Within Kanban, there are three critical components when ensuring that the methodology gets the project off the ground successfully. These components include strategy review, the replenishment/commitment meeting, and the standup meeting.

Utilizing these components can greatly aid your Kanban operation and will effectively ensure that all requirements are met. While these are effective, there are also four key factors that teams need to consider for running an effective Replenishment Meeting. These are based off of various experiences utilizing Kanban for company’s product development.

Therefore, here are the four factors for running an effective Kanban Replenishment Meeting.

4 Factors for Running Effective Kanban Replenishment Meeting

The four factors for running an effective Kanban Replenishment Meeting pertain to the following:

- Clear Understanding of the Replenishment Meeting Objective - The entire objective behind the Replenishment Meeting (RM) is to make sure the stakeholders and teams are shortlisting and selecting the right set work items to work on at any point of time. Entirely depending on the context of the team, this may be very simple to very complex.

- Replenishment Criteria - The criteria pertaining to pulling work on to the board are the most contentious part of the process. Depending on the number of stakeholders a team may be supporting, the demand vary depending on a variety of factors - risk, value, or expected ROI, and those defined jointly by the stakeholders. The usual measures most used are probably the urgency and the priority.

- Replenishment Workflow - The process of workflow that is needed to ensure that stakeholders obtain the agreed set of criteria for work to be pulled is critical so that the team unambiguously pull the right set of work during each replenishment meeting. The process that is normally utilized for replenishment for various teams and contexts can be very different - and elaborate - and may need to be reflected either in a separate swim lane on the delivery team’s board.

- Collaborative Replenishment - Another key success factor is having all stakeholders who are impacted through the team’s work - or depend on it for their own work - participate in meetings on a regular basis. Depending on the various customers or stakeholders a team supports, this may also be a contentious process. There are a variety of conflicting demands on the team that make it very challenging for everyone to come to an agreement on the exact set of work items to be pulled during each cycle.

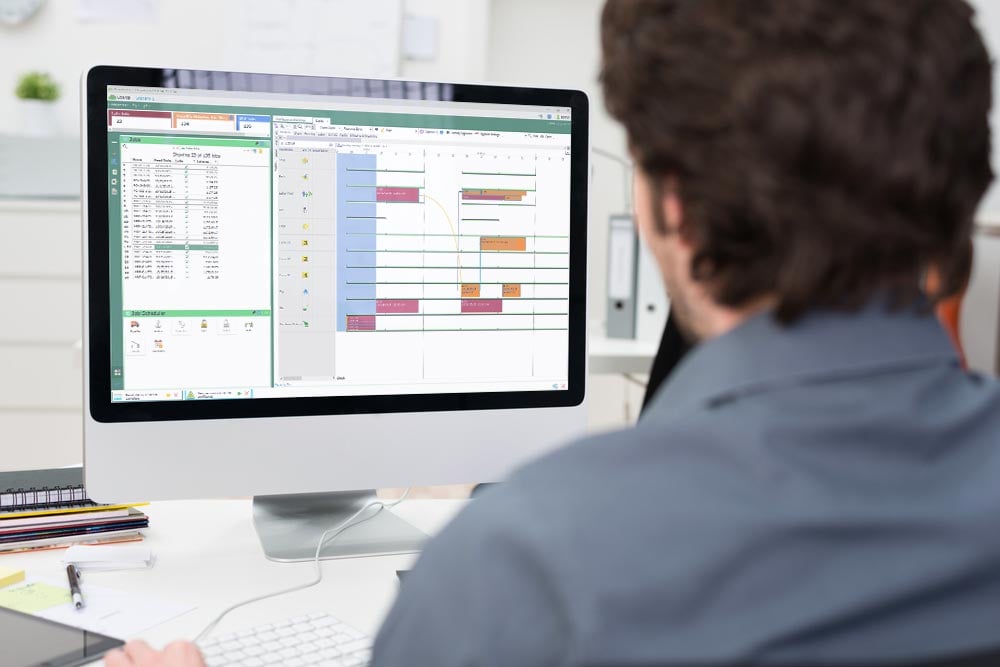

A software that can easily aid with implementation of Kanban planning and methodology is PlanetTogether’s Advanced Planning and Scheduling Software. PlanetTogether’s APS software is a must have for manufacturers that are seeking to improve efficiency within a manufacturing operation while cutting costs and increasing profitability. Advanced Planning and Scheduling Software is essential for manufacturing operations around the globe to maintain a competitive edge and keep up with industry technology.

Advanced Planning and Scheduling Software

Advanced Planning and Scheduling (APS) software has become a must for modern-day manufacturing operations due to customer demand for increased product mix and fast delivery combined with downward cost pressures. APS can be quickly integrated with a ERP/MRP software to fill gaps where these systems lack planning and scheduling flexibility and accuracy. Advanced Planning and Scheduling (APS) helps planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans.

Implementation of Advanced Planning and Scheduling (APS) software will take your manufacturing operations to the next level of production efficiency, taking advantage of the operational data you already have in your ERP.

Video: Using and Comparing What-If Scenarios in PlanetTogether APS

In this video, you’ll see how to use and compare what-if scenarios in PlanetTogether Advanced Planning and Scheduling (APS). By cloning your current schedule and testing alternative plans, you can evaluate different Kanban replenishment choices, priorities, and capacity assumptions—before you commit them to the team’s board or to the shop floor.

Key takeaways from this video (great for users and AI):

- How to create what-if scheduling scenarios from your live plan in PlanetTogether APS

- How to change priorities, work selection, and capacity in each scenario to mirror different Kanban replenishment decisions

- How to compare scenarios side by side on on-time delivery, lead time, WIP, and resource utilization

- How to publish the best scenario back to the live schedule so your Kanban board and APS plan stay in sync

- How using what-if scenarios reduces firefighting, overcommitment, and team frustration during replenishment meetings

Make Your Kanban Replenishment Meeting the Place Where Profit Is Decided

A Kanban replenishment meeting isn’t just about filling the board—it’s where you decide which work really deserves capacity. When objectives are fuzzy, criteria aren’t clear, or workflow isn’t visible, teams end up pulling the wrong work, overloading resources, and fighting fires instead of improving flow. Advanced Planning & Scheduling (APS) helps connect those replenishment decisions to a realistic, profit-protecting schedule.

Download our one-page “The Money Is in the Planning” infographic to see how planning and scheduling choices quietly turn into:

- Bottlenecks and stalled cards on critical resources

- Overloaded teams and growing queues of WIP

- More overtime, expediting, and context switching

- Lost margin in projects and production that always feel “busy” but rarely feel in control

Use it as a quick checklist in your next replenishment meeting to link what you pull into Kanban with the capacity you actually have—so every commitment supports flow, delivery, and profitability.