Integration of AI in Medical Manufacturing Planning

With the ever-growing demand for medical supplies and devices, it's imperative to leverage cutting-edge technologies to optimize manufacturing processes and decision-making. One such technology that holds immense potential is Artificial Intelligence (AI).

In this blog, we will look into the integration of AI in medical manufacturing planning, particularly focusing on how it enhances efficiency and streamlines decision-making. Furthermore, we'll explore the benefits of integrating AI with prominent planning platforms like PlanetTogether and key enterprise resource planning (ERP) systems including SAP, Oracle, Microsoft, Kinaxis, and Aveva.

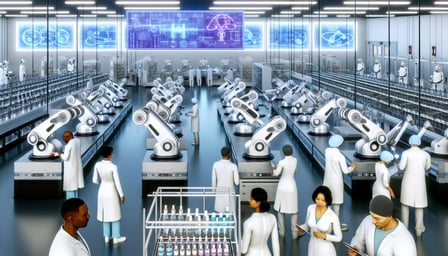

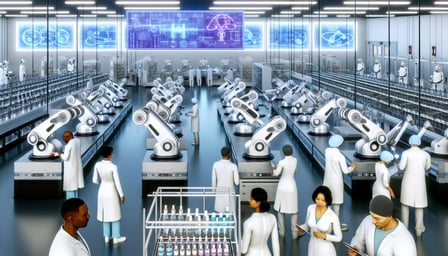

The Role of AI in Manufacturing

Artificial Intelligence, often hailed as the cornerstone of the fourth industrial revolution, offers a plethora of capabilities that can revolutionize manufacturing processes. By harnessing AI algorithms and machine learning techniques, manufacturers can gain invaluable insights from vast amounts of data, optimize production schedules, predict maintenance needs, and even enable autonomous decision-making.

Integration with Planning Platforms

PlanetTogether stands out as a leading production planning and scheduling software, renowned for its robust capabilities in optimizing complex manufacturing operations. When integrated with AI, PlanetTogether becomes even more powerful, leveraging advanced algorithms to analyze historical data, predict demand fluctuations, and dynamically adjust production schedules in real-time. This integration empowers Production Planners to make informed decisions swiftly, ensuring optimal resource utilization and on-time delivery.

Moreover, the synergy between AI and prominent ERP systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva enhances the overall efficiency of manufacturing planning. These ERP systems serve as the backbone of enterprise operations, managing various aspects such as inventory, procurement, and finance. By integrating AI capabilities into ERP systems, manufacturers can achieve seamless data flow across the organization, enabling real-time insights and predictive analytics for better decision-making.

Benefits of AI Integration in Medical Manufacturing

Optimized Production Schedules: AI-driven insights enable Production Planners to create highly optimized production schedules that align with demand forecasts, minimizing lead times and maximizing resource utilization.

Predictive Maintenance: By analyzing equipment performance data in real-time, AI can predict potential breakdowns or maintenance needs, allowing proactive maintenance to prevent costly downtime.

Demand Forecasting: Leveraging historical data and market trends, AI algorithms can forecast demand with remarkable accuracy, enabling proactive inventory management and production planning.

Resource Allocation: AI-driven recommendations facilitate efficient allocation of resources, including manpower, materials, and machinery, ensuring optimal utilization across various production lines.

Continuous Improvement: With AI's ability to learn from data and adapt to changing circumstances, manufacturing processes can undergo continuous optimization, driving productivity gains and cost savings over time.

The integration of Artificial Intelligence in medical manufacturing planning represents a paradigm shift in how Production Planners optimize processes and make decisions. By harnessing the power of AI in conjunction with advanced planning platforms like PlanetTogether and leading ERP systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, manufacturers can unlock new levels of efficiency, agility, and competitiveness.

Embracing AI-driven technologies will be essential for staying ahead of the curve and meeting the ever-growing demands of patients and healthcare providers worldwide.

With AI as a strategic ally, Production Planners can navigate complexities with confidence, driving sustainable growth and innovation in the dynamic landscape of medical manufacturing.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT