Digitizing Sustainability: How Manufacturing IT Can Tackle Environmental Concerns in Food and Beverage Production

Environmental sustainability is no longer just a buzzword—it's a business imperative. For Manufacturing IT professionals in food and beverage (F&B) manufacturing, the pressure to integrate eco-conscious practices with operational efficiency is mounting. Regulatory bodies, consumer expectations, and corporate ESG (Environmental, Social, and Governance) commitments are converging to make sustainability a top priority.

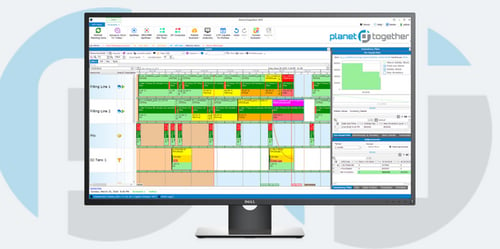

But the challenge is substantial. Food and beverage production generates considerable waste, consumes large volumes of water and energy, and is under scrutiny for carbon emissions. The key to overcoming these challenges lies in digital transformation—particularly in leveraging smart software systems like PlanetTogether APS (Advanced Planning and Scheduling) integrated with enterprise platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva.

This blog explores how Manufacturing IT teams can lead the charge in addressing environmental concerns through intelligent integration and real-time planning.

The Environmental Impact of F&B Manufacturing

The F&B sector contributes significantly to global environmental issues. Key concerns include:

Excessive energy and water usage: Food processing and packaging are energy-intensive, and cleaning operations often demand significant water resources.

Waste generation: From raw material spoilage to packaging waste, inefficiencies in planning can lead to significant losses.

Carbon emissions: Transportation, refrigeration, and production operations all contribute to a sizable carbon footprint.

Regulatory risk: Compliance with environmental regulations like the EPA Clean Water Act or international ISO 14001 standards is increasingly stringent.

To address these, manufacturing IT must shift focus from traditional support functions to proactive enablers of green manufacturing.

IT’s Role in Sustainable Manufacturing

Manufacturing IT teams are in a unique position to drive environmental progress. Their access to data, analytics, and system-wide visibility makes them the architects of intelligent and efficient operations.

By implementing solutions such as PlanetTogether APS and integrating them with ERP and SCM platforms like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, IT leaders can:

Monitor resource usage in real-time

Optimize scheduling to reduce energy-intensive peak loads

Align production planning with sustainability goals

Eliminate inefficiencies and reduce material waste

Let’s explore how these integrations enable such transformations.

The Power of Integration: PlanetTogether + ERP/SCM Systems

Real-Time Data Visibility and Decision-Making

With PlanetTogether APS integrated into ERP platforms like SAP or Oracle, Manufacturing IT gains access to a real-time data stream spanning procurement, inventory, production, and logistics. This live connectivity allows:

Monitoring of energy and water usage at each production stage

Rapid adjustments in scheduling to align with lower-energy operation windows

Enhanced tracking of raw material shelf life, minimizing spoilage

Example: Integrating with Microsoft Dynamics 365 enables planners to automate production runs during off-peak hours when energy rates—and associated emissions—are lower.

Reducing Waste with Smarter Planning

Food spoilage, product overruns, and defective packaging are direct contributors to environmental waste. With PlanetTogether’s AI-driven planning engine, IT teams can reduce overproduction and minimize setup and changeover times.

When integrated with Kinaxis RapidResponse, planners can also simulate supply chain disruptions and model scenarios that optimize both cost and environmental impact.

Outcome: Less waste sent to landfills, and reduced need for costly, resource-intensive rework cycles.

Streamlined Compliance and Reporting

Sustainability reporting is increasingly being codified into law (e.g., EU’s CSRD or U.S. SEC climate-related disclosures). With integration between PlanetTogether and enterprise systems like SAP S/4HANA or Aveva’s industrial software suite, IT teams can:

Automate ESG data capture

Track key performance indicators like carbon emissions per batch

Generate compliance-ready reports with minimal manual intervention

This capability simplifies audits and builds stakeholder trust.

Enabling Circular Manufacturing Through Digital Planning

One of the most ambitious sustainability goals in the F&B sector is transitioning to a circular production model—where waste is repurposed, packaging is recyclable, and energy is renewable.

PlanetTogether, when integrated with platforms like Aveva’s Unified Operations Center, can provide the system orchestration required to:

Route by-products to secondary uses (e.g., animal feed, composting)

Align production runs with availability of renewable energy sources

Support zero-waste packaging initiatives by optimizing material selection and consumption

Case in Point: A snack food manufacturer integrated PlanetTogether with SAP and Aveva to manage sustainability KPIs across facilities. By aligning shift planning with renewable energy availability and reducing packaging waste through accurate demand forecasting, the company cut its environmental footprint by 18% in one year.

From Back-End to Front-Line Change Agents

Manufacturing IT professionals in food and beverage are no longer just back-end system administrators—they’re strategic enablers of environmental sustainability. By integrating advanced planning solutions like PlanetTogether with enterprise platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, IT teams can transform their operations from reactive to proactive, from siloed to connected, and from wasteful to sustainable.

In an industry where margins are tight and environmental scrutiny is intense, the ability to optimize production schedules, reduce waste, and ensure regulatory compliance is more than a competitive advantage—it’s a mission-critical necessity.

It’s time for Manufacturing IT to lead the digital sustainability revolution—one integration at a time.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Reduce Waste, Food and Beverage Manufacturing, Ensure Regulatory Compliance, Monitor Resource Usage in Real-time, Eliminate Inefficiencies and Reduce Material Waste

LEAVE A COMMENT