Maximizing productivity within your manufacturing operation is challenging without a proper production plan - especially during this time period. As demand uncertainty is prevalent as of right now, there is much to consider when attempting to maximize efficiency within your operation. This process is much easier said than done, considering that production has a lot more to account for right now as opposed to a few months prior. The production plan needs to ensure that components are readily available when and where they are needed.

With uncertain demand and a particular volatile economy, how are you able to locate the most advantageous production plan during the coronavirus pandemic? As many operations managers are running into this issue, a number of them are finding themselves running into Advanced Planning and Scheduling (APS) Software as a potential solution. While there are other production scheduling softwares that are available to aid during this crisis, Advanced Planning and Scheduling (APS) is by far the most advanced and complex approach to labor scheduling, inventory reduction, improved delivery times, and optimizing equipment utilization. Therefore, within this blog, we are going to discuss how a production plan works and how you can locate the most advantageous schedule.

Adequately Planning Work Within Manufacturing

In order to experience any benefits associated with APS, it is essential to understand how a production plan works within a manufacturing operation.

- Material Ordering - Materials that are further away or not readily available at certain times need to be order within an earlier time period. This is to ensure that the materials arrive on time and will be ready for production. This is one of the largest concerns pertaining to supply chain during this time - having adequate materials within the time frame requested. APS is able to aid with this concept through locating the most advantageous schedule for you and ultimately ordering your materials within the timeframe requested.

- Equipment Procurement - Procuring specialized equipment and tools in order to effectively initiate production may require a much longer lead time. This is another challenging concept during this time considering that some manufacturers are switching up what they produce. You must keep in mind that equipment may have to be custom made or is considered difficult to set up. Accounting for this is a must within your production plan.

- Bottlenecks - Within any production or manufacturing operation, there will always be bottlenecks. Attempting to locate ways to reduce them or rid yourself of them is a constant journey. Any constraints or restrictions within production should be evaluated in advance and you should either plan around them or attempt to eliminate them before production begins. Especially during this time, attempting to reduce constraints is absolutely essential and may aid your production facility immensely.

A software that can effectively establish an effective production plan is PlanetTogether’s advanced planning and scheduling software (APS). Advanced planning and scheduling software (APS) can effectively account for changes within production and generate schedules that are optimized for efficiency and waste reduction. APS has become a necessity for manufacturing operations around the globe that are seeking to take their operation to the next level.

Advanced Planning and Scheduling Software

Advanced Planning and Scheduling (APS) software has become a must for modern-day manufacturing operations due to customer demand for increased product mix and fast delivery combined with downward cost pressures. APS can be quickly integrated with a ERP/MRP software to fill gaps where these system lack planning and scheduling flexibility and accuracy. Advanced Planning and Scheduling (APS) helps planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans.

- Create optimized schedules balancing production efficiency and delivery performance

- Maximize output on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

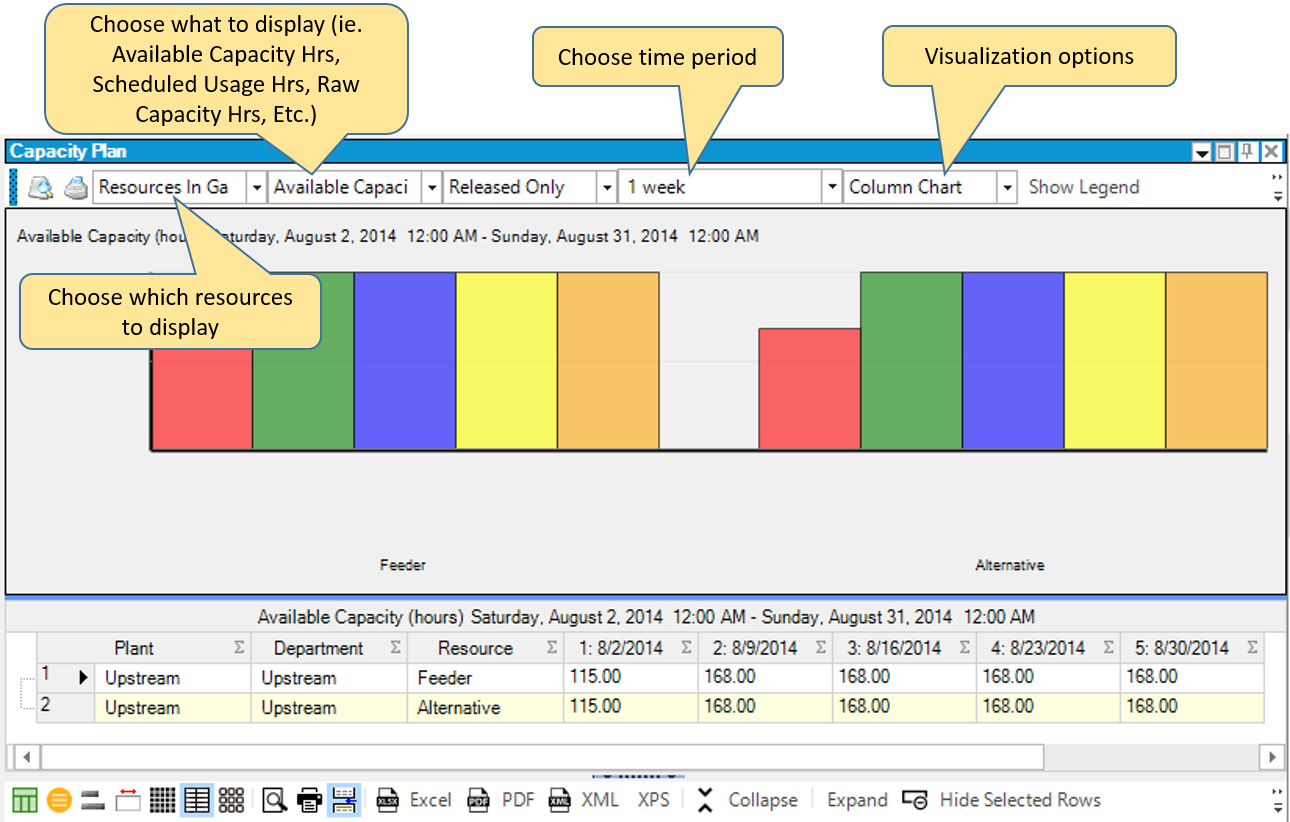

- Provide company-wide visibility to capacity

- Enable scenario data-driven decision making

Implementation of Advanced Planning and Scheduling (APS) software will take your manufacturing operations to the next level of production efficiency, taking advantage of the operational data you already have in your ERP.

Related Multi PlantVideo

APS Resources