Smart Factory Initiatives for End-to-End Connectivity and Visibility

As the demand for agility, flexibility, and responsiveness intensifies, smart factory initiatives are becoming increasingly vital. These smart factory initiatives leverage cutting-edge technologies to enhance connectivity and visibility across the production chain, empowering production schedulers with the tools they need to optimize operations and drive business success.

The rise of Industry 4.0 has ushered in a new era of manufacturing, characterized by interconnected systems, data-driven decision-making, and automation. At the heart of this transformation are smart factory initiatives, which harness the power of digitalization to streamline processes, improve productivity, and deliver greater value to customers.

For production schedulers, the advent of smart factory technologies represents both a challenge and an opportunity. On one hand, the complexity of modern manufacturing operations demands sophisticated scheduling capabilities. On the other hand, advancements in connectivity and visibility offer unprecedented insights and control over production processes.

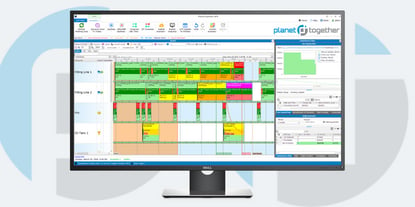

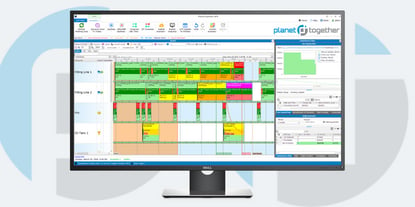

In this blog, we'll explore how production schedulers can leverage smart factory initiatives to achieve end-to-end connectivity and visibility. Specifically, we'll delve into the integration between PlanetTogether, a leading production planning and scheduling software, and various ERP (Enterprise Resource Planning), SCM (Supply Chain Management), and MES (Manufacturing Execution System) systems, including SAP, Oracle, Microsoft, Kinaxis, and Aveva.

Smart Factory Initiatives

Smart factory initiatives encompass a wide range of technologies and strategies aimed at optimizing manufacturing operations. These initiatives typically involve the following key components:

Internet of Things (IoT): IoT sensors and devices are deployed throughout the production environment to collect real-time data on equipment performance, energy consumption, and product quality.

Big Data and Analytics: Advanced analytics tools process large volumes of data generated by IoT devices, enabling predictive maintenance, quality control, and demand forecasting.

Automation and Robotics: Robots and automated systems are employed to perform repetitive tasks with speed, precision, and consistency, reducing labor costs and minimizing errors.

Cloud Computing: Cloud-based platforms provide scalable storage and computing resources for managing and analyzing manufacturing data, enabling remote access and collaboration.

Integration and Connectivity: Seamless integration between disparate systems, such as production planning software, ERP systems, and shop floor control systems, ensures data consistency and enables end-to-end visibility.

Integration Between PlanetTogether and ERP, SCM, and MES Systems

One of the key challenges faced by production schedulers is the siloed nature of manufacturing data. Often, critical information resides in separate systems, making it difficult to obtain a holistic view of operations. Integration between PlanetTogether and ERP, SCM, and MES systems addresses this challenge by enabling seamless data exchange and synchronization.

Integration with ERP Systems (e.g., SAP, Oracle): By integrating with ERP systems, PlanetTogether can synchronize production schedules with sales orders, purchase orders, and inventory data, ensuring alignment between production plans and business objectives.

Integration with SCM Systems (e.g., Kinaxis): Integration with SCM systems enables end-to-end visibility into the supply chain, allowing production schedulers to anticipate material shortages, transportation delays, and other disruptions that could impact production schedules.

Integration with MES Systems (e.g., Aveva): MES integration provides real-time visibility into shop floor operations, including machine status, work-in-progress inventory, and production metrics, enabling production schedulers to monitor performance and make timely adjustments.

Benefits of Integration

Real-Time Data Exchange: Integration allows production schedulers to access up-to-date information on inventory levels, order status, and resource availability directly within the scheduling software, facilitating more accurate decision-making.

Streamlined Workflows: By automating data transfer between systems, integration eliminates manual data entry and reduces the risk of errors, saving time and improving operational efficiency.

Improved Visibility: Production schedulers gain visibility into the entire supply chain, from raw material procurement to finished goods delivery, enabling better anticipation of potential bottlenecks and disruptions.

Enhanced Decision Support: With access to comprehensive, real-time data, production schedulers can make more informed decisions regarding production schedules, resource allocation, and order prioritization.

Empowering Production Schedulers for Success

Smart factory initiatives hold immense potential for enhancing the capabilities of production schedulers and driving operational excellence in industrial manufacturing facilities.

By embracing end-to-end connectivity and visibility through integration between PlanetTogether and ERP, SCM, and MES systems, production schedulers can overcome challenges related to data silos, inefficient workflows, and limited visibility, enabling them to make informed decisions, optimize production schedules, and deliver greater value to their organizations.

As we continue to navigate the complexities of modern manufacturing, it's imperative for production schedulers to leverage the power of smart factory technologies to stay ahead of the competition and achieve sustainable growth in an increasingly dynamic marketplace. By embracing innovation, collaboration, and continuous improvement, production schedulers can play a pivotal role in shaping the future of manufacturing and driving business success.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.