Building Resilient Supply Chain Strategies: Navigating Global Disruptions

In the interconnected world, supply chain managers in the food and beverage manufacturing industry face unprecedented challenges. From natural disasters to geopolitical tensions, the global landscape is rife with disruptions that can wreak havoc on supply chains.

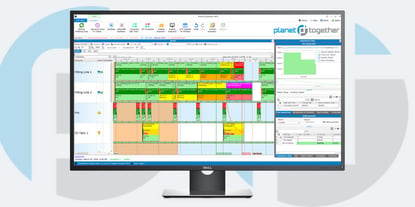

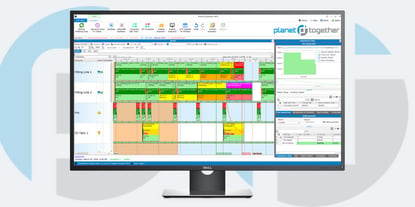

In this blog, we will explore resilient supply chain strategies tailored to the unique needs of food and beverage manufacturers, with a focus on integrating advanced planning and scheduling solutions like PlanetTogether with leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and others.

Challenges Facing Supply Chain Managers

Before looking into solutions, it's crucial to understand the challenges facing supply chain managers in the food and beverage industry. These challenges include:

Demand Volatility: Consumer preferences are constantly changing, leading to fluctuations in demand for various products.

Supply Chain Complexity: Food and beverage supply chains are often complex, involving multiple suppliers, distributors, and retailers.

Compliance and Regulations: Stringent regulations govern the production and distribution of food and beverages, adding an extra layer of complexity.

Quality Control: Maintaining high-quality standards throughout the supply chain is paramount to ensuring consumer safety and satisfaction.

Global Disruptions: Natural disasters, geopolitical conflicts, and pandemics can disrupt supply chains on a global scale, leading to shortages and delays.

Integration between PlanetTogether and ERP, SCM, and MES Systems

To address these challenges, supply chain managers must adopt resilient strategies that enable them to anticipate, adapt to, and recover from disruptions effectively. Here are some key strategies:

End-to-End Visibility: Achieving real-time visibility across the entire supply chain is essential for identifying potential disruptions early and implementing proactive measures. Integration between advanced planning and scheduling solutions like PlanetTogether and ERP, SCM, and MES systems facilitates seamless data flow and enables comprehensive visibility into inventory levels, production schedules, and logistics.

Demand Forecasting and Planning: Leveraging advanced analytics and machine learning algorithms, supply chain managers can improve demand forecasting accuracy and anticipate shifts in consumer demand more effectively. By integrating PlanetTogether with ERP systems like SAP or Oracle, companies can align production schedules with demand forecasts in real-time, minimizing the risk of overstocking or stockouts.

Supplier Collaboration: Building strong relationships with suppliers and fostering collaboration is crucial for ensuring a resilient supply chain. By integrating SCM systems like Kinaxis or Aveva with PlanetTogether, companies can streamline communication with suppliers, share critical information, and coordinate production schedules more efficiently.

Agility and Flexibility: In today's dynamic business environment, agility and flexibility are essential qualities of a resilient supply chain. By implementing advanced planning and scheduling solutions like PlanetTogether, companies can quickly adjust production schedules in response to changing market conditions, supplier disruptions, or unforeseen events.

Risk Management: Identifying and mitigating potential risks is a fundamental aspect of supply chain resilience. By integrating risk management tools with ERP and SCM systems, companies can assess the impact of various risks on their supply chain and develop contingency plans to minimize disruptions.

As global disruptions continue to reshape the landscape of food and beverage manufacturing, supply chain resilience emerges as a critical differentiator between success and stagnation.

Building a resilient supply chain is imperative for food and beverage manufacturers to thrive in today's volatile business environment. By adopting advanced planning and scheduling solutions like PlanetTogether and integrating them with leading ERP, SCM, and MES systems, companies can enhance visibility, agility, and collaboration across the supply chain, enabling them to anticipate, adapt to, and recover from disruptions more effectively.

Embracing these strategies will not only improve operational efficiency but also strengthen customer satisfaction and brand reputation in the long run. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT