Digital Transformation Roadmap for Pharmaceutical Manufacturers

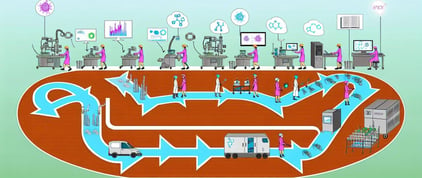

In the pharmaceutical manufacturing landscape, staying competitive and compliant requires more than just traditional methods. The key to long-term success lies in embracing digital transformation. For Operations Directors in pharmaceutical manufacturing facilities, this means adopting advanced planning and scheduling solutions like PlanetTogether and integrating them seamlessly with ERP, SCM, and MES systems.

In this blog, we will explore the essential steps and considerations for building a successful digital transformation roadmap that enhances operational efficiency, reduces costs, and ensures product quality.

Pharmaceutical Manufacturing

Pharmaceutical manufacturing is a complex and highly regulated industry. The demands for quality, precision, and compliance are unparalleled. As an Operations Director, you are well aware of the challenges that come with meeting these demands while maintaining cost-effectiveness and agility. The digital era has ushered in a new set of opportunities and challenges that can significantly impact your manufacturing operations.

Why Embrace Digital Transformation?

Before looking into the specifics of integrating PlanetTogether with ERP, SCM, and MES systems, let's understand why embracing digital transformation is crucial for pharmaceutical manufacturers.

Enhanced Efficiency: Digital transformation streamlines processes, reduces manual intervention, and enhances the overall efficiency of your operations. This translates to faster production cycles and lower production costs.

Real-time Visibility: Integrating systems provides real-time visibility into your entire supply chain, allowing you to make data-driven decisions and react swiftly to disruptions or changes in demand.

Compliance and Traceability: The pharmaceutical industry demands strict compliance with regulatory standards. Digital solutions help in maintaining traceability and ensuring compliance throughout the production process.

Improved Quality Control: Automation and data analytics enable better quality control, minimizing the risk of product defects and recalls.

Cost Reduction: By optimizing resource allocation and minimizing waste, digital transformation helps in reducing operational costs.

Understanding PlanetTogether

PlanetTogether is an advanced planning and scheduling (APS) software solution designed to optimize manufacturing operations. Its capabilities include:

Demand Forecasting: Accurate demand forecasting based on historical data and market trends.

Production Planning: Creating optimized production schedules to meet demand while minimizing costs.

Inventory Management: Optimizing inventory levels to reduce carrying costs while ensuring product availability.

Capacity Planning: Efficiently allocating resources to maximize productivity.

What-if Analysis: Simulating different scenarios to make informed decisions.

Digital Transformation Roadmap

Assess Current Systems and Processes

Before embarking on any digital transformation journey, it's essential to assess your current systems and processes. Identify bottlenecks, inefficiencies, and areas where integration can make a significant impact. Engage with key stakeholders to gather insights into their pain points and requirements.

Define Clear Objectives

Clearly define your objectives for digital transformation. These could include improving production efficiency, reducing lead times, enhancing inventory management, or ensuring better compliance. Having well-defined goals will guide your integration efforts.

Choose the Right Integration Platform

Select an integration platform that suits your needs and integrates seamlessly with both PlanetTogether and your chosen ERP, SCM, and MES systems. Some popular options include SAP, Oracle, Microsoft Dynamics, Kinaxis, Aveva, and others. Ensure that the platform can handle the complexity and regulatory requirements of the pharmaceutical industry.

Data Integration and Connectivity

Effective integration relies on the seamless flow of data between systems. Ensure that you have robust data integration strategies in place. This includes data mapping, data cleansing, and establishing secure connections between systems. PlanetTogether provides APIs and connectors that facilitate integration with various ERP and MES solutions.

Build a Cross-functional Team

Digital transformation is not a solitary endeavor. Assemble a cross-functional team with representatives from operations, IT, compliance, and other relevant departments. This team will play a crucial role in designing, implementing, and maintaining the integrated systems.

Pilot Implementation

Before rolling out the integration across the entire manufacturing facility, conduct a pilot implementation. This allows you to identify any issues or challenges early on and make necessary adjustments. It also provides an opportunity for training and skill development among your team members.

Monitor and Optimize

Once the integration is in place, continually monitor its performance. Utilize the data analytics capabilities of PlanetTogether and your integrated systems to gain insights into your operations. This data-driven approach will enable you to make continuous improvements and stay agile in a dynamic industry.

Ensure Compliance

The pharmaceutical industry is highly regulated. Ensure that your digital transformation roadmap and integrated systems comply with all relevant regulations and standards, such as Good Manufacturing Practices (GMP), FDA requirements, and others.

Benefits of Integrating PlanetTogether with Leading ERP, SCM, and MES Systems

Now, let's look into the specific benefits of integrating PlanetTogether with leading ERP, SCM, and MES systems in the pharmaceutical manufacturing context:

Streamlined Production Planning: By integrating PlanetTogether with your ERP system, you can seamlessly transfer production schedules, resource allocations, and material requirements, ensuring that production plans are synchronized with real-time demand and inventory levels.

Improved Inventory Management: Real-time inventory data from your MES and SCM systems can be integrated with PlanetTogether, allowing for better inventory optimization. This means reduced carrying costs and minimized risk of stockouts or overstock situations.

Enhanced Visibility: Integration with your ERP and MES systems provides end-to-end visibility into your manufacturing processes. This transparency helps in identifying and addressing issues promptly, ensuring smoother operations.

Accurate Demand Forecasting: PlanetTogether can leverage historical data from your ERP and SCM systems to improve demand forecasting accuracy. This leads to more precise production planning and resource allocation.

Efficient Resource Utilization: Integration enables better capacity planning by considering the availability of resources, such as machinery and personnel, as well as production schedules from MES systems. This ensures optimal resource utilization.

Compliance and Traceability: Integration with MES systems ensures that production data, including batch records and quality control information, is captured accurately and in compliance with regulatory standards.

Real-time Decision-making: With data flowing seamlessly between systems, your team can make informed decisions in real time. This is particularly valuable when responding to unexpected events or changes in demand.

Integration Possibilities with Leading Systems

Let's take a closer look at integration possibilities with some of the leading ERP, SCM, and MES systems:

Integration with SAP: PlanetTogether can be integrated with SAP ERP, enabling real-time data synchronization for production planning, resource allocation, and inventory management. This integration ensures that production schedules align with business objectives and customer demand.

Integration with Oracle: Oracle ERP can seamlessly connect with PlanetTogether to provide a unified view of operations. This integration streamlines order processing, inventory management, and financials, ensuring efficient pharmaceutical manufacturing processes.

Integration with Microsoft Dynamics: Microsoft Dynamics ERP integrates well with PlanetTogether, allowing pharmaceutical manufacturers to optimize resource allocation, production schedules, and inventory levels. This integration enhances agility and reduces operational costs.

Integration with Kinaxis: Kinaxis RapidResponse can be integrated with PlanetTogether to provide end-to-end supply chain visibility. This integration allows for faster decision-making, improved demand forecasting, and optimized production planning.

Integration with Aveva: Aveva MES solutions integrate seamlessly with PlanetTogether to provide real-time manufacturing data, quality control information, and production schedules. This integration ensures compliance and enhances operational efficiency.

The digital transformation roadmap for pharmaceutical manufacturers is a journey that requires careful planning, collaboration, and a commitment to continuous improvement. Integrating PlanetTogether with leading ERP, SCM, and MES systems is a pivotal step in this journey, offering numerous benefits such as enhanced efficiency, better visibility, and compliance assurance.

As an Operations Director in a pharmaceutical manufacturing facility, you have the opportunity to lead your organization towards a future where operations are not only efficient but also agile and adaptive to changing market dynamics. By embracing digital transformation and harnessing the power of integrated systems, you can position your facility for sustainable success in the pharmaceutical industry's ever-evolving landscape.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Improved Inventory Management, Accurate Demand Forecasting, Integrating PlanetTogether, Efficient Resource Utilization, Real-Time Decision-Making, Streamlined Production Planning and Scheduling, Enhanced Visibility, Regulatory Compliance and Traceability, Pharmaceutical Manufacturing

LEAVE A COMMENT