As a Plant Manager in a packaging manufacturing facility, you're constantly facing the challenge of improving efficiency while maintaining product quality. One of the key areas where you can make significant strides in achieving this goal is through scheduling optimization. In today's fast-paced manufacturing environment, where every minute and every resource counts, having the right tools to visualize and optimize your scheduling process can be a game-changer.

This blog will look into the world of data visualization for scheduling optimization, with a focus on integration between PlanetTogether and leading Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and more. We will explore the benefits, challenges, and best practices of integrating these systems and leveraging data visualization tools to streamline your packaging manufacturing operations.

What is schedule optimization?

Schedule optimization refers to the process of improving and refining schedules to achieve better efficiency, productivity, or other specified objectives. This can apply to various contexts, such as project management, workforce scheduling, transportation planning, and more. The goal is to create schedules that meet specific criteria, constraints, and goals while minimizing costs or maximizing desired outcomes.

The Importance of Scheduling Optimization

Before we dive into the specifics of data visualization and system integration, let's first understand why scheduling optimization is so crucial for packaging manufacturing plants.

Minimizing Downtime

Downtime is the nemesis of productivity. In a packaging facility, machinery and equipment must run at optimal efficiency to meet production targets. A well-optimized schedule ensures that machines are utilized to their fullest potential, minimizing downtime due to changeovers, breakdowns, and other disruptions.

Efficient Resource Allocation

Scheduling optimization allows you to allocate resources such as labor, raw materials, and energy more effectively. By aligning resource availability with production demand, you can reduce waste and cut operational costs.

Meeting Customer Demand

In today's competitive market, meeting customer demand on time is crucial. An optimized schedule ensures that your products are manufactured and delivered when your customers expect them, improving customer satisfaction and loyalty.

Adaptability to Change

The manufacturing landscape is constantly evolving. Scheduling optimization enables you to respond quickly to changes in demand, supply chain disruptions, and other unforeseen events, ensuring your plant remains agile and competitive.

Leveraging Data Visualization for Scheduling Optimization

Now that we've established the significance of scheduling optimization let's explore how data visualization can be your secret weapon in achieving this goal.

Real-Time Visibility

Data visualization tools provide real-time insights into your packaging manufacturing process. You can monitor machine performance, production progress, and resource utilization at a glance. This visibility enables you to make informed decisions on the fly.

Predictive Analytics

Advanced data visualization solutions like PlanetTogether can integrate with predictive analytics models. This means you can anticipate production bottlenecks, equipment failures, and supply chain issues before they occur. By acting proactively, you can prevent costly disruptions.

Scenario Analysis

Data visualization allows you to run "what-if" scenarios effortlessly. You can experiment with different production schedules, resource allocations, and production sequences to identify the most efficient and cost-effective options.

KPI Tracking

Key Performance Indicators (KPIs) are essential for measuring the success of your manufacturing operations. Data visualization tools can help you track KPIs like OEE (Overall Equipment Effectiveness), on-time delivery, and production costs, enabling you to continuously improve your processes.

Integration with ERP, SCM, and MES Systems

Now, let's address the elephant in the room—how do you seamlessly integrate data visualization for scheduling optimization with your existing ERP, SCM, and MES systems?

PlanetTogether Integration

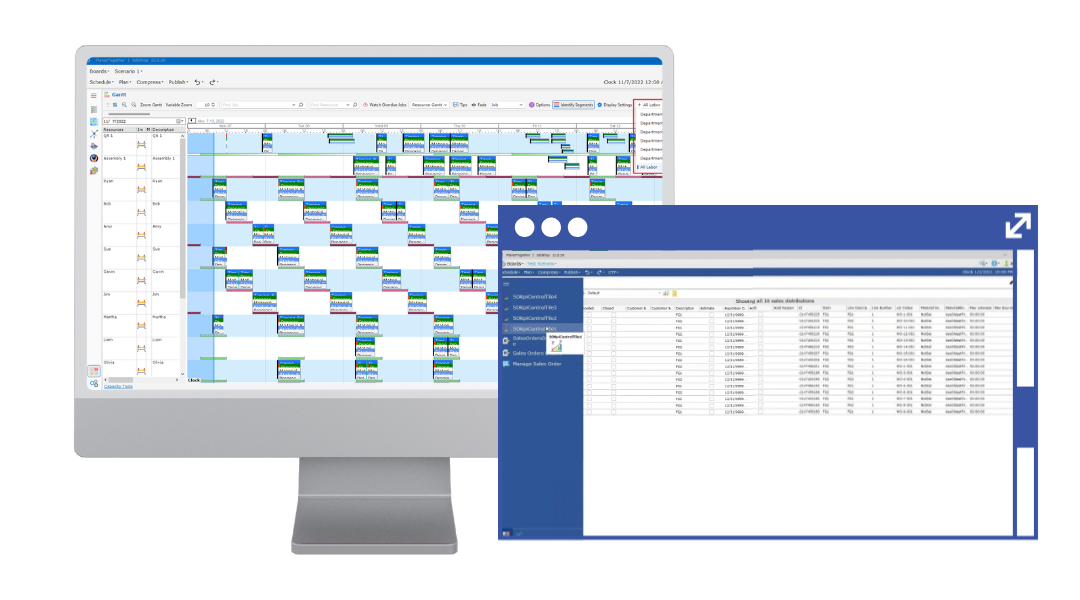

PlanetTogether is a powerful Advanced Planning and Scheduling (APS) software known for its capabilities in optimizing production schedules. It offers various integration options to connect with your existing systems. Here's how you can achieve this:

SAP Integration

Integrating PlanetTogether with SAP is a common practice in manufacturing. By connecting your APS software with SAP, you can ensure that your scheduling decisions align with your business's financial and resource constraints.

Oracle Integration

Similar to SAP, Oracle can be seamlessly integrated with PlanetTogether. This integration enables you to synchronize data between your scheduling system and Oracle's robust suite of business applications.

Microsoft Integration

For those using Microsoft Dynamics, integrating PlanetTogether is straightforward. You can harness the power of Microsoft's technology stack while benefiting from advanced scheduling capabilities.

Kinaxis Integration

Kinaxis RapidResponse is a popular SCM solution. Integrating it with PlanetTogether allows for end-to-end visibility and synchronization of your supply chain and manufacturing operations.

Aveva Integration

Aveva MES, formerly Wonderware, can be tightly integrated with PlanetTogether to bridge the gap between your scheduling and execution systems. This integration ensures that your production plans are executed smoothly on the shop floor.

Benefits of Integration

The advantages of integrating PlanetTogether with your ERP, SCM, or MES systems are manifold:

Data Consistency

Integration ensures that data is consistent across all systems. This means you can trust that the information you see in your data visualization tools aligns with your core business data.

Streamlined Operations

Synchronized data between your scheduling and core systems facilitates smoother operations. Changes made in one system are reflected in the others, eliminating the need for manual data entry and reducing errors.

Improved Decision-Making

Access to real-time data from your ERP, SCM, MES, and scheduling systems empowers you to make informed decisions quickly. This is especially critical in rapidly changing manufacturing environments.

Enhanced Collaboration

Integration fosters collaboration across departments. When your scheduling team, procurement team, and production team share the same data, they can work together more effectively to achieve common goals.

Challenges and Best Practices

While integrating PlanetTogether with your existing systems offers numerous benefits, it's not without its challenges. Here are some common hurdles and best practices to overcome them:

Data Mapping

Ensure that data from your ERP, SCM, and MES systems is accurately mapped to the fields in PlanetTogether. A well-defined data mapping strategy is crucial for a successful integration.

Change Management

Expect resistance to change, especially from employees who are accustomed to the existing systems. Implement a robust change management plan to help your team adapt to the new processes.

Training and Support

Invest in training your team on how to use the integrated system effectively. Provide ongoing support to address any issues or questions that arise.

Scalability

Consider the scalability of your integrated system. As your business grows, your scheduling and data visualization needs may evolve, so ensure that the chosen solution can adapt accordingly.

In the competitive world of packaging manufacturing, scheduling optimization is non-negotiable. Leveraging data visualization tools, particularly when integrated with your ERP, SCM, and MES systems, can be a game-changer for your plant.

PlanetTogether, with its robust scheduling capabilities, offers a powerful solution for improving efficiency and reducing costs. When seamlessly integrated with systems like SAP, Oracle, Microsoft, Kinaxis, Aveva, and others, it becomes a potent tool that empowers you to make data-driven decisions, optimize resource allocation, and meet customer demand with ease.

As a Plant Manager, embracing data visualization for scheduling optimization and harnessing the power of integration will not only improve your plant's performance but also position your facility for success in an ever-evolving manufacturing landscape. By staying ahead of the curve and making informed decisions, you can ensure that your packaging manufacturing plant remains competitive and efficient for years to come.

Topics: PlanetTogether Software, Data Consistency, Integrating PlanetTogether, Streamlined Operations, Enhanced Collaboration, Improved Decision-Making and Agility

LEAVE A COMMENT