Enhancing Automation in Chemical Manufacturing through Seamless Integration

The pressure to reduce costs, improve efficiency, and enhance safety is immense. With automation at the forefront of innovation, manufacturing IT managers face the challenge of implementing and optimizing solutions that not only streamline operations but also integrate seamlessly with existing enterprise resource planning (ERP) systems.

This task can be particularly complex in chemical manufacturing, where unique regulations, hazardous materials, and stringent quality standards demand a careful approach to technology adoption.

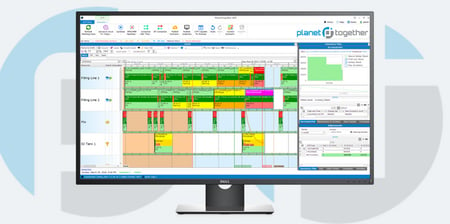

A major advancement for many manufacturing IT managers is the integration of advanced scheduling platforms like PlanetTogether with robust ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva. Integrating PlanetTogether with these ERP solutions can transform automation capabilities, ensuring smoother workflows, minimizing downtime, and enhancing production agility.

In this blog, we’ll explore how combining PlanetTogether with these leading ERP systems can help chemical manufacturers amplify automation capabilities, streamline operations, and foster a more resilient and flexible manufacturing environment.

Automation in Chemical Manufacturing

Automation has become integral to chemical manufacturing due to its ability to:

Increase throughput by reducing manual intervention

Enhance safety through automated hazard controls

Improve quality consistency by minimizing human error

Reduce production and operational costs

However, successful automation goes beyond deploying isolated technology solutions. It requires connecting disparate systems, integrating data flows, and establishing a coherent communication network within the manufacturing ecosystem.

Integrating PlanetTogether’s Advanced Planning and Scheduling (APS) platform with ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, enables a comprehensive, interconnected framework for true automation.

![]()

PlanetTogether and ERP Integration: A Pathway to Enhanced Automation

PlanetTogether, known for its advanced scheduling and optimization capabilities, provides powerful tools for production scheduling, capacity planning, and real-time visibility. When integrated with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, PlanetTogether becomes a linchpin for managing manufacturing workflows, coordinating resources, and enhancing decision-making across the enterprise.

The integration allows data to flow bi-directionally between PlanetTogether and the ERP, providing updated production schedules, material requirements, and inventory levels. This data flow is essential for creating a synchronized, automated production environment. Below, we’ll look at the specific benefits that this integration brings to chemical manufacturing.

Benefits of Enhanced Automation through PlanetTogether and ERP Integration

a) Real-time Data Synchronization

With ERP integration, PlanetTogether has access to real-time data related to orders, inventory levels, production schedules, and capacity constraints. This real-time synchronization enables PlanetTogether to adapt scheduling decisions based on current conditions, providing a true automated planning environment.

For instance, if a critical raw material goes out of stock, PlanetTogether can quickly adjust the schedule and inform other departments through the ERP, ensuring minimal disruptions. This automated response prevents costly delays and keeps production on track.

b) Intelligent Scheduling and Capacity Planning

In chemical manufacturing, some processes have strict dependencies, requiring precise timing and resource availability. Integrating PlanetTogether with an ERP system like SAP or Microsoft Dynamics allows intelligent scheduling that considers these constraints. PlanetTogether can automatically optimize production schedules based on ERP data inputs, ensuring efficient use of machinery and labor while avoiding bottlenecks.

For example, if an ERP like Oracle detects an increase in demand for a specific product, PlanetTogether can dynamically adjust production priorities and resources to accommodate the new demand. This automated adjustment streamlines capacity planning and reduces the need for manual intervention, ensuring that the right resources are available for high-demand products.

c) Improved Inventory Management and Just-in-Time (JIT) Production

Chemical manufacturing often requires strict control of raw materials, especially hazardous ones with specific storage requirements. Integrating PlanetTogether with ERP systems enables a more streamlined approach to inventory management by providing insights into stock levels, expiration dates, and inventory requirements.

PlanetTogether can leverage ERP data to enable Just-in-Time (JIT) production, ensuring that materials are ordered and utilized in sync with production schedules. This integration minimizes waste and reduces the cost of storing excess materials, an important consideration for chemicals that require special handling.

d) Enhanced Compliance and Safety

Automation in chemical manufacturing isn’t just about efficiency—it’s also about safety and compliance. With ERP integration, PlanetTogether can incorporate safety regulations and compliance standards into its scheduling and planning algorithms. By maintaining up-to-date data on hazardous material handling and regulatory requirements from systems like Aveva, PlanetTogether can optimize schedules to adhere to compliance, ensuring a safer workplace.

For example, PlanetTogether can automatically schedule inspections or maintenance on equipment handling hazardous substances, thus minimizing safety risks and aligning with regulatory requirements. ERP integration ensures that any changes in compliance standards are reflected across the production workflow, creating a more compliant and secure automated environment.

Practical Steps for Integrating PlanetTogether with ERP Systems for Automation

Implementing an integrated automation solution requires a phased approach to ensure a smooth transition and effective utilization of both systems. Here’s a step-by-step guide for IT managers:

a) Define Integration Objectives and Key Performance Indicators (KPIs)

Begin by identifying the specific goals of the integration, such as reducing downtime, optimizing inventory, or improving on-time delivery rates. Establishing clear KPIs will allow you to measure the impact of automation and adjust the integration strategy as needed.

b) Evaluate Compatibility and Integration Points

Ensure that PlanetTogether’s APS platform is compatible with the chosen ERP system (SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva). Assess critical integration points such as order data, inventory levels, production capacity, and resource allocation to create a seamless data exchange framework.

c) Design Data Flow and Automation Logic

Map out the data flow between PlanetTogether and the ERP system. Determine what data will flow in real-time, what data requires batch updates, and how each data type will influence automation decisions. Define automation logic based on production rules, material requirements, and regulatory constraints to ensure a comprehensive automated process.

d) Test, Optimize, and Scale

Conduct a thorough testing phase to ensure the integration meets performance and reliability standards. Monitor the impact on production schedules, inventory levels, and compliance. Make necessary adjustments to the integration, and gradually scale the solution across the production facility for consistent results.

Key Takeaways

Integrating PlanetTogether with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva provides chemical manufacturers with a powerful, automated solution. This integration offers:

Real-Time, Data-Driven Decisions: Automated scheduling and capacity planning, informed by up-to-date ERP data.

Enhanced Safety and Compliance: Embedded regulatory checks within the automation framework to prevent accidents and ensure adherence to standards.

Cost-Effective Inventory Management: Optimization of inventory levels through JIT practices, reducing waste and storage costs.

Scalable Automation: A unified system that grows with the organization’s needs, supporting increasingly complex automation workflows.

For Manufacturing IT Managers in chemical facilities, this integration represents a significant step toward an automated, data-driven manufacturing environment. By leveraging PlanetTogether and ERP integration, chemical manufacturers can not only enhance their automation capabilities but also achieve operational resilience, quality control, and regulatory compliance, setting a strong foundation for future innovation.

Embracing this integrated approach to automation positions your facility to adapt quickly to market demands, improve production efficiency, and ultimately thrive in a challenging and highly regulated industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Improved Inventory Management, Real-Time Data Synchronization, Integrating PlanetTogether, Just-in-Time Production, Chemical Manufacturing, Enhanced Compliance and Safety Management, Intelligent Scheduling and Capacity Planning

LEAVE A COMMENT