Improve Pharmaceutical Manufacturing with Supply Chain Digital Twins

Supply chain managers face unprecedented challenges. Balancing the need for agility, precision, and compliance while navigating global disruptions requires innovative solutions. One such breakthrough is the adoption of supply chain digital twins — a transformative technology that offers real-time, data-driven insights to optimize every facet of the supply chain.

What Are Supply Chain Digital Twins?

A digital twin is a virtual replica of a physical system. In the context of pharmaceutical manufacturing, a supply chain digital twin mirrors the entire supply chain, integrating data from production facilities, warehouses, transportation networks, and market demand. This digital model continuously updates in real-time, allowing supply chain managers to simulate scenarios, predict outcomes, and make proactive decisions.

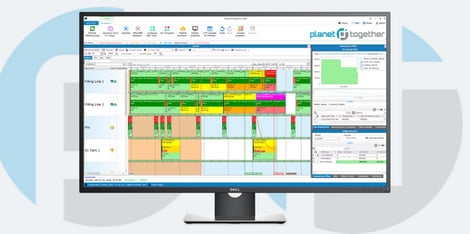

With the integration of tools like PlanetTogether APS (Advanced Planning and Scheduling) with enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, pharmaceutical manufacturers can create robust digital twins that enhance visibility and decision-making capabilities across the supply chain.

The Value Proposition of Supply Chain Digital Twins

1. Enhanced Visibility and Transparency

Digital twins break down silos by consolidating data from disparate systems into a single, unified model. This level of transparency is crucial for pharmaceutical manufacturing, where compliance and traceability are non-negotiable.

For instance, integrating PlanetTogether with SAP allows supply chain managers to visualize production schedules, inventory levels, and shipment statuses in real-time. This seamless flow of information enables quicker response to disruptions and ensures alignment with regulatory requirements.

2. Predictive Analytics and Risk Mitigation

One of the most powerful features of supply chain digital twins is their predictive capability. By leveraging historical data and machine learning algorithms, these systems can identify potential bottlenecks, forecast demand fluctuations, and assess the impact of external disruptions.

Imagine a scenario where a critical supplier faces a delay. A digital twin integrated with Kinaxis’ RapidResponse can simulate the ripple effects across the supply chain, enabling supply chain managers to identify alternative suppliers or adjust production schedules in advance.

3. Optimized Inventory Management

Pharmaceutical manufacturers often grapple with the dual challenge of avoiding stockouts and minimizing excess inventory. Digital twins provide a data-driven approach to inventory optimization.

When PlanetTogether is connected to Oracle’s ERP system, for example, it enables real-time tracking of inventory levels and demand forecasts. This integration helps supply chain managers balance just-in-time production with safety stock requirements, reducing waste and improving cash flow.

4. Accelerated Decision-Making

In an industry where time is critical, supply chain digital twins empower managers to make faster, more informed decisions. By providing a real-time view of the supply chain’s current state and simulating potential future scenarios, digital twins eliminate guesswork.

Integrating Aveva’s industrial visualization tools with PlanetTogether enhances decision-making by presenting complex data in an intuitive format. This ensures that supply chain managers can act swiftly and confidently, even in high-pressure situations.

Key Use Cases in Pharmaceutical Manufacturing

1. Streamlining New Product Launches

Launching a new pharmaceutical product involves intricate planning and coordination across the supply chain. Digital twins enable supply chain managers to simulate launch scenarios, optimizing production schedules, and distribution networks to meet market demand efficiently.

By integrating PlanetTogether with SAP, manufacturers can synchronize production planning with distribution requirements, ensuring a smooth product rollout.

2. Managing Cold Chain Logistics

Many pharmaceutical products require stringent temperature controls throughout their journey. Digital twins monitor real-time data from IoT sensors embedded in transport containers, ensuring compliance with cold chain requirements.

For example, an integration of Microsoft’s Azure IoT with PlanetTogether allows supply chain managers to track and respond to temperature deviations, safeguarding product integrity and reducing losses.

3. Navigating Regulatory Compliance

Regulatory audits demand detailed documentation of every step in the manufacturing and distribution process. Digital twins simplify compliance by maintaining a comprehensive digital record of supply chain activities.

Through Oracle’s compliance modules linked with PlanetTogether, supply chain managers can generate audit-ready reports with minimal effort, streamlining the compliance process.

Building a Digital Twin-Enabled Supply Chain

To harness the full potential of digital twins, pharmaceutical manufacturers must focus on the following:

1. Data Integration

A successful digital twin relies on seamless data integration across all supply chain nodes. This requires robust connectivity between systems like PlanetTogether and enterprise platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva.

2. Real-Time Data Collection

Real-time insights are the backbone of digital twins. Investing in IoT devices, sensors, and data streaming technologies ensures that the digital twin remains accurate and up-to-date.

3. Advanced Analytics

Implementing advanced analytics tools enhances the predictive and prescriptive capabilities of digital twins. Machine learning models can uncover hidden patterns and provide actionable recommendations to optimize supply chain performance.

4. Change Management

Adopting digital twins represents a cultural shift for many organizations. Training and change management initiatives are essential to ensure that employees can effectively leverage this technology.

The Role of PlanetTogether and Enterprise System Integration

The integration of PlanetTogether with enterprise systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva is a game-changer for supply chain digital twins. Here’s how these integrations add value:

SAP: Enhances demand planning and production scheduling by synchronizing real-time data across the supply chain.

Oracle: Optimizes inventory management and regulatory compliance through unified data models.

Microsoft Dynamics: Streamlines operations by connecting manufacturing processes with financial and supply chain workflows.

Kinaxis: Provides advanced scenario planning and risk assessment capabilities.

Aveva: Offers powerful visualization tools that bring digital twin data to life, aiding in faster decision-making.

As pharmaceutical manufacturing becomes increasingly complex, supply chain digital twins offer a vital competitive edge. By integrating PlanetTogether with robust enterprise systems, supply chain managers can unlock unparalleled visibility, agility, and efficiency.

The journey to a digital twin-enabled supply chain is not without challenges, but the rewards far outweigh the investment. For pharmaceutical manufacturers aiming to stay ahead in a dynamic market, the time to embrace supply chain digital twins is now. With the right strategy and technology partnerships, the future of pharmaceutical supply chains looks brighter than ever.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Optimized Inventory Management, Enhanced Visibility and Transparency, Pharmaceutical Manufacturing, Navigating Regulatory Compliance, Predictive Analytics and Risk Mitigation, Streamlining New Product Launches, Managing Cold Chain Logistics

LEAVE A COMMENT