Enhancing Production Scheduling in Industrial Manufacturing: The Power of Integrated APS Solutions

In the realm of industrial manufacturing, the pressure to meet fluctuating demand, minimize downtime, and optimize resource utilization is relentless. Production Schedulers sit at the heart of this challenge, orchestrating complex operations to ensure timely, cost-effective delivery. Yet, with traditional scheduling methods often falling short in today’s dynamic environments, many schedulers are turning to Advanced Planning and Scheduling (APS) systems for a competitive edge.

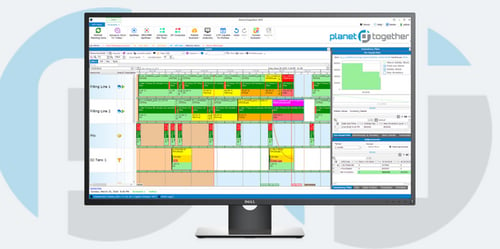

Among these, PlanetTogether APS stands out—especially when integrated with leading ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva. This integration offers unprecedented visibility, automation, and agility, empowering Production Schedulers to make smarter decisions faster.

This blog explores how enhancing production scheduling through such integrations can transform industrial manufacturing operations.

The Challenges Facing Industrial Production Schedulers

Production Schedulers in industrial settings often face several operational hurdles:

Unpredictable demand and supply fluctuations

Limited visibility into real-time shop floor data

Manual or semi-automated scheduling methods

Disconnected planning systems and siloed data

Difficulty managing constraints like equipment capacity, labor, and materials

These challenges can lead to missed deadlines, inefficient resource allocation, increased operating costs, and poor customer satisfaction.

The Case for APS in Industrial Manufacturing

An APS system like PlanetTogether enables schedulers to go beyond basic planning by considering real-time constraints, capacities, and priorities. Key functionalities include:

Finite capacity scheduling

Drag-and-drop Gantt charts

What-if scenario planning

Automated rescheduling

Bottleneck detection

KPI dashboards

But the true power of APS lies in integration—when it's connected with enterprise systems like SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, or Aveva Manufacturing Execution Systems (MES).

Integration: The Game Changer

PlanetTogether + SAP

Integrating PlanetTogether with SAP allows schedulers to seamlessly pull data such as sales orders, inventory levels, production orders, and BOMs. This real-time synchronization ensures that schedules are always based on the latest enterprise data.

Example Benefit:

When a rush order is entered into SAP, PlanetTogether can immediately simulate its impact, assess resource constraints, and suggest optimal adjustments—reducing lead times and avoiding overtime costs.

PlanetTogether + Oracle

Oracle users benefit from integrated scheduling by linking ERP modules like Oracle SCM with PlanetTogether’s advanced logic. Material availability, machine status, and labor capacity can all be factored into scheduling decisions, eliminating guesswork.

Example Benefit:

Integrated alerts in Oracle and PlanetTogether notify schedulers of material shortages or delays, allowing proactive rescheduling that keeps production on track.

PlanetTogether + Microsoft Dynamics

Microsoft Dynamics integration streamlines communication between business and production planning functions. Sales forecasts, master production schedules, and actual work orders automatically update PlanetTogether for real-time responsiveness.

Example Benefit:

Schedulers can instantly assess the impact of delayed supplier deliveries on the production schedule and adjust priorities without re-entering data across systems.

PlanetTogether + Kinaxis

For companies using Kinaxis RapidResponse, integration with PlanetTogether aligns high-level supply chain planning with shop floor execution. Kinaxis provides demand and supply signals; PlanetTogether translates them into actionable production schedules.

Example Benefit:

When Kinaxis forecasts a demand spike for a specific product, PlanetTogether recalibrates resource allocation accordingly, preventing bottlenecks before they occur.

PlanetTogether + Aveva MES

Integration with Aveva MES enables closed-loop production planning. Real-time machine and production status data are fed back into PlanetTogether to support continuous schedule optimization.

Example Benefit:

If a critical machine goes offline, PlanetTogether immediately receives this status from Aveva and generates an alternative schedule to minimize disruption.

Benefits for Production Schedulers

Real-Time Visibility

Schedulers gain a live view of the entire manufacturing process. From incoming orders and raw materials to machine availability and WIP status, everything is visible in one place.

Faster Decision Making

With integrated what-if scenarios and predictive analytics, schedulers can quickly evaluate alternatives and make informed adjustments without manual data crunching.

Improved On-Time Delivery

Optimized schedules aligned with real-world constraints ensure that customer commitments are met more reliably.

Reduced Downtime and Overtime

By proactively identifying and addressing conflicts and bottlenecks, schedulers can reduce idle time and avoid unnecessary labor costs.

Enhanced Collaboration

Cross-functional teams—from procurement to production—benefit from shared visibility and data consistency, leading to better alignment and communication.

Best Practices for Implementing Integrated APS

To fully realize the benefits, here are key considerations:

Define Clear Scheduling Objectives

Identify KPIs such as cycle time reduction, on-time delivery, or machine utilization to guide configuration.

Ensure Data Accuracy and Consistency

Garbage in, garbage out. Clean, real-time data from your ERP/MES systems is crucial for reliable scheduling outcomes.

Involve Cross-Functional Stakeholders

Align IT, operations, planning, and procurement teams early in the integration process to prevent silos and adoption issues.

Provide Training and Change Management

Equip Production Schedulers with proper training to interpret and act on APS insights confidently.

Start Small, Scale Fast

Begin with a pilot line or facility, refine your workflows, and expand gradually to maximize ROI.

For Production Schedulers in industrial manufacturing, the path to enhanced performance lies in integration and intelligence. PlanetTogether APS, when seamlessly connected with platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, delivers exactly that—real-time, responsive, and robust scheduling that drives efficiency, reliability, and profitability.

As the industrial landscape grows more complex, the question is no longer if you should integrate your scheduling tools—it’s how soon you can.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Industrial Manufacturing, Real-time Visibility, PlanetTogether Software, Improved on-time delivery, Integrating PlanetTogether, Enhanced Collaboration, Faster Decision-Making, Reduced Downtime and Overtime

LEAVE A COMMENT