Decision-Making to Sustainability

Sustainability has become a core priority for businesses across industries, with medical manufacturing no exception. As a Purchasing Manager in this field, you hold significant responsibility in sourcing materials that meet both quality standards and the organization’s sustainability goals. Balancing these demands while navigating complexities like supply chain disruptions, regulatory compliance, and rising costs can be challenging.

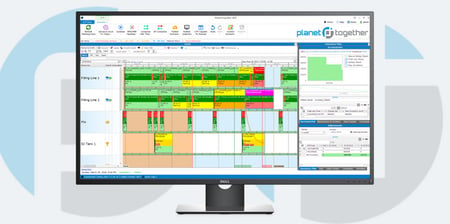

This is where integrating advanced planning and scheduling software, such as PlanetTogether, with ERP systems like SAP, Oracle, or Microsoft, can provide transformative support.

By enhancing visibility, automating processes, and fostering data-driven decision-making, these integrations allow Purchasing Managers to make informed choices that drive sustainability and efficiency. Let’s explore how this integration can empower your role in fostering sustainable procurement practices.

Understanding the Sustainability Imperative in Medical Manufacturing

In the medical manufacturing sector, sustainability isn't just a corporate ideal—it’s becoming a regulatory expectation. From reducing carbon footprints to sourcing eco-friendly materials, sustainable procurement can yield benefits like reduced costs, increased regulatory compliance, and strengthened brand reputation. Yet, the journey to sustainable purchasing is often complex due to specific industry standards for safety and precision, where even slight deviations can have significant consequences.

Key areas where sustainability intersects with purchasing in medical manufacturing include:

Materials Selection: Using bio-based, recycled, or responsibly sourced materials wherever possible.

Supply Chain Transparency: Collaborating with suppliers who adhere to sustainable practices.

Waste Reduction: Minimizing excess materials and optimizing inventory to reduce waste.

PlanetTogether helps simplify these processes by integrating seamlessly with leading ERP systems like SAP, Oracle, and Microsoft, empowering Purchasing Managers to make informed, sustainable decisions with ease.

![]()

Leveraging PlanetTogether Integration for Sustainable Decision-Making

The complexity of sustainability-focused decision-making in medical manufacturing requires robust data, predictive analytics, and automated insights. By integrating PlanetTogether with ERP systems, companies achieve enhanced data flow, real-time visibility, and improved planning capabilities.

Real-Time Data Synchronization for Material Sourcing

When PlanetTogether is integrated with an ERP system, like SAP, you gain access to synchronized, real-time data on available materials, supplier performance, and environmental metrics. For example:

Supplier Assessment: Data about supplier environmental impact, waste reduction efforts, and adherence to sustainability practices is readily available, aiding in supplier selection aligned with your sustainability goals.

Inventory Optimization: PlanetTogether can pull real-time inventory levels from SAP or Oracle to avoid over-ordering, helping prevent waste and reduce storage-related emissions.

This real-time integration ensures you can base purchasing decisions on up-to-date data, enabling the alignment of procurement processes with sustainability standards.

Predictive Analytics and Forecasting with Microsoft Integration

Incorporating predictive analytics is invaluable for anticipating demand fluctuations and adjusting procurement strategies accordingly. With a Microsoft-PlanetTogether integration, you can use advanced forecasting models to anticipate material needs without overstocking, thus minimizing waste and excess energy use.

Demand Forecasting: By aligning data from PlanetTogether with Microsoft’s analytics capabilities, you can accurately forecast demand based on historical patterns, current trends, and production schedules.

Waste Minimization: This proactive approach to procurement helps eliminate over-purchasing, reducing surplus materials and associated waste—a crucial aspect of sustainability.

Predictive analytics also allow you to adjust procurement decisions in real time, which is critical for keeping pace with evolving environmental regulations and customer preferences.

Enabling Supplier Collaboration through PlanetTogether’s Extended ERP Integration

One of the most significant steps toward sustainability in procurement is fostering collaboration with suppliers who share similar sustainability commitments. PlanetTogether’s integration with ERP systems enables a more efficient and transparent supplier collaboration process, essential for sustainable procurement.

Supplier Performance and Compliance Monitoring

With the integration, you can monitor supplier compliance with sustainability metrics directly in the system, improving transparency and decision-making. For instance, an Oracle-PlanetTogether integration can provide:

Sustainability Scorecards: Displaying supplier adherence to sustainable practices, from carbon footprint data to waste management, so you can prioritize suppliers that meet the organization’s sustainability targets.

Automated Alerts: Notifying you if a supplier’s practices diverge from established sustainability goals, enabling you to address issues or reassess suppliers as needed.

By aligning supplier data in PlanetTogether with ERP analytics, you’re equipped to build stronger partnerships with suppliers committed to sustainable practices, driving a greener supply chain.

Collaborative Planning with Kinaxis for Supply Chain Resilience

Integrating PlanetTogether with Kinaxis can be particularly powerful in managing disruptions that threaten sustainability goals. This integration provides enhanced capabilities for scenario planning and collaborative decision-making, fostering supply chain resilience.

Risk Mitigation: When disruptions occur, you can quickly analyze alternatives for sustainable sourcing through PlanetTogether’s scheduling and Kinaxis’ risk assessment tools.

Alternative Supplier Selection: In case a primary supplier fails to meet sustainability standards or is impacted by a disruption, you can identify alternative suppliers who align with the organization’s sustainability goals.

Collaborative planning tools enable proactive decision-making, allowing you to source materials responsibly without compromising production timelines.

Enhancing Operational Efficiency to Reduce Environmental Impact

Efficient procurement practices have a direct impact on environmental sustainability. By integrating PlanetTogether with ERP systems, you can optimize purchasing processes and minimize resource waste, translating into reduced environmental impact.

Automated Workflows for Sustainability

Automation reduces the manual workload, freeing up time to focus on high-value activities like supplier development and sustainability analysis. For instance:

Automated Reordering: Integrated workflows between PlanetTogether and ERP systems enable automated reordering of sustainable materials based on inventory thresholds, ensuring continuous production while reducing excess inventory.

Optimized Order Quantities: Integration allows you to automatically adjust order sizes based on demand forecasts and production schedules, reducing unnecessary storage, transportation emissions, and potential waste.

Automated workflows streamline procurement processes, reducing human error and fostering sustainability by promoting efficient, lean procurement practices.

Data-Driven Insights to Guide Sustainability Initiatives

Data is the foundation of sustainable decision-making. PlanetTogether’s integration with ERP systems offers Purchasing Managers comprehensive insights into purchasing patterns, supplier compliance, and inventory levels. Through real-time data access, you can:

Identify Sustainability Gaps: Spot inefficiencies in the procurement process that result in excess resource use or emissions.

Track Sustainability KPIs: Monitor key performance indicators (KPIs) like waste reduction, energy consumption, and supplier sustainability compliance.

Generate Sustainability Reports: With integrated data across PlanetTogether and ERP systems, generating reports to communicate sustainability achievements to stakeholders becomes seamless.

This data-centric approach provides the necessary visibility and accountability to continually refine and enhance sustainable procurement strategies.

Embracing Continuous Improvement and Sustainability in Procurement

Sustainability is not a static goal—it requires continuous assessment and improvement. By leveraging PlanetTogether’s integration with ERP systems like SAP, Oracle, Microsoft, or Kinaxis, your procurement decisions are backed by real-time, data-driven insights and enhanced automation. This alignment not only helps achieve your sustainability targets but also ensures continuous improvement.

Creating a Culture of Sustainability

Encouraging a sustainability-focused culture among the procurement team and suppliers is essential for long-term impact. With a unified data platform:

Transparent Communication: You can easily share sustainability goals and performance metrics across the team, fostering a collective commitment to sustainable procurement.

Supplier Training: Educate suppliers on sustainability expectations and support them in improving practices, aided by PlanetTogether’s data-sharing capabilities with ERP systems.

By prioritizing a sustainable culture, you can elevate the procurement function to be a strategic contributor to your organization’s overall environmental goals.

The role of a Purchasing Manager extends beyond cost management to include sustainability as a core objective. With PlanetTogether’s integration with ERP systems like SAP, Oracle, Microsoft, and Kinaxis, you gain powerful tools for data-driven decision-making, enhanced supplier collaboration, and continuous operational improvement.

These integrated solutions empower you to source responsibly, optimize procurement processes, and reduce waste, all while meeting stringent medical manufacturing standards. As sustainability continues to define the future of manufacturing, embracing these integrated tools can position your procurement function as a key driver of environmental responsibility and operational excellence.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the medical industry.

Topics: PlanetTogether Software, Real-Time Data Synchronization, Integrating PlanetTogether, Collaborative Planning, Supply Chain Resilience, Medical Manufacturing, Material Sourcing and Inventory Optimization, Predictive Analytics and Forecasting, Supplier Performance and Compliance Monitoring

LEAVE A COMMENT