Enhancing Resource Availability and Managing Constraints

In the complex environment of pharmaceutical manufacturing, production schedulers are constantly faced with challenges in balancing resource availability, constraints, and dependencies. Every component—from skilled personnel and critical equipment to specialized materials—requires precise orchestration to meet stringent regulatory standards and market demands.

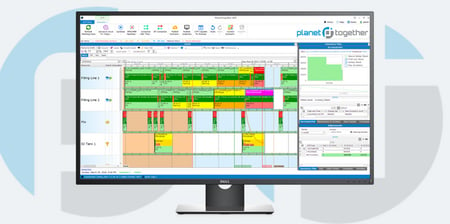

At the core of these operations, advanced scheduling software like PlanetTogether, integrated with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, can offer a powerful solution to these challenges. By enabling real-time visibility, automating constraint management, and optimizing scheduling, integrated systems can empower schedulers to operate with heightened efficiency and agility.

This blog looks into how the integration of PlanetTogether with leading ERP systems supports production schedulers in addressing the multifaceted challenges of resource availability, constraints, and dependencies in pharmaceutical manufacturing.

The Complexity of Resource Availability in Pharmaceutical Manufacturing

In pharmaceutical production, resource availability spans a broad spectrum, including labor, machinery, materials, and utilities. Each category has unique availability dynamics:

Labor Resources: Scheduling personnel with specialized skills or certifications is crucial for tasks like sterile compounding or quality checks.

Machinery and Equipment: Equipment availability is influenced by maintenance schedules, operational cycles, and calibration needs, especially in highly regulated environments.

Materials and Ingredients: Material lead times and availability can vary widely, especially for active pharmaceutical ingredients (APIs) with limited suppliers or those sourced globally.

Utilities: Access to cleanroom environments, stable power, and adequate water supply are additional resources that must be managed closely.

Without integrated systems, tracking and updating resource availability in real-time can be labor-intensive and prone to errors. Here, PlanetTogether’s integration with ERP solutions like SAP, Oracle, and Microsoft Dynamics serves as a powerful tool. It pulls data from these systems to provide a centralized view of resource availability, updating automatically based on live data inputs from across the operation.

This capability allows production schedulers to make informed decisions about when and how resources can be allocated, reducing downtime and maximizing productivity.

![]()

Managing Constraints with Integrated Scheduling and ERP Systems

Constraints are a given in pharmaceutical manufacturing. Whether related to regulatory standards, equipment capacities, or labor skillsets, these constraints must be addressed proactively to avoid production bottlenecks or compliance issues.

Key Constraints in Pharmaceutical Manufacturing:

Regulatory Constraints: Compliance with FDA, EMA, and other regulatory bodies requires strict adherence to production protocols, which can limit flexibility in scheduling.

Equipment Constraints: Machinery and tools must be used within specific capacity limits and may require downtime for cleaning or calibration, especially in facilities producing multiple drug types.

Material Constraints: Limited shelf lives and storage requirements for ingredients impose constraints on when and how materials can be used.

Time Constraints: The pharmaceutical industry often operates under tight production timelines, particularly for drugs with high demand or short shelf lives.

PlanetTogether’s integration with ERP systems like Oracle and Kinaxis helps production schedulers manage these constraints effectively. For instance, when a specific piece of equipment is required for a production batch, the integrated system can automatically check equipment availability and flag any upcoming maintenance or calibration needs.

This predictive scheduling can prevent delays and optimize equipment utilization by identifying alternative resources or rescheduling tasks to align with equipment availability.

When regulatory constraints mandate that certain processes or materials are handled by certified personnel, the system’s data synchronization ensures that only qualified staff are assigned to these tasks. By leveraging data from the ERP system, production schedulers can avoid compliance issues and streamline workflows.

Navigating Dependencies: A Layered Challenge in Pharmaceutical Scheduling

In pharmaceutical manufacturing, dependencies are common and often complex, requiring sequential operations or synchronized tasks. Dependencies can be broadly categorized into process, material, and personnel dependencies.

Types of Dependencies:

Process Dependencies: Some production processes must occur sequentially, such as blending before granulation or coating after tablet compression.

Material Dependencies: The availability of certain materials or ingredients may be contingent on other processes, like purification or quality testing.

Personnel Dependencies: Many pharmaceutical tasks demand specific personnel to handle or oversee processes, adding a layer of dependency that impacts scheduling.

PlanetTogether, when integrated with systems like Aveva or SAP, helps production schedulers manage these dependencies by providing a real-time, interconnected view of each step within the manufacturing process. For example, if a batch cannot proceed to the next stage until quality control has approved the previous stage, the scheduler can see this dependency in the system. This visibility allows for smoother transitions between processes and minimizes idle time.

Additionally, with the capability to create linked task sequences, PlanetTogether’s integration with ERP solutions facilitates what is known as “just-in-time scheduling.” This allows production to proceed seamlessly, as each phase is scheduled to begin precisely when resources and approvals are available.

Benefits of Real-Time Integration for Resource and Constraint Management

The real-time aspect of PlanetTogether’s integration with SAP, Oracle, Microsoft Dynamics, or Kinaxis means that data flows continuously between the systems, ensuring production schedules are always based on the latest information. This integration delivers significant benefits for pharmaceutical production schedulers:

Enhanced Decision-Making: Real-time data empowers schedulers to make decisions based on current conditions rather than outdated information, reducing risks associated with resource shortages or sudden changes.

Reduced Idle Time: By aligning resources and dependencies, schedulers can reduce or even eliminate idle time, boosting productivity and throughput.

Proactive Constraint Management: Automated alerts for upcoming constraints, such as maintenance needs or regulatory checks, allow schedulers to address issues before they impact production.

Improved Resource Allocation: Integrated data from PlanetTogether and ERP systems enables more efficient allocation of resources, helping avoid underutilization or bottlenecks.

Compliance and Quality Assurance: Real-time updates ensure compliance requirements are met by assigning the right personnel and resources to each step of production, supporting quality assurance protocols.

Steps to Implement PlanetTogether Integration for Optimal Scheduling

For pharmaceutical companies considering this integrated approach, here’s a general implementation framework:

Assess Scheduling Needs: Identify key resources, constraints, and dependencies unique to your production environment.

Select an Integration-Compatible ERP System: Ensure the ERP solution (e.g., SAP, Oracle, Microsoft, Kinaxis, or Aveva) is compatible with PlanetTogether and can support seamless data integration.

Map Out Resource and Constraint Data Flows: Determine where critical information—such as maintenance schedules, personnel certifications, and material availability—should flow between systems.

Set Up Predictive Scheduling Parameters: Configure PlanetTogether to flag constraints, resource shortages, and dependencies based on real-time data from the ERP system.

Conduct Training for Schedulers and Key Staff: Equip production schedulers with the knowledge to leverage the integrated system’s full functionality.

For pharmaceutical production schedulers, managing resource availability, constraints, and dependencies requires not only a comprehensive understanding of manufacturing dynamics but also access to real-time, interconnected data. With PlanetTogether’s integration with leading ERP systems, schedulers gain visibility, predictive insights, and the agility to respond swiftly to the evolving demands of pharmaceutical manufacturing.

Through effective integration, schedulers can transition from reactive, manual scheduling methods to a proactive, optimized approach that balances resources, adheres to constraints, and respects dependencies. The result is a streamlined, compliant, and responsive production environment capable of meeting the high standards of pharmaceutical manufacturing.

Embracing this integrated technology not only simplifies scheduling but ultimately contributes to a more resilient and efficient production facility, ensuring that medications reach patients safely and on time.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Enhanced Decision-Making Capabilities, Improved Resource Allocation, Pharmaceutical Manufacturing, Reduced Idle-Time, Proactive Constraint Management, Compliance and Quality Assurance

LEAVE A COMMENT