Improving Supply Chain Visibility in Medical Manufacturing

The unique demands of the industry—including stringent regulatory requirements, high product quality standards, and the urgent nature of medical device or pharmaceutical production—require seamless coordination at every level. For supply chain managers, the key to meeting these demands lies in one critical capability: visibility.

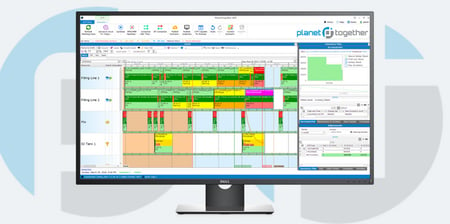

Visibility in the supply chain allows managers to monitor, adjust, and optimize operations based on real-time data, providing a competitive advantage that can reduce costs, increase productivity, and enhance service levels. In this blog, we’ll explore how integration between advanced planning and scheduling (APS) tools like PlanetTogether and enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva can unlock unparalleled visibility across the supply chain in medical manufacturing.

Visibility in Medical Manufacturing Supply Chains

Visibility in a medical manufacturing supply chain goes beyond simply tracking inventory or production schedules. It involves understanding the status of materials, demand forecasts, compliance requirements, and supplier performance in real time. For a supply chain manager, visibility provides a holistic view of operations that helps preempt potential disruptions and enhances decision-making. In medical manufacturing, where accuracy, speed, and quality are critical, these insights can make the difference between a smooth operation and a costly bottleneck.

Key benefits of visibility in a medical manufacturing supply chain include:

Proactive Risk Management: Recognize and mitigate risks, such as delayed deliveries or compliance lapses, before they impact production.

Improved Inventory Management: Optimize stock levels to ensure critical components are available when needed without overstocking.

Enhanced Agility: Quickly adapt to changes in demand or unforeseen disruptions, minimizing delays.

Regulatory Compliance: Maintain a clear record of materials, production processes, and supplier compliance for audits.

Bridging Visibility Gaps with APS and ERP Integration

While ERPs like SAP, Oracle, Microsoft, Kinaxis, and Aveva provide robust capabilities for data management and enterprise-level planning, they may lack the specialized, granular scheduling capabilities that advanced planning and scheduling systems like PlanetTogether offer. Integrating PlanetTogether with an ERP system creates a powerful framework that extends visibility into each phase of the supply chain—from raw materials to final delivery.

How PlanetTogether Complements ERP Capabilities

While ERP systems are adept at handling core data functions, they may lack the agility required for real-time scheduling changes and the complex analytics that guide efficient production. PlanetTogether fills this gap by providing dynamic scheduling, “what-if” scenario planning, and production optimization tailored for the unique demands of medical manufacturing. Integrating PlanetTogether with ERP systems gives supply chain managers a toolset to leverage the full potential of both solutions for unparalleled visibility and control.

Key Advantages of Integrating PlanetTogether with Leading ERPs

1. Real-Time Data Synchronization

By integrating PlanetTogether with SAP, Oracle, Microsoft, Kinaxis, or Aveva, data flows seamlessly between production scheduling and resource planning. This real-time synchronization ensures that everyone across the organization has access to the most current information, whether it’s inventory status, work orders, or machine availability. Real-time updates help prevent overproduction or underproduction and ensure that no unexpected shortage catches the team off guard.

2. Enhanced Forecasting and Demand Planning

ERPs excel at collecting historical sales and usage data, but they can struggle to adapt schedules to real-time shifts in demand. When PlanetTogether is integrated with an ERP, forecasting and demand planning become dynamic, allowing supply chain managers to create adaptive schedules that respond to fluctuations. Medical manufacturers often experience demand spikes for products like ventilators or diagnostic devices, and the ability to forecast and schedule production accordingly is essential for meeting demand without compromising quality.

3. Improved Supplier Collaboration and Visibility

Integrating PlanetTogether with an ERP like SAP or Kinaxis provides a shared platform where suppliers can access information relevant to them, such as material requirements, delivery schedules, and lead times. This improved visibility helps suppliers align their production and delivery with the manufacturer’s needs, leading to fewer disruptions and faster response times.

4. Optimized Inventory and Resource Allocation

Medical manufacturing requires precise control over inventory, especially when dealing with high-cost or regulated materials. Integrated APS and ERP systems allow supply chain managers to track inventory levels in real time, identify inefficiencies, and make data-driven adjustments. PlanetTogether’s advanced planning features can optimize resource allocation, ensuring that the right materials and machines are available exactly when they’re needed, avoiding unnecessary downtime or stockouts.

5. Scenario Planning for Disruption Management

In the volatile landscape of medical manufacturing, the ability to plan for contingencies is invaluable. PlanetTogether’s scenario planning capabilities, combined with the comprehensive data in ERP systems, enable supply chain managers to model the impact of disruptions (like a delayed shipment or equipment failure) and evaluate response strategies. Testing different scenarios in advance provides a solid foundation for rapid response when disruptions do occur, helping maintain service levels even in challenging situations.

6. Enhanced Compliance and Traceability

Medical manufacturers face some of the strictest regulations in the industry, requiring comprehensive traceability for all products and materials. An integrated ERP-PlanetTogether setup centralizes all compliance data, making it easy to track the origin, handling, and usage of each material across the entire supply chain. Automated tracking and reporting reduce the risk of human error and help ensure that your facility is always prepared for audits.

Real-World Applications of Enhanced Visibility in Medical Manufacturing

Let’s look at a few practical scenarios in which enhanced visibility, achieved through PlanetTogether and ERP integration, benefits medical manufacturing:

Scenario 1: Addressing Urgent Demand Spikes

A supply chain manager at a medical device company sees a sudden demand spike for respiratory equipment due to a public health crisis. With integrated visibility, they can adjust production schedules in PlanetTogether to prioritize the urgent orders. Meanwhile, the ERP system updates material requirements, ensuring that suppliers are alerted to increase raw material supply. This coordination ensures the manufacturer meets demand without delays.

Scenario 2: Compliance Audit Preparation

As part of a routine audit, a pharmaceutical company needs to provide a full record of a batch’s production process, including each material’s origin, handling, and usage. With PlanetTogether-ERP integration, the supply chain manager can easily pull comprehensive data from a single interface, including timestamps, batch numbers, and supplier information, demonstrating regulatory compliance without extensive manual documentation.

Scenario 3: Managing Supply Chain Disruptions

A supplier delays the delivery of a critical component due to transportation issues. The supply chain manager, alerted through real-time integration between PlanetTogether and the ERP system, quickly evaluates the potential impact using scenario planning. They identify an alternate supplier and adjust the production schedule to minimize downtime. Without this visibility and planning capability, the delay might have disrupted the entire production line.

Steps to Implement an Integrated APS and ERP System for Enhanced Visibility

For supply chain managers ready to harness the benefits of an integrated APS and ERP system, a strategic approach is essential. Here’s a high-level roadmap:

Define Visibility Goals: Identify key metrics that drive visibility for your supply chain, such as inventory accuracy, order lead time, and supplier performance. Clearly defining these objectives will guide the configuration and integration of PlanetTogether and your ERP system.

Integrate Core Data and Processes: Work with IT and ERP specialists to ensure seamless data flow between PlanetTogether and the ERP system. Focus on syncing critical areas like demand forecasts, inventory levels, and production schedules to eliminate information silos.

Enable Real-Time Data Access: Set up real-time data sharing between systems to provide up-to-date visibility across the supply chain. Establish automated alerts and notifications to keep the team informed of any critical updates or potential disruptions.

Train Teams for Full Utilization: Equip your supply chain, production, and procurement teams with the knowledge to leverage the integrated system effectively. Training should focus on using scenario planning, monitoring dashboards, and interpreting data insights for decision-making.

Monitor, Measure, and Improve: After implementing the integration, continuously monitor performance against your defined metrics. Use insights from the system to make data-driven adjustments, and consider expanding integration to new areas as your facility’s needs evolve.

For supply chain managers in the medical manufacturing sector, visibility is not just a competitive advantage—it’s a necessity. By integrating PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, supply chain leaders can unlock a level of visibility that goes beyond traditional ERP capabilities. This integration allows for real-time data synchronization, optimized resource allocation, proactive risk management, and enhanced compliance, all of which are crucial for meeting the demands of the medical manufacturing industry.

In an era of constant change and heightened demand, achieving supply chain visibility through integrated APS and ERP systems is one of the most powerful ways to remain agile, compliant, and resilient. By investing in this integration, supply chain managers can turn visibility into a true operational advantage, supporting both business goals and the vital needs of healthcare providers and patients around the world.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.