Embracing Digitalization and Industry 4.0

Digitalization and Industry 4.0 have emerged as crucial elements for driving efficiency, quality, and agility. As a Manufacturing IT Manager, your role is pivotal in implementing and integrating digital solutions that support these advancements. Whether you're improving production scheduling, streamlining supply chains, or enhancing real-time data visibility, digitalization offers transformative potential. One key enabler in this journey is leveraging advanced planning and scheduling (APS) software, such as PlanetTogether, and integrating it with enterprise systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva. This blog explores how digitalization and Industry 4.0 impact the packaging industry and how you, as an IT leader, can steer your organization toward a connected, efficient, and resilient future.

Industry 4.0 and Digitalization in Packaging

Industry 4.0 represents the fourth industrial revolution, where cyber-physical systems, IoT, artificial intelligence, and machine learning work together to create a "smart factory." In packaging, Industry 4.0 technologies drive value by enabling:

Real-time data acquisition and analysis: Sensors and IoT devices track machine performance, quality, and throughput in real time.

Automation of repetitive tasks: Robots and automated guided vehicles (AGVs) support tasks such as material handling, packing, and palletizing.

Predictive maintenance: Machine learning algorithms analyze historical and real-time data to predict equipment failures and minimize downtime.

Enhanced supply chain visibility: Integrating ERP and APS systems, such as PlanetTogether with SAP, Oracle, Microsoft, Kinaxis, or Aveva, offers end-to-end visibility across supply chains.

Digitalization in packaging means integrating these technologies to improve efficiency, reduce costs, and elevate quality. As IT managers, you play a crucial role in the deployment and integration of these technologies across production lines and systems, ensuring seamless data flow and cohesive functionality.

The Benefits of Industry 4.0 and Digitalization in Packaging Manufacturing

The packaging industry is increasingly driven by customer demands for speed, customization, and sustainability. Industry 4.0 and digitalization can address these needs by:

Enhancing agility and responsiveness: Digitalized operations can quickly adapt to changes in demand, reducing lead times and improving on-time delivery.

Improving production planning and scheduling: PlanetTogether, when integrated with ERP systems like SAP or Oracle, enables optimized scheduling, balancing production loads, and reducing waste.

Boosting quality and reducing scrap: Advanced analytics help identify the root causes of quality issues, while real-time monitoring allows for immediate adjustments.

Reducing operational costs: Through predictive maintenance and efficient resource allocation, digitalized facilities minimize energy and resource wastage.

For Manufacturing IT Managers, the challenge is enabling these benefits through careful system selection, integration, and support.

![]()

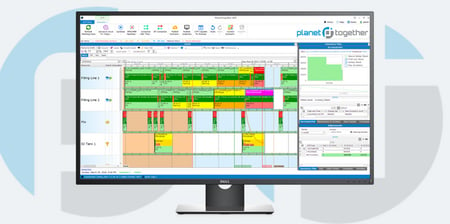

PlanetTogether as a Digitalization Driver in Packaging Manufacturing

PlanetTogether's Advanced Planning and Scheduling (APS) software is specifically designed to support Industry 4.0 initiatives in manufacturing. It offers:

Real-time scheduling: PlanetTogether’s algorithms dynamically adjust schedules based on changes in production, inventory levels, and customer orders.

Enhanced visibility: IT managers can set up integrations to pull data from ERP systems (SAP, Oracle, or Microsoft) and display a comprehensive view of production resources, capacity, and work orders.

Flexibility in integration: PlanetTogether integrates seamlessly with leading ERP and MES platforms, such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, ensuring a unified digital ecosystem.

When integrated with an ERP, PlanetTogether enables IT Managers to reduce production inefficiencies by aligning planning and scheduling with broader business processes, delivering a streamlined, data-driven approach to operations management.

Key Integration Points Between PlanetTogether and ERP Systems

For IT Managers in packaging manufacturing, a successful digitalization journey hinges on the integration between APS software and ERP systems. Some critical integration points include:

Data Synchronization

Integrate production data (e.g., work orders, inventory levels, machine availability) between PlanetTogether and ERP systems like SAP or Oracle.

Ensure real-time data exchange to provide an up-to-date picture of production status and capacity.

Material and Resource Planning

Synchronize Bill of Materials (BOM), routing, and resource availability between ERP systems and PlanetTogether.

This integration helps balance workload across machines and shifts, optimizing resource utilization and reducing downtime.

Performance Monitoring and Analytics

Connect IoT devices and sensors with PlanetTogether to feed real-time data on machine performance and production quality.

This integration enables predictive maintenance, reducing equipment downtime, and ensuring continuous production.

Supply Chain and Inventory Management

Integrate PlanetTogether with supply chain management modules in systems like Kinaxis or Aveva to improve inventory management and demand forecasting.

This coordination ensures raw materials and packaging supplies are available precisely when needed, minimizing stockouts or excess inventory.

As a Manufacturing IT Manager, you’re responsible for aligning these integration points with organizational objectives, selecting technologies that complement existing systems, and ensuring data consistency across platforms.

Overcoming Integration Challenges

Integrating PlanetTogether with ERP systems poses some common challenges:

Data compatibility: Ensure that data from various systems is compatible and accurately mapped across platforms.

Latency and real-time processing: IT managers should consider high-speed data processing and connectivity solutions to minimize latency.

Scalability: Industry 4.0 technologies often introduce large volumes of data, which requires scalable infrastructure to handle growth.

Building a Roadmap for Digital Transformation

As an IT Manager, crafting a roadmap for digital transformation in packaging manufacturing involves:

Assessing Current Systems

Conduct a thorough analysis of current systems, identifying any gaps in data flow or system capabilities that could hinder integration.

Prioritizing Integration Efforts

Focus first on integrations that offer the highest ROI or impact on production efficiency, such as synchronizing PlanetTogether with core ERP functions.

Implementing a Phased Approach

Avoid overwhelming teams by deploying new technologies in phases. Start with high-priority areas and scale as your systems stabilize.

Ensuring Training and Change Management

Successful digital transformation requires a workforce adept at using new systems. Invest in training programs and communicate the value of digitalization to all stakeholders.

Measuring Success in Digital Transformation

Defining and tracking key performance indicators (KPIs) allows you to measure the effectiveness of your digitalization efforts. Some valuable KPIs include:

Throughput improvement: Measure how digital scheduling and planning impacts throughput and cycle times.

Resource utilization: Track machine and labor utilization rates to assess how well resources are used.

Production costs: Monitor costs related to scrap, rework, and material usage.

Downtime reduction: Analyze downtime data from predictive maintenance programs.

Industry 4.0 and digitalization are reshaping packaging manufacturing, enabling greater efficiency, agility, and resilience. For Manufacturing IT Managers, integrating APS software like PlanetTogether with ERP systems is a critical step in this transformation, creating a digital ecosystem that improves real-time decision-making, resource allocation, and quality control.

Through strategic integration, careful planning, and a focus on continuous improvement, you can help your organization navigate the complexities of modern manufacturing and lead the way in the digital age.

As your organization steps into the future, remember that each system integration, data flow, and technology deployment contributes to building a smarter, more efficient packaging facility. The path to full digitalization may be complex, but the benefits make it a journey worth undertaking. Embrace the power of Industry 4.0, and guide your packaging facility to achieve new levels of operational excellence.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Data Synchronization, Packaging Manufacturing, Performance Monitoring and Analytics, Material and Resource Planning, Supply Chain and Inventory Management

LEAVE A COMMENT