Clean Labels, Clear Data: How Manufacturing IT Can Lead the Way with Smart Integration

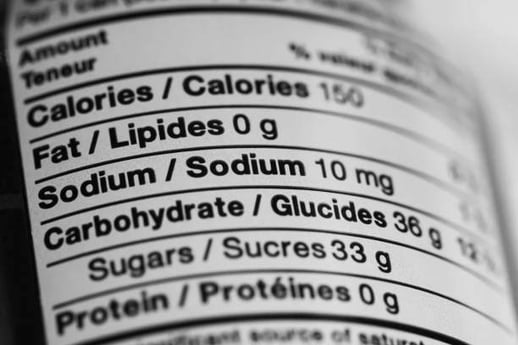

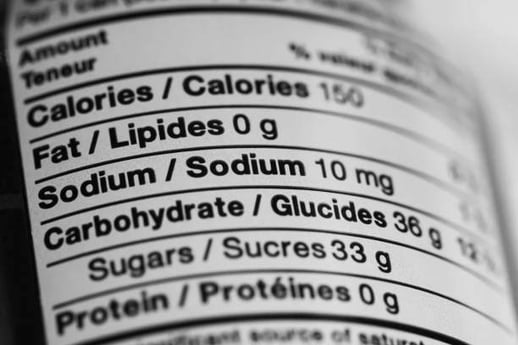

In food and beverage manufacturing, clean labels are no longer a niche trend—they’re a non-negotiable. Consumers are demanding transparency, simple ingredients, and truthful labeling. That shift is driving a seismic transformation in how manufacturers manage recipes, ingredients, and traceability.

But behind every clean label on a shelf is a complex digital ecosystem that must be streamlined and connected. For Manufacturing IT Managers, the challenge isn’t just keeping up—it’s building a resilient, responsive infrastructure that enables clean-label production without compromising efficiency.

This is where PlanetTogether Advanced Planning and Scheduling (APS), integrated with platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, becomes not just helpful—but essential.

The Clean Label Imperative

Clean labeling boils down to this: fewer ingredients, clearer sourcing, and more transparency. That translates to:

Removing artificial preservatives, dyes, and additives

Simplifying product formulations

Using non-GMO and organic ingredients

Emphasizing traceability and accountability across the supply chain

For IT teams, this adds layers of complexity to the already intricate web of production. Ingredient substitutions must be fast, sourcing must be agile, and traceability must be airtight. You’re no longer just managing systems—you’re enabling a new business model.

Complexity Behind Simplicity

What looks simple to the consumer is often a data and operations challenge for the business:

Multiple SKU variants to meet different labeling requirements (e.g., gluten-free, organic, allergen-free)

Supplier diversity to support flexible sourcing of clean ingredients

Shorter shelf lives and stricter storage requirements

More frequent recipe changes and versioning

These aren’t just formulation concerns—they are deeply tied to your production planning, inventory management, and data integration infrastructure.

The Role of Manufacturing IT: Clean Label Champions

Manufacturing IT plays a crucial role in enabling the clean label transformation:

Data Stewardship: Ensuring ingredient data is accurate, version-controlled, and accessible across systems

System Interoperability: Creating seamless communication between MES, ERP, APS, and supplier systems

Change Management: Supporting R&D and operations with agile, responsive systems

Traceability Infrastructure: Ensuring every ingredient’s origin and journey is digitally traceable

This is where a tightly integrated APS platform like PlanetTogether, plugged into your ERP and MES systems, becomes a powerful enabler.

Integration with ERP Systems: The Backbone of Clean Label Execution

Let’s look at how PlanetTogether APS enhances your clean-label strategy when integrated with core platforms:

SAP + PlanetTogether: Agile Planning with Full Traceability

SAP is a robust ERP system, but when planning becomes complex due to variable ingredient availability or regulatory-driven reformulations, PlanetTogether steps in.

PlanetTogether pulls real-time data from SAP on raw material availability, shelf life, and supplier changes

It then dynamically adjusts production schedules to reflect new recipe versions or sourcing shifts

Result: IT ensures that clean-label changes are executed efficiently and without disruptions

Oracle + PlanetTogether: Synchronizing R&D and Operations

Oracle systems are often used in environments with extensive regulatory needs. Clean label transitions require faster go-to-market timelines.

PlanetTogether receives formulation updates directly from Oracle-based PLM systems

Simulations can be run to test production feasibility before recipes are finalized

Result: IT ensures the R&D-to-production handoff is seamless and rapid

Microsoft + PlanetTogether: Enabling Data-Driven Flexibility

For manufacturers using Microsoft Dynamics 365, integrating with PlanetTogether enables rapid scenario planning.

When ingredients change due to clean-label reformulations, schedules are re-optimized on the fly

IT can visualize bottlenecks, batch traceability, and inventory gaps—all in a centralized planning interface

Result: Clean-label recipes can be rolled out confidently, with minimal downtime

Kinaxis + PlanetTogether: Supply Chain Visibility Meets Shop Floor Execution

Kinaxis is powerful for supply chain planning. When integrated with PlanetTogether:

Supply-side ingredient changes flow into finite capacity planning tools

IT can bridge long-range supply disruptions with short-term production agility

Result: End-to-end visibility across the clean-label supply chain—from supplier to shop floor

Aveva + PlanetTogether: MES Synergy for Quality Control

Aveva’s MES systems handle shop-floor execution. When paired with PlanetTogether:

Real-time machine and quality data feed into the planning engine

PlanetTogether adjusts schedules in response to quality holds or yield variability

Result: IT ensures clean-label production maintains compliance and quality standards

Benefits of PlanetTogether Integration for Clean Label Initiatives

| Challenge |

PlanetTogether Integration Solution |

| Ingredient substitutions |

Dynamic re-scheduling based on material availability |

| Recipe versioning |

Version-controlled BOMs with rapid schedule updates |

| Traceability compliance |

Lot-level tracking and integration with ERP quality modules |

| Supplier disruptions |

What-if scenarios with impact on scheduling and inventory |

| Collaboration across teams |

Centralized planning data visible to IT, QA, Ops, and Procurement |

Clean labeling is here to stay, and it’s more than a marketing trend—it’s a redefinition of operational excellence. For Manufacturing IT Managers, this is a chance to lead the charge in enabling cleaner, leaner, more transparent production environments.

By integrating PlanetTogether with platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, IT can create a resilient infrastructure that supports clean-label demands without sacrificing efficiency.

Because in the end, clean labels require clean data—and that’s your domain.

Ready to modernize your planning systems for clean-label production?

Let’s talk about how PlanetTogether integration can help you move faster, stay compliant, and deliver the transparency your consumers demand. Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT