Automated Decision-Making in Pharmaceutical Production Planning

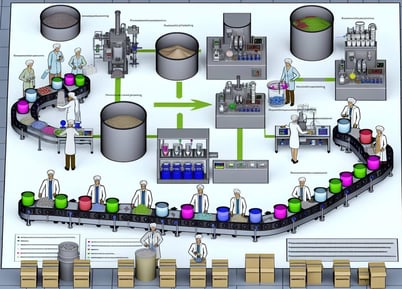

In the intricate world of pharmaceutical manufacturing, where precision, compliance, and efficiency reign supreme, the role of production planners is vital. These professionals shoulder the responsibility of orchestrating the intricate dance of processes that transform raw materials into life-saving medications. However, as the industry evolves, so do the challenges faced by production planners. One of the most promising solutions to these challenges lies in the realm of automated decision-making in scheduling processes.

In this blog, we will explore how automated decision-making, particularly through the integration of advanced planning and scheduling (APS) software like PlanetTogether with enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES) such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, revolutionizes the production planning landscape in pharmaceutical manufacturing facilities.

The Complexities of Pharmaceutical Production Planning

Before looking into the advantages of automated decision-making, it's essential to understand the complexities inherent in pharmaceutical production planning. Unlike many other industries, pharmaceutical manufacturing operates under stringent regulatory frameworks. Every step of the production process, from raw material procurement to distribution, must adhere to strict quality standards and compliance regulations, such as Good Manufacturing Practices (GMP) and FDA guidelines.

Moreover, the pharmaceutical supply chain is inherently complex, with multiple dependencies, variables, and uncertainties. Factors like raw material availability, equipment maintenance schedules, batch sizes, and market demand fluctuations constantly challenge production planners to strike a delicate balance between efficiency, cost-effectiveness, and compliance.

![]()

The Promise of Automated Decision-Making

Automated decision-making in scheduling processes offers a beacon of hope for production planners grappling with these complexities. By leveraging advanced algorithms, real-time data integration, and machine learning capabilities, APS software like PlanetTogether empowers planners to optimize production schedules with unprecedented precision and efficiency.

Integration with ERP, SCM, and MES systems further enhances this capability by providing a holistic view of the entire manufacturing ecosystem. Let's look into how this integration facilitates automated decision-making:

Real-Time Data Synthesis

Integration between APS and ERP systems enables seamless data exchange between production planning and other business functions such as inventory management, procurement, and sales. By accessing real-time data on inventory levels, order statuses, and resource availability, APS software can generate production schedules that align with current demand while minimizing inventory holding costs and stockouts.

Dynamic Optimization

Traditional manual scheduling methods often struggle to adapt to unexpected disruptions or changes in demand. However, automated decision-making empowers production planners to dynamically optimize schedules in response to unforeseen events. By continuously analyzing real-time data and simulating various scenarios, APS software can recommend alternative production plans that maximize resource utilization and minimize downtime.

Compliance Assurance

In the highly regulated pharmaceutical industry, compliance is non-negotiable. Automated decision-making ensures that production schedules adhere to regulatory requirements by incorporating GMP guidelines, batch record documentation, and validation protocols into the planning process. By automating compliance checks and validations, APS software mitigates the risk of non-compliance and ensures product quality and safety.

Resource Allocation Efficiency

Optimizing resource allocation is critical for maximizing production efficiency and minimizing costs. Integrated APS and MES systems provide visibility into equipment availability, maintenance schedules, and workforce capacities, allowing production planners to allocate resources optimally. By considering factors such as equipment downtime, changeover times, and skill requirements, APS software generates schedules that minimize idle time and maximize throughput.

Scenario Planning and Predictive Analytics

Integration with SCM systems enables APS software to leverage predictive analytics and scenario planning capabilities. By analyzing historical data, market trends, and demand forecasts, production planners can anticipate future demand fluctuations and proactively adjust production schedules. Additionally, scenario planning allows planners to simulate various scenarios, such as capacity constraints or supplier delays, to assess their impact on production outcomes and devise contingency plans accordingly.

Integration with Leading ERP, SCM, and MES Systems

The seamless integration between PlanetTogether and industry-leading ERP, SCM, and MES systems, including SAP, Oracle, Microsoft, Kinaxis, and Aveva, further amplifies the benefits of automated decision-making in pharmaceutical production planning. By harnessing the data-rich ecosystem of these enterprise platforms, production planners gain unparalleled visibility and control over the entire manufacturing process.

SAP Integration

SAP's robust ERP platform provides a comprehensive suite of business applications, including production planning, inventory management, and quality control. By integrating with PlanetTogether, SAP users can synchronize production schedules with inventory levels, sales orders, and procurement plans in real-time. This integration streamlines the flow of information across the supply chain, enabling agile decision-making and enhancing operational efficiency.

Oracle Integration

Oracle's SCM solutions offer end-to-end visibility and control over supply chain operations, from procurement to distribution. By integrating with PlanetTogether, Oracle users can optimize production schedules based on demand forecasts, inventory levels, and supplier performance metrics. This integration facilitates seamless collaboration between production planning and supply chain teams, enabling proactive risk management and ensuring on-time delivery of critical materials.

Microsoft Dynamics Integration

Microsoft Dynamics provides a flexible and scalable ERP platform tailored to the needs of pharmaceutical manufacturers. By integrating with PlanetTogether, Microsoft Dynamics users can automate production scheduling while maintaining data integrity and compliance. This integration enables seamless communication between production planning, finance, and sales teams, streamlining operations and accelerating time-to-market for new products.

Kinaxis Integration

Kinaxis offers a cloud-based SCM platform that enables real-time collaboration and decision-making across the supply chain. By integrating with PlanetTogether, Kinaxis users can synchronize production schedules with demand forecasts, inventory levels, and supplier commitments. This integration enhances supply chain visibility and agility, enabling pharmaceutical manufacturers to respond rapidly to changing market conditions and customer demands.

Aveva Integration

Aveva's MES solutions provide real-time visibility and control over manufacturing operations, from shop floor to top floor. By integrating with PlanetTogether, Aveva users can optimize production schedules while monitoring equipment performance, quality metrics, and compliance requirements. This integration facilitates seamless data exchange between production planning and execution, enabling continuous improvement and operational excellence.

Automated decision-making in scheduling processes represents a paradigm shift in pharmaceutical production planning. By leveraging advanced algorithms, real-time data integration, and seamless collaboration across ERP, SCM, and MES systems, production planners can optimize schedules with unprecedented precision, efficiency, and compliance.

The integration between PlanetTogether and industry-leading ERP, SCM, and MES platforms, including SAP, Oracle, Microsoft, Kinaxis, and Aveva, amplifies the benefits of automated decision-making, enabling pharmaceutical manufacturers to stay ahead in an increasingly competitive and complex landscape.

Embracing automation is not just about improving operational efficiency; it's about unlocking new possibilities for innovation, growth, and patient-centricity in the quest to deliver life-saving medications to those who need them most. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Scenario Planning and Predictive Analytics, Compliance Assurance, Real-time Data Synthesis, Dynamic Optimization, Automated Decision-Making, Resource Allocation Efficiency, Pharmaceutical Manufacturing

LEAVE A COMMENT