Enhancing Technological Capacity and Innovation

In an increasingly competitive landscape, production planners in medical manufacturing face ongoing pressure to boost efficiency, maintain regulatory compliance, and rapidly adapt to new market demands. To address these challenges, many medical manufacturers are turning to advanced planning systems (APS) like PlanetTogether integrated with enterprise resource planning (ERP) platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva.

This integration empowers production planners to manage technological capacity more effectively while enabling real-time innovation that aligns with the sector's high standards for precision, safety, and agility.

In this blog, we’ll explore how PlanetTogether’s integration with major ERP systems provides production planners with critical tools to manage capacity, optimize scheduling, and embrace technological innovations that drive competitive advantage in medical manufacturing.

The Challenge of Capacity Management in Medical Manufacturing

Capacity management in medical manufacturing is particularly complex due to the industry's regulatory demands, high-mix production environments, and stringent quality control measures. For production planners, balancing workloads, tracking inventory, and forecasting demand with precision are foundational aspects of their roles. Inadequate capacity management can lead to production delays, resource underutilization, and compliance risks.

Traditional planning tools struggle to keep pace with these demands. As a result, production planners need technology that provides visibility and flexibility to manage both short-term production schedules and long-term capacity planning, especially in a regulated environment where both quality and efficiency are vital.

![]()

PlanetTogether: A Foundation for Agile and Adaptive Planning

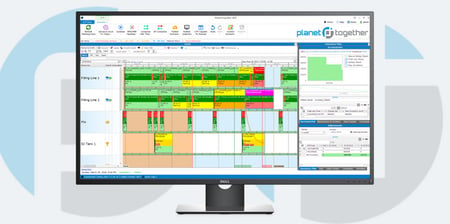

PlanetTogether's APS is designed to enhance production scheduling and resource allocation, making it a valuable asset for production planners in medical manufacturing. The software’s flexibility allows for customization to meet specific requirements, providing both a detailed view of ongoing operations and the ability to adjust to unforeseen changes in demand or resource availability.

Key features of PlanetTogether include:

Real-time scheduling: Production schedules can be updated instantly in response to new orders, equipment downtime, or workforce availability, enabling planners to adapt quickly to changes.

Resource optimization: By leveraging advanced algorithms, PlanetTogether ensures that resources—be they machines, materials, or personnel—are optimally allocated, reducing waste and maximizing productivity.

Scenario planning: PlanetTogether allows planners to simulate different production scenarios, helping them to identify the most efficient and compliant path forward.

The true potential of PlanetTogether is unlocked when it’s integrated with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, which can synchronize data across the entire organization and streamline operations from raw materials to finished products.

Leveraging ERP Integration for Seamless Data Flow and Enhanced Decision-Making

An integrated ERP-APS ecosystem is transformative for production planners in medical manufacturing, enabling them to make data-driven decisions with real-time insights. Here’s how PlanetTogether integrates with various ERP systems to enhance capacity management and innovation:

SAP Integration

For medical manufacturers using SAP, PlanetTogether integrates directly with SAP’s powerful analytics and data management tools. This integration:

Improves forecasting accuracy by leveraging SAP’s robust analytics with PlanetTogether’s scenario planning to predict capacity needs based on historical and real-time data.

Enhances material requirements planning (MRP): As SAP and PlanetTogether work together, production planners gain insights into material usage patterns, helping reduce waste and avoid stockouts.

Optimizes compliance management: SAP’s comprehensive compliance tracking aligns well with PlanetTogether’s scheduling, ensuring that production processes adhere to industry standards without sacrificing efficiency.

Oracle Integration

Oracle’s ERP suite provides deep data management capabilities that, when paired with PlanetTogether, empower production planners with enriched operational insights. Key benefits include:

Streamlined production workflows: PlanetTogether’s real-time scheduling data helps planners make adjustments based on Oracle’s extensive inventory and financial reporting, optimizing resource allocation across departments.

Improved demand planning: By combining Oracle’s predictive demand forecasting with PlanetTogether’s scheduling, production planners can anticipate demand shifts, making proactive adjustments to capacity plans.

Compliance and traceability: Oracle’s traceability features track every step in the production chain, allowing planners to uphold regulatory compliance seamlessly through synchronized data.

Microsoft Dynamics Integration

Microsoft Dynamics ERP offers a flexible foundation for digital transformation in manufacturing, and when integrated with PlanetTogether, production planners gain a collaborative environment to drive innovation. This integration provides:

Enhanced cross-functional collaboration: Microsoft Dynamics' collaborative tools enable data sharing across teams, ensuring that planners, quality managers, and supply chain coordinators have access to the latest production information.

Real-time production monitoring: With both systems in sync, production planners can track work-in-progress and quickly respond to issues, reducing delays and increasing throughput.

Predictive maintenance: Microsoft Dynamics’ IoT and machine learning capabilities, combined with PlanetTogether, can help predict equipment failures and schedule preventative maintenance to reduce downtime.

Kinaxis Integration

For organizations focused on rapid response and agility, Kinaxis and PlanetTogether offer powerful solutions for end-to-end supply chain and production planning:

Demand-driven capacity planning: Kinaxis’ strong demand sensing capabilities allow production planners to adjust capacity based on current demand fluctuations, keeping the production line flexible and responsive.

Reduced lead times: Kinaxis’ visibility across the supply chain, coupled with PlanetTogether’s scheduling, can minimize lead times by synchronizing production activities with supplier availability.

Risk management: This integration enables planners to identify supply risks and adjust schedules or capacity to mitigate disruptions, ensuring a steady production flow.

Aveva Integration

Aveva’s digital solutions are ideal for environments where predictive analytics and asset management are paramount. Integration with PlanetTogether allows for:

Advanced analytics integration: Aveva’s analytics tools provide insights into equipment performance, which can be fed into PlanetTogether’s scheduling engine for optimized uptime.

Asset-centric scheduling: Aveva’s focus on asset performance management, when linked with PlanetTogether, allows production planners to schedule production around asset availability, ensuring that equipment capacity is fully leveraged.

Regulatory alignment: By integrating compliance data from Aveva with PlanetTogether’s scheduling, production planners can align production schedules with regulatory demands efficiently.

Realizing Innovation in Production Planning with Integrated Solutions

PlanetTogether and ERP integration go beyond capacity management to foster a culture of continuous innovation. This is particularly relevant in medical manufacturing, where production planners are increasingly expected to contribute to operational improvements and strategic initiatives. Here’s how an integrated APS-ERP setup supports innovation:

Data-driven decision-making: With access to synchronized data across the organization, production planners can analyze trends, track key performance indicators (KPIs), and make decisions based on a full picture of the production landscape.

Enhanced responsiveness to market changes: The healthcare sector is known for rapid shifts in demand, especially during public health crises. Integration allows planners to adjust capacity and scheduling dynamically, maintaining production continuity and meeting market demands efficiently.

Sustainability and waste reduction: With integrated insights into resource usage and inventory levels, production planners can identify and eliminate inefficiencies, reducing waste and promoting sustainability initiatives.

Building a Resilient Production Environment with PlanetTogether and ERP Integration

In a sector that demands both agility and stability, integrated planning solutions provide medical manufacturers with the resilience needed to adapt to external pressures and internal challenges. By connecting PlanetTogether with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, production planners can:

Adapt to regulatory changes seamlessly: As regulations evolve, integrated systems allow for quick updates and compliance adjustments across production processes.

Prepare for future growth: Integration ensures that production planning scales alongside organizational growth, facilitating the introduction of new product lines and increased production volumes.

Maintain operational efficiency during disruptions: During supply chain disruptions or equipment failures, an integrated system provides the visibility needed to reschedule resources effectively and minimize downtime.

Technological capacity and innovation are the cornerstones of effective production planning in medical manufacturing. By leveraging the powerful combination of PlanetTogether’s advanced planning capabilities and the comprehensive data insights offered by ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, production planners can drive efficiency, ensure compliance, and cultivate a culture of innovation.

This integration enables them to manage complex production schedules with greater precision and agility, ultimately positioning their organizations to thrive in a competitive, fast-paced industry.

For medical manufacturing facilities aiming to enhance their operational resilience and align with industry advancements, the strategic adoption of integrated planning tools is a vital step forward. PlanetTogether and ERP integration empower production planners to not only meet today’s demands but also anticipate and shape the future of medical manufacturing.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Resource Optimization, PlanetTogether Software, Integrating PlanetTogether, Medical Manufacturing, Improves Forecasting Accuracy, Advanced Scenario Planning, Streamlined Production Workflows, Enhanced Cross-functional Collaboration, Demand-driven Capacity Planning, Advanced Analytics Integration

LEAVE A COMMENT