End-to-End Adoption of Digital and Automation in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, production planners face increasing complexity in managing workflows, optimizing schedules, and ensuring regulatory compliance. The industry is experiencing a paradigm shift, moving from traditional, siloed processes to a fully integrated digital and automated ecosystem.

As pharmaceutical manufacturers strive to enhance efficiency, minimize waste, and improve product quality, end-to-end digitalization and automation have become essential. Advanced solutions like PlanetTogether APS (Advanced Planning and Scheduling), when integrated with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, enable production planners to achieve higher agility, real-time visibility, and optimized resource utilization.

This blog explores the significance of digital transformation in pharmaceutical manufacturing and the role of PlanetTogether APS integration in driving operational excellence.

The Need for Digital and Automation in Pharmaceutical Production Planning

The pharmaceutical industry is bound by stringent regulations, fluctuating demand, and complex production processes. Production planners must deal with multiple challenges, such as:

Regulatory compliance: Maintaining accurate records and traceability for regulatory audits (FDA, EMA, GMP).

Batch production complexity: Managing intricate batch production scheduling to align with demand fluctuations and raw material availability.

Resource constraints: Efficiently allocating labor, equipment, and raw materials while ensuring minimal downtime.

Supply chain disruptions: Addressing global supply chain vulnerabilities while maintaining just-in-time inventory strategies.

Product innovation & speed-to-market: Balancing R&D efforts with commercial-scale production timelines.

The adoption of end-to-end digitalization and automation addresses these challenges by providing real-time data synchronization, predictive analytics, and intelligent scheduling.

How Digital and Automation Transform Pharmaceutical Production Planning

Digital Twin Technology for Real-Time Production Insights

A digital twin is a virtual replica of the manufacturing process, allowing production planners to simulate scenarios, predict bottlenecks, and optimize production runs before actual execution.

Integration with PlanetTogether & ERP systems:

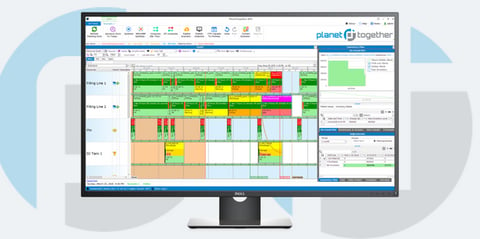

When PlanetTogether APS integrates with SAP, Oracle, Microsoft, Kinaxis, or Aveva, it enables the creation of a real-time digital twin of production scheduling. Planners can adjust variables dynamically, ensuring minimal disruptions while aligning with compliance standards.

AI-Driven Scheduling for Precision Planning

Traditional scheduling methods often rely on static spreadsheets, which can’t adapt to real-time constraints or disruptions. AI-driven scheduling improves efficiency by:

Analyzing historical production data for predictive scheduling.

Recommending alternative workflows during disruptions.

Identifying inefficiencies and reducing cycle times.

PlanetTogether APS + AI-Powered ERP Integration:

By integrating AI-driven APS solutions with ERP systems like Kinaxis or SAP, pharmaceutical production planners gain automated, data-driven scheduling that optimizes machine usage, labor allocation, and material flow.

Predictive Maintenance to Prevent Downtime

Unexpected machine failures can halt pharmaceutical production, causing delays and compliance risks. Predictive maintenance, powered by IoT and AI, helps anticipate equipment issues before they occur.

How PlanetTogether APS Supports Predictive Maintenance:

When PlanetTogether integrates with Aveva or Microsoft Dynamics, it utilizes real-time machine health data to automatically adjust production schedules, preventing costly downtimes while ensuring seamless batch production.

Paperless Manufacturing and Compliance Automation

The pharmaceutical industry heavily relies on paper-based documentation for batch records, compliance reports, and validation logs. Digitizing these processes significantly reduces human errors and enhances traceability.

PlanetTogether APS + SAP Integration for Compliance:

A seamless connection between PlanetTogether APS and SAP enables automated compliance tracking, ensuring that all production steps align with regulatory standards while maintaining complete audit trails.

Smart Supply Chain Synchronization for Material Availability

Production planners must align raw material procurement with batch production schedules to avoid stockouts or overstocking. Automated supply chain synchronization ensures just-in-time material availability.

Kinaxis or Oracle Integration with PlanetTogether APS:

By integrating PlanetTogether with Kinaxis or Oracle, planners can:

Track raw material shipments in real time

Synchronize procurement with production schedules

Predict supply chain risks and optimize inventory buffers

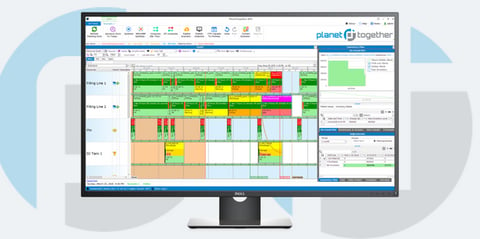

Autonomous Production Adjustments with Real-Time Analytics

Automated real-time analytics dashboards allow production planners to respond dynamically to changes in demand, equipment availability, or regulatory updates.

PlanetTogether APS + Microsoft Power BI:

By linking PlanetTogether APS with Microsoft Power BI, planners gain real-time visibility into scheduling metrics, production KPIs, and capacity utilization, enabling data-driven decision-making.

The Competitive Advantage of Fully Integrated Digital & Automation Systems

Pharmaceutical companies that successfully implement end-to-end digitalization and automation benefit from:

30-50% reduction in production scheduling time

20-40% improvement in equipment utilization

Lower compliance risks with automated tracking

Better supply chain resilience and reduced stockouts

Increased agility to adapt to regulatory or market changes

With the integration of PlanetTogether APS with SAP, Oracle, Microsoft, Kinaxis, or Aveva, pharmaceutical production planners gain the ability to predict, optimize, and control production workflows in a way that was never possible with legacy planning methods.

The pharmaceutical industry is rapidly evolving, and digital transformation is essential. End-to-end digitalization and automation empower production planners with the tools they need to optimize workflows, ensure compliance, and minimize operational risks.

By integrating PlanetTogether APS with SAP, Oracle, Microsoft, Kinaxis, or Aveva, pharmaceutical manufacturers can achieve:

Real-time production visibility

AI-driven precision scheduling

Seamless supply chain synchronization

Predictive maintenance to prevent downtime

Automated compliance tracking

The time to adopt digital-first strategies is now. Pharmaceutical manufacturers that embrace automation and integration will gain a competitive edge in an industry driven by efficiency, quality, and compliance.

Are you ready to take the next step toward intelligent pharmaceutical production planning? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT