Drive Competitive Advantage with PlanetTogether Integration

In today’s market, staying competitive in food and beverage manufacturing requires more than quality products and streamlined operations. A Supply Chain Manager plays a critical role in ensuring that a business not only meets consumer demands but does so efficiently and profitably. With increasing pressure on profitability, sustainability, and adaptability, leveraging digital tools is essential for staying ahead. Integrating advanced planning and scheduling (APS) software like PlanetTogether with leading enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva can unlock a significant competitive advantage. Here's how this powerful combination can transform your supply chain strategy.

The Value of APS and ERP Integration

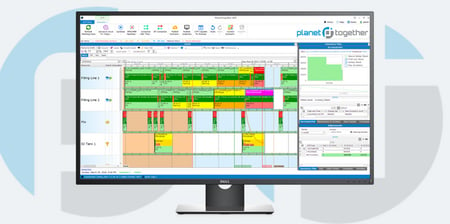

APS software like PlanetTogether offers robust production planning and scheduling capabilities designed to streamline workflows and enhance resource utilization. When integrated with ERP systems, which manage core business processes, APS enables a seamless flow of data across departments, reducing silos and enhancing cross-functional collaboration. For supply chain managers, this integration provides unprecedented visibility and agility, enabling them to make more informed decisions quickly and efficiently.

Imagine being able to not only see production schedules in real time but also instantly account for changes in demand or raw material availability. This capability is essential in food and beverage manufacturing, where demand can be highly variable, supply disruptions can impact ingredients’ availability, and products often have limited shelf lives. APS and ERP integration can ensure that the right resources are allocated to meet consumer demand, maximizing efficiency and minimizing waste.

![]()

Key Benefits of Integrating PlanetTogether with ERP Systems

The integration of PlanetTogether with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva yields a variety of benefits for the food and beverage supply chain, including:

Enhanced Demand Forecasting and Planning

Demand forecasting is challenging, especially in the food and beverage sector, where consumer preferences shift quickly. The integration of PlanetTogether with an ERP system allows you to draw on historical sales data, seasonal trends, and market insights to generate more accurate forecasts. By synchronizing these insights with PlanetTogether’s scheduling capabilities, you can plan production runs more effectively, minimizing stockouts or overproduction.

Improved Inventory Management and Cost Control

Food and beverage products are often perishable, which means inventory control is crucial. Integration allows for synchronized inventory levels, helping managers monitor stock in real time and prevent spoilage or excess stock accumulation. As inventory data from ERP is continuously fed into PlanetTogether, production schedules can be adjusted accordingly, allowing for more precise inventory management. This helps reduce holding costs, eliminate waste, and ensure fresh products reach customers.

Optimized Production Schedules

With integration, production schedules in PlanetTogether can be automatically aligned with the latest demand data from your ERP system. The scheduling engine considers real-time inventory levels, order volumes, equipment availability, and production constraints, enabling a flexible response to market demand fluctuations. By minimizing production bottlenecks and maximizing resource utilization, the entire manufacturing process becomes leaner and more cost-effective.

Enhanced Supplier Collaboration

Working closely with suppliers is essential in food and beverage manufacturing, where ingredient quality and timely delivery are critical. PlanetTogether and ERP integration support supply chain visibility from suppliers to end customers. As demand forecasts and production schedules are shared seamlessly with suppliers, they can plan better and respond to changes more quickly. This improves overall supplier relationships, reduces lead times, and minimizes disruptions.

Compliance and Traceability

In food and beverage manufacturing, regulatory compliance and traceability are top priorities. Integrated systems offer the ability to track raw materials and finished products throughout the supply chain, from sourcing to distribution. This integration enables quick responses to recalls or quality issues, as data can be traced back to its origin in real time. Compliance reporting becomes simpler, with a seamless connection between ERP-stored data and PlanetTogether’s detailed scheduling logs.

Agile Response to Disruptions

Today’s supply chains must be resilient enough to withstand disruptions, whether due to labor shortages, ingredient scarcity, or unexpected demand spikes. With ERP and APS integration, supply chain managers can monitor key metrics such as lead times, inventory levels, and production output in real time. By simulating "what-if" scenarios, PlanetTogether allows you to evaluate alternative production and sourcing strategies, ensuring you have contingency plans ready to deploy.

Practical Steps for Implementing APS and ERP Integration

Achieving a successful integration requires strategic planning and a clear roadmap. Here are some key steps to consider:

Define Your Objectives and KPIs

Start by setting specific, measurable objectives for the integration. Identify key performance indicators (KPIs) such as inventory turnover, production cycle time, and service level improvements. These KPIs will guide your approach and help measure the effectiveness of the integration over time.

Choose the Right Integration Approach

Integration can be approached in various ways, from real-time synchronization to periodic data batch updates. Depending on the complexity and scale of your operations, select an integration approach that fits your needs. Real-time integration is ideal for fast-paced environments with fluctuating demand, while periodic updates may suffice for stable production schedules.

Collaborate Cross-Functionally

Effective integration relies on cross-functional collaboration, involving IT, production, logistics, and finance teams. These stakeholders will ensure that data flows smoothly between systems and that production decisions align with broader business goals. Regular training and communication are essential to help staff understand the benefits of integration and use the systems effectively.

Monitor and Optimize

Once integration is complete, continuously monitor the data flow and performance of both systems. Fine-tune processes based on feedback from users and adjust schedules as necessary to reflect changing demands. Regularly review KPIs to assess whether the integration is achieving the desired impact on efficiency and competitive advantage.

Unlocking Strategic Value: The Competitive Edge of APS and ERP Integration

In the highly competitive food and beverage industry, agility, cost control, and responsiveness to consumer demands are critical for success. The integration of PlanetTogether with an ERP system like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva doesn’t just streamline operations – it provides a strategic advantage. Here’s how:

Enhanced Customer Satisfaction

Meeting demand consistently and delivering quality products on time fosters customer loyalty and satisfaction. With accurate forecasting and optimized schedules, your company can reduce lead times and meet customer expectations, helping secure a solid market position.

Cost Savings

By reducing waste, optimizing inventory, and enhancing production efficiency, APS and ERP integration help keep costs low. Lower costs translate into improved profit margins, which can be reinvested in innovation or passed on to customers, further strengthening your competitive edge.

Sustainable Operations

Consumers are increasingly interested in sustainable practices, and the food and beverage industry is no exception. Integrated systems support sustainability goals by reducing waste and improving resource utilization. Meeting sustainability benchmarks can also attract environmentally conscious consumers and reinforce your brand’s commitment to responsible practices.

Scalability and Growth Potential

Integration prepares your company for growth by providing a scalable foundation for expanding production or entering new markets. As your operations scale, an integrated APS and ERP framework will support streamlined workflows and consistent quality, regardless of production volumes.

In a rapidly changing market, food and beverage manufacturers must embrace digital transformation to remain competitive. The integration of PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva provides a robust framework for achieving operational excellence, agility, and sustainability. For Supply Chain Managers, this powerful combination unlocks new levels of visibility, control, and efficiency, driving a competitive advantage that can make all the difference in today’s market.

Embrace this strategic move and position your organization as an industry leader with an agile, future-ready supply chain. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Enhanced Demand Forecasting and Planning, Optimized Production Schedules, Enhanced Supplier Collaboration, Food and Beverage Manufacturing, Improved Inventory Management and Cost Control, Agile Response to Disruptions, Scalability and Growth Potential

LEAVE A COMMENT