One supply chain management component that is becoming more and more appreciated is the idea of having visibility within your supply chain. Many manufacturing executives feel as if they don’t have the visibility they need into their production operations.

It is important to understand where exactly your production stands at all times. This pertains to understanding how materials are being transferred throughout production, any bottlenecks or hindrances within the manufacturing process, and if costs are not as low as they can be.

It is also important to understand the budget, resources, and any potential tasks that could be completed in a much more efficient manner. Receiving real-time data and having thorough visibility into these portions of your manufacturing process can allow you to make decisions pertaining to optimization and efficiency increase.

Although the ultimate goal is to have visibility throughout every process of the supply chain, manufacturers that do not have the required visibility may want to start by increasing visibility within their own facility. Gaining visibility across your departments will allow you to make better business decisions, optimize your production, and increase your efficiency. In this blog, we will discuss why it is important to have visibility within your manufacturing operations.

5 Reasons Why Visibility Within Your Operation is a Must

The five reasons why visibility is a must across various departments includes the following:

- Capacity Planning Improvement

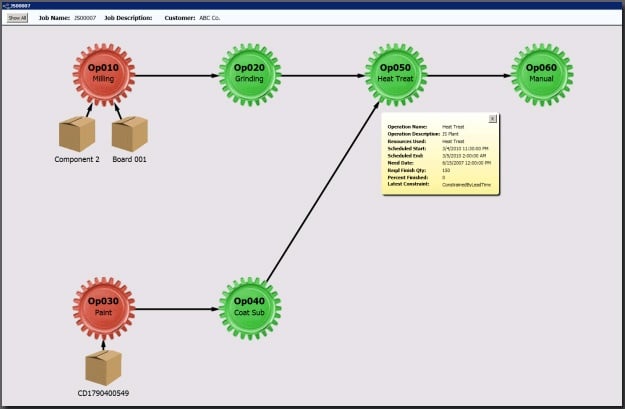

Having access to data enables you to have clear insight into future workloads. Knowing the capacity utilization of all of your departments will allow you to know whether new jobs can be inserted into the schedule. This also allows for simple modeling of utilization and requirements of resources to complete all jobs. Visibility of your current capacity gives production the ability to swiftly assess the impact of production by current/future production needs.

- Confidence Increase - Understanding what your current production status is can easily improve decision making in the future. Real-time information flow is much more efficient than analyzing data from the past, which is why real-time data can increase confidence in making decisions. Not only will visibility increase your confidence in your own production operations, it will also work to increase your customers confidence in your organization.

- Wasted Time Reduction - Wasted time is a substantial issue within many manufacturing operations, which is why visibility can offer much more thorough insight into this issue. The benefit of having a single system that is used by all departments ensures that everyone is on the same page about what capacity is available, which materials are being consumed, and what the projected finish dates are. Data visibility gives access to the data that is needed without having to rely on updates from the project staff, ultimately saving production time.

- Decision Making Enhancement - As stated in the other factors, visibility can easily aid decision making. It is impossible to make effective and reliable decisions without reliable data. Too often, managers need to make decisions without seeing the full picture, which can cause problems down the line. Having the data on hand quickly enables you to make smart and effective decisions based on the complete picture.

- Risk Identification - Identifying risks are key within a production plan. Having access to performance data allows you to identify potential risks and adjust the production plan accordingly. Visibility will also help you identify jobs and operations that do not have the required materials to start and to identify jobs that are at risk of being completed too late. Knowing this will help you be prepared for all aspects of production, keep production operations on time, and stay within your budget.

There are many benefits to having visibility across your departments. Overall, increased visibility means that your departments will be aligned towards the same goal and you will see the impact of changes in one department into the others. Visibility will highlight areas that can pose potential risks for the company as well as areas that can be improved to optimize the production process. You will be able to know the impact of how changes in one department will affect your entire schedule.

The great thing about PlanetTogether APS is that all machines can be grouped together on one screen. You know immediately how each machine impacts the others and their basic correlation to the whole schedule not only for the current week, but also for days, weeks, or months out. PlanetTogether keeps us very organized and coordinated.

JAIME OZUNA, PRODUCTION SCHEDULER, ATLANTIC COFFEE

On a larger scale, visibility into your production paired with information sharing between organizations can help you know where you stand among your competitors. Only when you can have a deep understanding of your performance can you compare it to the performance of others and develop a strategic plan to rise above the competition. Visibility is a crucial part of this.

An advanced planning and scheduling software (APS) can lead to a drastic improvement into visibility within your operation. Advanced planning and scheduling allows you to generate schedules based on resources and offers real-time data that aids management with decision making. Visibility is key within a manufacturing operation, and advanced planning and scheduling software can make it easier to accomplish.

Advanced Planning and Scheduling Software

Advanced Planning and Scheduling software has become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free demo!

Related Capacity Planning Video

APS Resources