Enhancing Employee Engagement

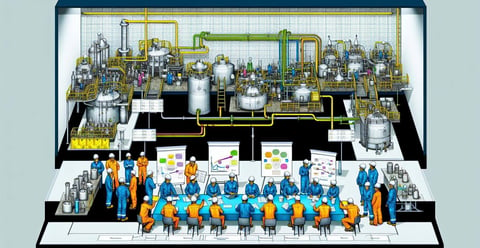

Employee engagement stands as a cornerstone for success in chemical manufacturing. As a plant manager, you understand the pivotal role your workforce plays in achieving operational excellence. One of the key elements that can significantly impact employee engagement is the scheduling process.

In this blog, we look into the importance of transparent scheduling processes and explore how integration between PlanetTogether and leading ERP, SCM, and MES systems can revolutionize workforce management, fostering a culture of transparency and collaboration.

The Significance of Employee Engagement in Chemical Manufacturing

Employee engagement goes beyond mere job satisfaction; it embodies a deep commitment and emotional connection to the organization's goals and values. In chemical manufacturing facilities, where safety protocols, complex processes, and stringent regulations are prevalent, engaged employees are more likely to demonstrate higher levels of productivity, innovation, and safety compliance.

Transparent Scheduling: A Catalyst for Engagement

Transparent scheduling entails providing employees with visibility into their schedules, allowing them to anticipate work shifts, plan personal commitments, and maintain a healthy work-life balance. By fostering transparency in scheduling processes, chemical manufacturing plants can empower their workforce, instill trust, and boost morale. Moreover, transparent scheduling cultivates a culture of accountability and ownership, as employees are aware of their roles and responsibilities well in advance.

Challenges in Traditional Scheduling Methods

Traditional scheduling methods often involve manual processes, fragmented systems, and outdated technologies, leading to inefficiencies, errors, and dissatisfaction among employees. Lack of transparency in scheduling can result in confusion, last-minute changes, and scheduling conflicts, ultimately affecting employee morale and productivity. Moreover, without real-time visibility into production schedules and workforce availability, plant managers may struggle to optimize resources effectively.

Integrating PlanetTogether with ERP, SCM, and MES Systems

To address the challenges associated with scheduling and enhance transparency, chemical manufacturing facilities can leverage integration between PlanetTogether, a robust production planning and scheduling software, and leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva. This integration enables seamless data exchange and synchronization across different functions, providing a unified platform for workforce management and production planning.

Benefits of Integration:

Real-Time Visibility: Integration between PlanetTogether and ERP, SCM, and MES systems offers real-time visibility into production schedules, resource allocation, and workforce availability. Employees can access up-to-date schedules and make informed decisions, reducing uncertainty and enhancing engagement.

Automated Scheduling: By automating scheduling processes, plant managers can optimize resource utilization, minimize downtime, and ensure on-time delivery of products. Automated scheduling algorithms consider various factors such as production capacity, employee skills, and equipment availability, resulting in efficient and fair schedules.

Collaboration and Communication: Integrated systems facilitate seamless collaboration and communication among different departments, enabling proactive problem-solving and alignment of priorities. Employees can communicate scheduling preferences, request time off, and receive notifications about schedule changes, fostering a culture of transparency and openness.

Data-Driven Insights: Integration between PlanetTogether and ERP, SCM, and MES systems generates valuable data insights that enable continuous improvement and decision-making. Plant managers can analyze historical performance metrics, identify trends, and anticipate future demand, thereby optimizing scheduling processes and resource allocation.

Best Practices for Implementing Transparent Scheduling Processes

Involve Employees: Engage employees in the scheduling process by soliciting their feedback, preferences, and concerns. Empower them to participate in decision-making and provide input on scheduling policies and procedures.

Training and Education: Provide comprehensive training and education to employees on the use of scheduling software and tools. Ensure that they understand the benefits of transparent scheduling and how it aligns with organizational goals.

Continuous Improvement: Continuously monitor and evaluate scheduling processes, seeking opportunities for optimization and refinement. Solicit feedback from employees and stakeholders to identify areas for improvement and implement corrective actions.

Embrace Technology: Leverage advanced scheduling software and integration capabilities to streamline scheduling processes and enhance transparency. Stay abreast of technological advancements and industry trends to remain competitive in the market.

Employee engagement is a key determinant of success in chemical manufacturing. Transparent scheduling processes play a crucial role in fostering engagement, trust, and collaboration among employees. By integrating PlanetTogether with leading ERP, SCM, and MES systems, chemical manufacturing plants can revolutionize workforce management, optimize resource utilization, and drive operational excellence.

Embracing transparent scheduling processes is not just a strategic imperative; it's a commitment to empowering and valuing the workforce, paving the way for sustainable growth and success in the industry. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.