Digital Manufacturing Technologies for Agile and Responsive Production

The ability to adapt quickly to changing demands while maintaining efficiency is essential in manufacturing. For Production Schedulers in chemical manufacturing facilities, the task of orchestrating production schedules amidst fluctuating market conditions and internal constraints can be daunting. However, with the integration of digital manufacturing technologies, such as PlanetTogether, with enterprise resource planning (ERP) systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, a new era of agility and responsiveness is within reach.

In this blog, we will look into the implementation of digital manufacturing technologies and explore how their integration with leading ERP systems can empower Production Schedulers to optimize production processes, streamline workflows, and ultimately enhance overall operational performance.

The Need for Agility and Responsiveness

In today's dynamic marketplace, customer demands are constantly shifting, necessitating manufacturers to be agile and responsive. For chemical manufacturers, this means being able to adjust production schedules in real-time to accommodate changing orders, market trends, and resource availability.

Traditional production scheduling methods often rely on manual processes and outdated systems, leading to inefficiencies and delays. However, by embracing digital manufacturing technologies, organizations can gain real-time visibility into their operations, enabling them to make informed decisions and respond quickly to changing conditions.

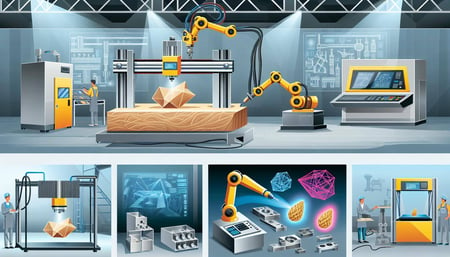

The Role of Digital Manufacturing Technologies

Digital manufacturing technologies encompass a range of tools and solutions designed to optimize production processes and enhance efficiency. From advanced planning and scheduling (APS) software like PlanetTogether to industrial Internet of Things (IIoT) devices and predictive analytics, these technologies offer a holistic approach to production management.

One of the key benefits of digital manufacturing technologies is their ability to automate and optimize production schedules. By leveraging data from ERP systems, such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, APS software can generate optimized production plans that consider various constraints, such as machine capacity, material availability, and lead times.

Integration Between PlanetTogether and Leading ERP Systems

The seamless integration between PlanetTogether and leading ERP systems provides Production Schedulers with a comprehensive solution for managing production schedules and optimizing resources. By syncing data between the APS software and the ERP system, organizations can ensure accuracy and consistency across their operations.

For example, integration with SAP enables real-time exchange of data between production scheduling and other business processes, such as inventory management and procurement. This allows Production Schedulers to make data-driven decisions based on up-to-date information, resulting in improved efficiency and reduced costs.

Similarly, integration with Oracle provides a unified platform for planning and execution, streamlining workflows and eliminating silos between departments. Production Schedulers can leverage advanced planning capabilities to optimize production schedules and respond quickly to changes in demand or supply.

Benefits of Integration for Production Schedulers

The integration between PlanetTogether and leading ERP systems offers numerous benefits for Production Schedulers, including:

Improved Visibility: By integrating production scheduling with ERP systems, Production Schedulers gain real-time visibility into production processes, enabling them to track progress, identify bottlenecks, and make proactive adjustments as needed.

Enhanced Efficiency: Automation of production scheduling tasks reduces manual effort and minimizes the risk of errors, resulting in increased efficiency and productivity.

Better Decision-Making: Access to accurate and up-to-date data allows Production Schedulers to make informed decisions based on the latest information, leading to better outcomes and improved performance.

Increased Agility: With the ability to adjust production schedules in real-time, Production Schedulers can respond quickly to changing market conditions and customer demands, ensuring timely delivery of products and services.

Best Practices for Implementation

To maximize the benefits of digital manufacturing technologies and integration with ERP systems, organizations should follow best practices for implementation, including:

Define Clear Objectives: Clearly define the goals and objectives of the implementation, including desired outcomes and key performance indicators (KPIs) for success.

Engage Stakeholders: Involve key stakeholders, including Production Schedulers, IT teams, and senior management, throughout the implementation process to ensure alignment and buy-in.

Provide Training and Support: Offer comprehensive training and ongoing support to users to ensure they are proficient in using the new technologies and tools effectively.

Monitor and Evaluate Performance: Continuously monitor and evaluate the performance of the integrated system, making adjustments as needed to optimize efficiency and effectiveness.

The implementation of digital manufacturing technologies and integration with leading ERP systems offers immense potential for chemical manufacturing facilities to achieve agility and responsiveness in production scheduling. By leveraging tools like PlanetTogether and integrating them with systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, Production Schedulers can streamline workflows, optimize resources, and adapt quickly to changing market conditions.

With careful planning, implementation, and ongoing support, organizations can unlock new levels of efficiency and performance in their production operations.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the chemical industry.