Production Planning: Effective production planning requires balancing supply and demand while maximizing resource utilization and minimizing lead times. Data analytics enables Supply Chain Managers to create optimized production schedules that account for capacity constraints, material availability, and production efficiency, ensuring smooth operations and on-time deliveries.

Enhance Inventory Management: Excess inventory ties up capital and incurs carrying costs, while insufficient inventory leads to stockouts and missed sales opportunities. By leveraging data analytics, Supply Chain Managers can optimize inventory levels, identify slow-moving or obsolete stock, and implement just-in-time (JIT) inventory replenishment strategies to minimize carrying costs and maximize inventory turnover.

Streamline Logistics Operations: Efficient logistics operations are essential for minimizing transportation costs, reducing lead times, and improving customer satisfaction. Data analytics enables Supply Chain Managers to optimize route planning, consolidate shipments, and track transportation performance in real-time, thereby enhancing overall supply chain agility and responsiveness.

Mitigate Supply Chain Risks: From natural disasters and geopolitical uncertainties to supplier disruptions and quality issues, supply chain risks are ever-present. Data analytics empowers Supply Chain Managers to identify potential risks, assess their impact, and develop risk mitigation strategies, such as dual sourcing, supplier diversification, and contingency planning, to safeguard operations and ensure business continuity.

In the competitive landscape of packaging manufacturing, supply chain optimization is no longer a luxury but a necessity. By harnessing the power of data analytics and integrating advanced planning and scheduling systems like PlanetTogether with leading ERP, SCM, and MES systems, Supply Chain Managers can unlock unprecedented opportunities for efficiency, agility, and innovation.

Whether it's improving demand forecasting, optimizing production planning, enhancing inventory management, streamlining logistics operations, or mitigating supply chain risks, data analytics provides the insights and intelligence needed to stay ahead of the curve and drive sustainable growth in the packaging industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the packaging industry.

Topics: Data Analytics, PlanetTogether Software, Integrating PlanetTogether, Improve Demand Forecasting Accuracy, Optimize Production Planning, Streamlined Logistics, Packaging Manufacturing, Mitigate Supply Chain Risks, Enhance Inventory Management

LEAVE A COMMENT