Enhancing Chemical Manufacturing Supply Chains with Predictive Analytics Integration

Imagine a supply chain where every move is anticipatory, every decision backed by foresight. Welcome to the future of chemical manufacturing, where predictive analytics integration transforms uncertainty into opportunity. As a Supply Chain Manager, you're constantly juggling multiple variables – from fluctuating demand to supply chain disruptions.

In this blog, we look into the transformative power of predictive analytics integration for demand forecasting and supply chain management. Moreover, we'll explore how integrating PlanetTogether with leading ERP systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva can revolutionize your operations.

Understanding the Role of Predictive Analytics

Predictive analytics empowers Supply Chain Managers with the ability to forecast demand, anticipate market trends, and optimize inventory levels. By leveraging historical data, statistical algorithms, and machine learning techniques, predictive analytics provides actionable insights for making informed decisions. However, the true potential of predictive analytics is unlocked when seamlessly integrated into your existing supply chain management systems.

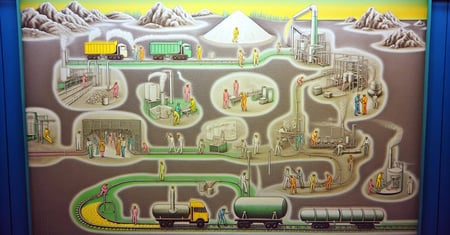

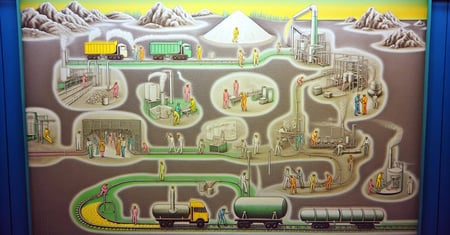

Challenges in Chemical Manufacturing Supply Chains

Chemical manufacturing supply chains are inherently complex, characterized by volatile demand patterns, stringent regulations, and diverse product portfolios. Traditional forecasting methods often fall short in accurately predicting demand, leading to excess inventory, stockouts, and increased operational costs. Furthermore, supply chain disruptions such as raw material shortages, transportation delays, and production bottlenecks can exacerbate these challenges.

Integration of Predictive Analytics with ERP Systems

To address these challenges effectively, Supply Chain Managers can harness the power of predictive analytics by integrating it with their ERP systems. By combining predictive analytics with ERP functionalities, such as inventory management, procurement, and production planning, organizations can achieve greater visibility, agility, and responsiveness across the supply chain.

Integration with PlanetTogether

PlanetTogether is a leading advanced planning and scheduling (APS) software that enables manufacturers to optimize production schedules, minimize lead times, and maximize resource utilization. By integrating PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva, Supply Chain Managers can create a unified platform for end-to-end supply chain management.

Benefits of Integration

Accurate Demand Forecasting: Predictive analytics integration enhances demand forecasting accuracy by analyzing historical data, market trends, and external factors. By aligning production schedules with forecasted demand, organizations can minimize excess inventory and stockouts, leading to improved customer satisfaction and reduced carrying costs.

Real-time Visibility: Integration between PlanetTogether and ERP systems provides real-time visibility into inventory levels, production schedules, and order statuses. This enables Supply Chain Managers to proactively identify potential bottlenecks, allocate resources efficiently, and mitigate supply chain risks.

Optimal Resource Allocation: With predictive analytics insights integrated into production planning processes, organizations can optimize resource allocation based on demand forecasts, production capacities, and lead times. This results in improved operational efficiency, reduced production costs, and faster time-to-market for new products.

Enhanced Collaboration: Integration of predictive analytics with ERP systems fosters collaboration across departments, suppliers, and customers. By sharing actionable insights and forecasts in real-time, stakeholders can collaborate more effectively to anticipate market changes, mitigate risks, and capitalize on emerging opportunities.

The integration of predictive analytics for demand forecasting and supply chain management offers immense potential for optimizing chemical manufacturing operations. By leveraging advanced planning and scheduling software like PlanetTogether and integrating it with leading ERP systems, Supply Chain Managers can unlock actionable insights, improve operational efficiency, and drive sustainable growth.

Embracing predictive analytics integration is not just a competitive advantage – it's a strategic imperative for staying ahead in today's dynamic marketplace.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the chemical industry.

LEAVE A COMMENT