Selecting the right production scheduling software is crucial for enhancing efficiency and profitability. With numerous options available, making an informed decision can significantly impact your business operations. This blog will guide you through the essential considerations for choosing the best production scheduling software to meet your unique needs and optimize your production processes.

Why Advanced Planning and Scheduling (APS) Software Matters: A Look at Production Scheduling Software

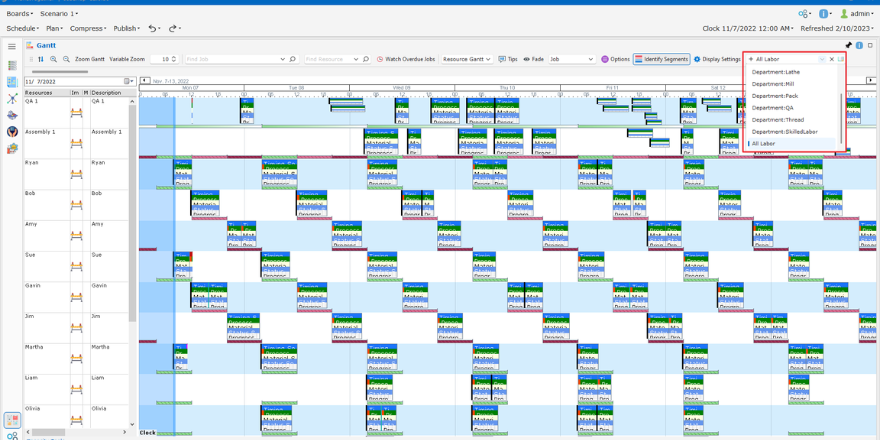

APS software is essential for manufacturers aiming to streamline operations, reduce lead times, and boost overall productivity. By automating and optimizing scheduling tasks, APS software helps businesses manage resources more effectively, minimize downtime, and ensure timely delivery of products. The right APS software can provide a competitive edge by enhancing visibility, flexibility, and responsiveness in the production process.

Key Features to Look for in APS Software

When evaluating APS software, consider the following key features that can help you achieve optimal production planning and execution:

-

1. Real-Time Data Integration

-

2. Advanced Scheduling Algorithms

-

3. Customization and Flexibility

-

4. User-Friendly Interface

-

5. Scenario Planning and Simulation

-

6. Scalability

-

7. Collaboration Tools

-

8. Analytics and Reporting

Integration with Other Key Tools / Integration Benefits

APS software's true power is realized when it integrates seamlessly with other critical tools in your manufacturing ecosystem. Here’s how APS fits with various systems:

Enterprise Resource Planning (ERP) Systems:

APS software complements ERP systems by providing detailed scheduling and planning capabilities that ERP systems typically lack. Real-time data exchange between APS and ERP ensures that scheduling decisions are based on up-to-date information on inventory levels, order status, and financial data.

Manufacturing Execution Systems (MES):

APS software integrates with MES to provide real-time feedback from the shop floor. This integration enables dynamic adjustments to schedules based on actual production conditions, leading to more accurate and efficient operations.

Customer Relationship Management (CRM) Systems:

By linking APS with CRM systems, manufacturers can better align production schedules with customer demand and order commitments. This integration ensures that production priorities are driven by real-time customer requirements and sales forecasts.

Supply Chain Management (SCM) Software:

APS software enhances SCM by providing detailed planning and scheduling insights that optimize the flow of materials and products through the supply chain. This integration improves demand forecasting, inventory management, and supplier coordination.

Project Management Software:

APS software can be integrated with project management tools to ensure that production schedules align with project timelines and resource availability. This integration helps in managing complex projects that involve multiple production stages and timelines.

Lean Manufacturing Tools:

APS software supports lean manufacturing initiatives by identifying and eliminating production inefficiencies. Tools like Kanban and value stream mapping can be integrated with APS to enhance workflow visibility and streamline operations.

Data Analytics and Business Intelligence (BI) Tools:

APS software generates valuable data that can be analyzed using BI tools to gain deeper insights into production performance. This integration helps in identifying trends, forecasting future needs, and making informed strategic decisions.

Production Scheduling Software: Making the Final Decision

Choosing the right APS software is a strategic decision that requires careful consideration. By focusing on your specific needs, evaluating key features, and understanding how APS integrates with other tools, you can select a solution that optimizes your production processes and drives your business forward.

Investing in the right Advanced Planning and Scheduling (APS) software can transform your manufacturing operations, leading to increased efficiency, reduced costs, and improved customer satisfaction. By following the guidelines outlined in this blog, you can make an informed decision and choose a tool that aligns with your business objectives. APS software, when integrated with ERP, MES, CRM, SCM, project management, lean manufacturing tools, and data analytics platforms, offers a comprehensive solution to meet your production goals.

Take control of your production with advanced production scheduling software! APS goes beyond basic scheduling, optimizing your entire process for peak efficiency.

Click here to get a demo of our production scheduling software!

Topics: Advanced Planning and Scheduling, ERP System, Business Tool, Production Scheduling Software, Integration with ERP, SCM, and MES Systems

LEAVE A COMMENT