Enhancing Performance Analysis and Strategy for Plant Managers

In the packaging manufacturing industry, where every detail matters, the pursuit of performance optimization is a constant endeavor. Plant Managers are at the heart of this effort, responsible for ensuring operational efficiency, maintaining product quality, and meeting ever-evolving customer demands. However, with an array of complexities ranging from fluctuating supply chains to workforce management, achieving high performance requires not only precise strategy but also the right technological integration.

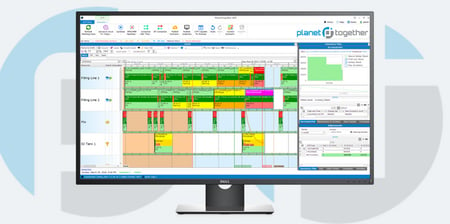

Integrating PlanetTogether with leading ERP systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva offers packaging manufacturers a robust toolkit for refining performance analysis and strengthening their strategic approaches.

Performance Optimization in Packaging Manufacturing

Packaging manufacturing is a multifaceted industry that intersects with multiple sectors, including food and beverage, pharmaceuticals, and consumer goods. This diversity brings about unique challenges in managing demand variability, raw material procurement, production scheduling, and resource allocation. For Plant Managers, one of the primary challenges lies in balancing efficiency with flexibility. The industry’s highly competitive landscape means that plants must continuously improve performance without sacrificing quality, safety, or compliance standards.

To meet these demands, Plant Managers often rely on performance analysis to identify bottlenecks, measure resource utilization, and monitor key performance indicators (KPIs). However, traditional performance analysis tools may lack the depth needed to address modern manufacturing complexities. Integrating PlanetTogether with ERP solutions such as SAP, Oracle, Microsoft, Kinaxis, and Aveva can bridge this gap, delivering real-time insights, predictive analytics, and enhanced data visualization capabilities that empower Plant Managers to make data-driven decisions.

![]()

The Role of PlanetTogether in Packaging Manufacturing

PlanetTogether is a leading Advanced Planning and Scheduling (APS) tool designed to help manufacturers optimize production schedules, reduce lead times, and improve on-time delivery. With its intuitive interface and powerful algorithms, PlanetTogether offers a range of functionalities that are essential for the fast-paced packaging manufacturing environment. These include:

Real-time scheduling that adjusts to demand changes and production delays.

Capacity planning to ensure optimal resource utilization.

Inventory management that aligns stock levels with demand forecasts.

Scenario planning for evaluating the impact of different production strategies.

While PlanetTogether is powerful on its own, integrating it with an ERP system adds a new layer of capability, enabling seamless data flow between planning and execution. For example, by connecting PlanetTogether with SAP, a Plant Manager gains access to a centralized hub where they can analyze everything from production schedules to financials, without switching platforms.

This integration enhances visibility across departments, aligns production activities with business goals, and empowers Plant Managers to implement more effective performance strategies.

Integration with Leading ERP Systems: Enhancing Performance and Strategic Insights

Let’s explore how integrating PlanetTogether with SAP, Oracle, Microsoft, Kinaxis, or Aveva can enhance performance analysis and strategy for Plant Managers in packaging manufacturing.

PlanetTogether and SAP Integration

SAP is a popular choice in the manufacturing sector for its comprehensive suite of enterprise solutions. Integrating PlanetTogether with SAP allows for seamless data transfer, making it possible to combine the strength of SAP’s robust data management with PlanetTogether’s advanced scheduling capabilities.

Example of Benefit: A Plant Manager can use real-time data from SAP to assess material availability and workforce capacity, automatically updating the production schedule in PlanetTogether based on these inputs. This integration reduces downtime by synchronizing material planning and production scheduling, allowing the Plant Manager to make adjustments based on actual inventory and demand data.

Strategic Impact: The SAP and PlanetTogether integration provides Plant Managers with enhanced insights into demand-driven production, improving responsiveness to market shifts. With precise control over lead times and inventory levels, Plant Managers can reduce costs while maintaining service quality.

PlanetTogether and Oracle Integration

Oracle ERP is known for its robust data analytics and financial management capabilities, making it an ideal partner for PlanetTogether in performance optimization. By integrating PlanetTogether with Oracle, Plant Managers gain access to enhanced forecasting tools, financial data, and production metrics in one place.

Example of Benefit: Through Oracle’s analytics, Plant Managers can review the financial impact of various production strategies, allowing them to select cost-effective scheduling options in PlanetTogether. This integration also supports complex “what-if” scenarios, enabling the analysis of potential outcomes based on different resource allocation strategies.

Strategic Impact: With Oracle and PlanetTogether, Plant Managers can balance financial performance with operational efficiency. This integration allows them to analyze production costs, adjust budgets, and predict financial outcomes, fostering more strategic decision-making.

PlanetTogether and Microsoft Dynamics Integration

Microsoft Dynamics is valued for its user-friendly interface and its integration capabilities within the Microsoft ecosystem. Combining Microsoft Dynamics with PlanetTogether allows Plant Managers to tap into a comprehensive suite of productivity tools, including Excel and Power BI, for enhanced data analysis and visualization.

Example of Benefit: Through this integration, a Plant Manager can use Power BI to visualize data from PlanetTogether, gaining real-time insights into production performance, resource utilization, and inventory levels. By integrating with Microsoft Dynamics, data-driven decisions become easier, with KPIs and reports accessible directly through a familiar interface.

Strategic Impact: The combination of PlanetTogether and Microsoft Dynamics fosters a more data-centric approach to production management. Enhanced visualization tools allow Plant Managers to identify trends, predict demand shifts, and adjust production strategies in real-time.

PlanetTogether and Kinaxis Integration

Kinaxis is a recognized leader in supply chain management, offering tools for demand forecasting, capacity planning, and supply chain visibility. Integrating Kinaxis with PlanetTogether enables end-to-end visibility across production and supply chain processes, improving alignment between production schedules and supply chain dynamics.

Example of Benefit: For example, Kinaxis can send demand signals directly to PlanetTogether, allowing the Plant Manager to dynamically adjust the production schedule based on real-time demand fluctuations. This seamless interaction minimizes the risk of overproduction or stockouts, optimizing inventory levels in response to demand.

Strategic Impact: The integration between Kinaxis and PlanetTogether allows for a more agile manufacturing process. By connecting production with supply chain activities, Plant Managers can maintain higher levels of customer satisfaction through on-time delivery, accurate order fulfillment, and minimized stockouts.

PlanetTogether and Aveva Integration

Aveva offers industry-focused solutions for asset performance and operations management, particularly valuable for packaging manufacturers with complex equipment and asset needs. Integrating Aveva with PlanetTogether enhances visibility over equipment utilization, maintenance schedules, and production performance.

Example of Benefit: Aveva’s predictive maintenance capabilities can trigger alerts within PlanetTogether, allowing Plant Managers to schedule preventive maintenance activities without disrupting production. By keeping equipment running smoothly, they can minimize downtime, reduce maintenance costs, and extend equipment life.

Strategic Impact: The Aveva-PlanetTogether integration allows Plant Managers to build a more resilient and efficient production environment. By aligning maintenance schedules with production plans, they can reduce unplanned downtime and enhance the reliability of manufacturing assets.

Implementing a Performance-Driven Strategy with PlanetTogether and ERP Integration

To fully leverage the benefits of integrating PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, Plant Managers should adopt a performance-driven strategy that encompasses both short-term optimizations and long-term improvements. Key steps include:

Define Clear KPIs: KPIs should encompass critical aspects of performance such as production lead time, equipment utilization, on-time delivery rates, and quality control metrics. Integration makes it easier to monitor these KPIs in real time.

Leverage Predictive Analytics: Predictive analytics tools, supported by ERP and PlanetTogether, allow Plant Managers to identify potential issues before they arise. This capability is invaluable for reducing downtime and managing risks effectively.

Enhance Collaboration Across Departments: Integrating PlanetTogether with an ERP system facilitates seamless data flow across departments, fostering collaboration between production, maintenance, finance, and supply chain teams. This cross-functional insight enables more comprehensive performance analysis and streamlined decision-making.

Use Scenario Planning for Strategic Adjustments: Scenario planning tools allow Plant Managers to model the impact of different production strategies, helping them evaluate the potential outcomes of resource reallocation, equipment upgrades, or shifts in scheduling.

Adopt a Continuous Improvement Mindset: Integration isn’t a one-time solution but a continuous improvement journey. Regularly review performance metrics, analyze trends, and adjust strategies to respond to evolving industry challenges and technological advancements.

In the packaging manufacturing industry, where efficiency, precision, and responsiveness are critical, Plant Managers need every advantage to maintain a competitive edge. Integrating PlanetTogether with leading ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva provides the tools needed to streamline performance analysis, enhance strategic planning, and drive continuous improvement.

With enhanced visibility, real-time data insights, and predictive analytics, Plant Managers can optimize production processes, improve resource utilization, and adapt to dynamic market demands, positioning their facilities for sustained success in a challenging industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Inventory Management, PlanetTogether Software, Data-Driven Decisions, Integrating PlanetTogether, Real-Time Insights, Enhanced Predictive Analytics, Packaging Manufacturing, Enhanced Data Visualization Capabilities, Leverage Predictive Analytics

LEAVE A COMMENT