Enriching Cost Accounting in Pharmaceutical Manufacturing

maintaining rigorous cost control is essential not only for profitability but also for compliance with industry regulations. Purchasing managers play a critical role in this process, especially when it comes to tracking costs, negotiating with suppliers, and ensuring cost efficiency across the supply chain. One of the most effective ways to streamline these activities and achieve accurate cost accounting is through the integration of advanced production planning software, such as PlanetTogether, with established ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva. This integrated approach enables pharmaceutical manufacturers to gain real-time visibility into costs, optimize purchasing decisions, and create a more resilient and agile supply chain.

Cost Accounting in Pharmaceutical Manufacturing

Cost accounting in pharmaceutical manufacturing involves tracking and analyzing various cost components, from raw materials to labor and overhead expenses. Accurate cost data is crucial for:

Pricing and Profitability: Ensuring that products are priced to cover costs and generate a profit.

Cost Control: Identifying inefficiencies and areas where expenses can be reduced.

Regulatory Compliance: Adhering to strict industry standards and regulatory requirements.

Decision-Making: Providing actionable insights for sourcing, production, and inventory management.

Inaccurate or delayed cost data can lead to challenges such as overestimating profits, unexpected budget overruns, or inefficient resource allocation. For pharmaceutical companies, the stakes are especially high due to the high cost of raw materials and compliance requirements, which can quickly erode profit margins if not meticulously managed.

![]()

The Importance of Integration: PlanetTogether and ERP Systems

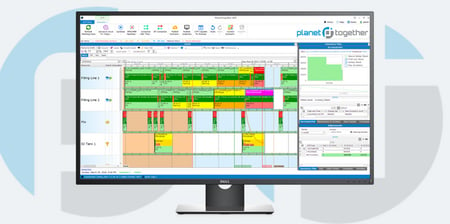

Many pharmaceutical manufacturing facilities already rely on robust ERP systems, such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, to manage various business functions, including finance, procurement, and inventory. PlanetTogether, on the other hand, specializes in production planning and scheduling, allowing companies to optimize workflows and minimize delays.

When PlanetTogether is integrated with an ERP system, the resulting data flow and insights are invaluable for effective cost accounting. Here’s how this integration benefits pharmaceutical purchasing managers:

Real-Time Data Visibility and Control

A seamless integration between PlanetTogether and an ERP system provides real-time visibility into production costs, inventory levels, and order status. For purchasing managers, this means:

Better Forecasting: By accessing up-to-date production data, purchasing managers can anticipate material requirements more accurately, reducing overstocking and stockouts.

Informed Sourcing Decisions: Real-time data from production can help identify cost variances early, enabling adjustments to sourcing decisions before they affect profitability.

Accurate Cost Allocations: With visibility into production schedules and labor usage, purchasing managers can allocate costs more accurately across different production runs, which is essential for cost accounting.

For example, if a raw material is being consumed faster than expected, purchasing managers can adjust order quantities or renegotiate prices based on actual demand, rather than outdated forecasts.

Enhanced Supplier Collaboration

The integration enables better collaboration with suppliers, a critical factor in managing costs in pharmaceutical manufacturing. Real-time data exchange between PlanetTogether and ERP systems facilitates:

Streamlined Purchase Orders: Automated order generation based on production requirements, reducing the time and effort required for manual order processing.

Flexible Scheduling: Adjusting orders in response to production schedule changes ensures that purchasing is in sync with actual demand, minimizing excess inventory.

Improved Supplier Performance: Detailed insights into supplier performance can help purchasing managers negotiate better terms and identify high-performing suppliers who offer the best balance of cost, quality, and reliability.

Integrating PlanetTogether with ERP systems also allows pharmaceutical companies to track lead times more accurately, helping purchasing managers negotiate better delivery terms based on actual supplier performance.

Optimized Inventory Management

For purchasing managers, inventory management is directly tied to cost accounting. Excess inventory ties up capital and can lead to waste, while insufficient inventory can disrupt production. Through PlanetTogether-ERP integration, purchasing managers gain the insights needed for:

Inventory Minimization: By aligning purchase orders with production schedules, the integration helps reduce inventory levels without risking stockouts, resulting in lower holding costs.

Safety Stock Optimization: Automated calculations based on real-time production data and demand fluctuations help purchasing managers maintain optimal safety stock levels, reducing the risk of obsolescence in high-cost materials.

Batch Traceability: The integration provides detailed traceability, which is essential for regulatory compliance in pharmaceutical manufacturing, reducing the risk of costly recalls.

Using PlanetTogether’s scheduling capabilities in conjunction with ERP data, purchasing managers can optimize reorder points and ensure that inventory turnover aligns with production demands, keeping inventory levels lean and costs low.

Improved Cost Allocation and Budgeting

PlanetTogether-ERP integration allows for more granular tracking of production costs, facilitating accurate cost allocations that are crucial for pharmaceutical companies where small errors in cost accounting can add up over time. For purchasing managers, this means:

Better Cost Allocation: The ability to allocate costs precisely across different batches, production lines, and product types, ensuring that each product is accurately priced and that profit margins are maintained.

Efficient Budgeting: Insights from production schedules and material requirements support accurate budgeting for materials, labor, and overhead.

Enhanced Reporting: Integrated cost data from PlanetTogether and ERP systems allows purchasing managers to generate detailed reports, providing transparency into production costs and helping to identify areas for cost reduction.

This improved cost allocation helps pharmaceutical manufacturers avoid issues like under- or overestimating product costs, which can impact pricing and profitability.

Compliance and Traceability

In an industry as regulated as pharmaceuticals, maintaining compliance is crucial, and failure to do so can lead to substantial fines and legal repercussions. Integration between PlanetTogether and ERP systems helps ensure compliance by:

Detailed Record Keeping: Integrated data systems provide comprehensive records of costs, inventory movements, and production timelines, essential for regulatory reporting.

Batch-Level Tracking: Traceability at the batch level supports compliance with standards like cGMP (current Good Manufacturing Practices) by allowing for accurate reporting of production costs and resource usage for each batch.

Regulatory Preparedness: With complete visibility over the cost and production data, purchasing managers can quickly generate reports and respond to audits or regulatory inquiries, minimizing disruptions and protecting the company’s reputation.

Through better traceability and reporting, purchasing managers can be confident that their operations are compliant, reducing the risk of costly compliance issues and potential recalls.

Key Benefits for Pharmaceutical Purchasing Managers

The integration between PlanetTogether and ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva brings numerous advantages, especially in the context of cost accounting. Purchasing managers stand to benefit from:

Enhanced Efficiency: Automated workflows reduce the manual effort required for tasks like order creation, cost tracking, and budgeting, allowing purchasing managers to focus on strategic initiatives.

Cost Savings: Real-time data access enables proactive cost control, helping purchasing managers negotiate better prices, reduce inventory holding costs, and minimize waste.

Better Decision-Making: Access to accurate, real-time data supports more informed purchasing decisions, helping to align purchasing with production needs and optimize costs.

Greater Agility: With production data directly tied to purchasing decisions, purchasing managers can quickly respond to changes in demand, supply chain disruptions, and other unexpected events.

Improved Regulatory Compliance: Comprehensive tracking and reporting capabilities ensure that purchasing activities meet regulatory standards, reducing the risk of costly non-compliance issues.

Purchasing managers are increasingly tasked with managing costs effectively while ensuring regulatory compliance in pharmaceutical manufacturing. The integration of PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva offers a powerful solution for achieving these goals. By bringing production scheduling, inventory management, and cost accounting together in a single, integrated environment, pharmaceutical companies can gain greater control over their costs, enhance efficiency, and position themselves for sustainable growth.

For purchasing managers, this integration represents an opportunity to drive substantial value, enabling more accurate cost accounting and fostering a more responsive, efficient, and compliant supply chain. As pharmaceutical companies continue to navigate economic pressures and regulatory complexities, PlanetTogether-ERP integration stands out as a key enabler of cost-effective, agile, and transparent operations in the industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Optimized Inventory Management, Enhanced Supplier Collaboration, Compliance and Traceability, Pharmaceutical Manufacturing, Real-Time Data Visibility and Control, Pricing and Profitability, Improved Cost Allocation and Budgeting

LEAVE A COMMENT