Circular Economy Practices: Transforming Sustainability through Integration

Sustainability has become more than just a buzzword; it's a fundamental principle that drives innovation and growth. Pharmaceutical manufacturing is no exception, with companies increasingly focusing on adopting circular economy practices to reduce waste, lower carbon emissions, and enhance resource efficiency.

In this blog, we will explore the concept of circular economy practices in pharmaceutical manufacturing, with a special focus on how integration between PlanetTogether and leading ERP, SCM, and MES systems, such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, can play a pivotal role in achieving sustainability goals.

Understanding the Circular Economy

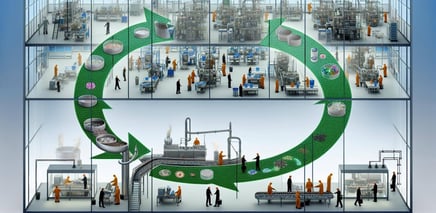

It's essential to grasp the concept of the circular economy. Unlike the traditional linear economy, which follows a "take, make, dispose" model, the circular economy emphasizes sustainability by designing products and processes that minimize waste and maximize the reuse, recycling, and recovery of materials. Pharmaceutical manufacturers can benefit immensely from embracing circular economy practices, given the industry's significant environmental footprint.

Key Circular Economy Practices in Pharmaceutical Manufacturing

Closed-Loop Supply Chains: Implementing closed-loop supply chains involves the collection and recycling of pharmaceutical packaging materials, such as glass bottles and plastic containers. These materials can be sanitized and reused, significantly reducing the need for virgin resources.

Sustainable Packaging: Reducing the environmental impact of packaging materials is crucial. Pharmaceutical companies can opt for eco-friendly packaging options, such as biodegradable or recyclable materials, to minimize waste.

Resource Efficiency: Optimizing resource use within manufacturing processes is a key circular economy practice. This includes reducing water consumption, energy usage, and raw material waste.

Extended Product Life: Designing pharmaceutical products for longer shelf lives can reduce the frequency of production, ultimately lowering waste generation and energy consumption.

Integration for Sustainable Transformation

Now, let's discuss how integrating advanced planning and scheduling solutions like PlanetTogether with ERP, SCM, and MES systems can facilitate the adoption of circular economy practices.

Seamless Data Flow: Integration ensures a seamless flow of data between different systems. For instance, PlanetTogether can communicate production schedules and resource requirements to ERP systems like SAP and Oracle in real-time. This helps in efficient resource allocation and minimizes excess inventory, reducing waste.

Demand Forecasting: By integrating with SCM systems, pharmaceutical manufacturers can improve demand forecasting accuracy. This leads to better inventory management, reducing overproduction and its associated environmental impact.

MES Integration: Manufacturing Execution Systems (MES) play a critical role in monitoring and controlling production processes. Integration with PlanetTogether allows for real-time tracking of resource utilization and waste generation, enabling quick adjustments to minimize environmental impact.

Traceability and Compliance: Integration with ERP systems helps in maintaining traceability throughout the supply chain. This is crucial for ensuring compliance with sustainability regulations and standards.

Challenges and Considerations

While integration can bring substantial benefits, it's essential to address some challenges and considerations:

Data Security: Protecting sensitive pharmaceutical data is paramount. Robust cybersecurity measures must be in place to safeguard information during integration.

Cost and Implementation Time: Integrating systems can be a substantial investment in terms of both time and money. Companies need to carefully assess the ROI and plan accordingly.

Change Management: Employees may need training to adapt to new integrated systems. Change management strategies should be implemented to ensure a smooth transition.

Circular economy practices are a critical part of the pharmaceutical industry's sustainability journey. Integrating advanced planning and scheduling solutions like PlanetTogether with ERP, SCM, and MES systems can be a game-changer in achieving sustainability goals.

As a Purchasing Manager in a pharmaceutical manufacturing facility, embracing these practices and exploring integration possibilities can lead to reduced waste, lower carbon emissions, and enhanced resource efficiency, ultimately contributing to a greener and more sustainable future for the industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the pharmaceutical industry.