Building Resilient Schedules Using AI-Driven Scenarios in Medical Manufacturing

From ensuring compliance with stringent regulations to managing complex supply chains and meeting dynamic market demands, the need for a robust scheduling approach has never been more critical in medical manufacturing. Enter AI-driven scenarios—a transformative solution that enhances production planning and builds resilient schedules tailored to the unique requirements of medical manufacturing.

The Case for Resilience in Scheduling

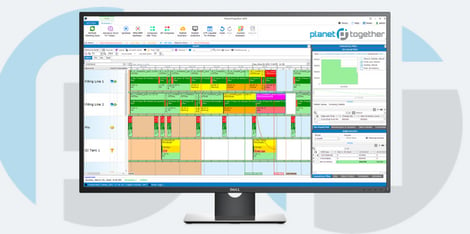

Resilience in production scheduling refers to the ability to adapt swiftly to disruptions while maintaining operational efficiency. In medical manufacturing, where disruptions can have dire consequences on patient health and safety, this resilience is non-negotiable. The integration of advanced tools like PlanetTogether with enterprise systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva unlocks new possibilities for building schedules that are both robust and flexible.

Challenges in Medical Manufacturing Scheduling

Regulatory Compliance: Adhering to stringent guidelines from regulatory bodies like the FDA or EMA demands meticulous planning.

Demand Volatility: The unpredictable nature of demand, often driven by pandemics, recalls, or innovations, complicates planning.

Resource Constraints: Limited availability of skilled labor, specialized equipment, and critical raw materials.

Supply Chain Disruptions: Delays, shortages, and geopolitical factors affecting supply chain stability.

High Stakes: Errors in scheduling can result in non-compliance, delayed product launches, and, ultimately, risks to patient lives.

How AI-Driven Scenarios Transform Scheduling

AI-driven scenarios leverage advanced algorithms and data analytics to simulate, analyze, and optimize production schedules. This proactive approach empowers production planners to anticipate disruptions, evaluate alternatives, and implement the best course of action.

Key Benefits of AI-Driven Scenarios

Enhanced Forecasting Accuracy: By analyzing historical data and real-time inputs, AI enables precise demand forecasting.

Dynamic Adaptability: Scenarios can be adjusted quickly to reflect changes in demand, supply, or production capacity.

Risk Mitigation: Simulating various scenarios allows planners to identify potential risks and develop contingency plans.

Improved Resource Utilization: AI optimizes the allocation of resources, reducing waste and increasing efficiency.

Regulatory Compliance: Automated tracking and reporting streamline compliance with industry standards.

The Role of Integration in Achieving Resilience

The integration of PlanetTogether with leading enterprise systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva is pivotal in realizing the full potential of AI-driven scenarios. Here’s how:

Seamless Data Flow

Integrated systems ensure real-time synchronization of data across production, inventory, procurement, and quality management functions. For example, integrating PlanetTogether with SAP enables a unified view of production schedules and supply chain data, facilitating informed decision-making.

Advanced Analytics

By combining the powerful analytical capabilities of PlanetTogether with the advanced reporting tools of systems like Microsoft Dynamics or Oracle, production planners gain actionable insights. These insights are instrumental in evaluating scenario outcomes and optimizing schedules.

Enhanced Collaboration

Integration fosters cross-departmental collaboration by breaking down silos. Tools like Kinaxis facilitate concurrent planning, enabling stakeholders from production, supply chain, and quality assurance to work cohesively.

Scalable Solutions

As medical manufacturers scale operations, integrated platforms like Aveva and PlanetTogether ensure that scheduling systems remain efficient and robust, adapting seamlessly to increased complexity.

Building a Resilient Future

For production planners in medical manufacturing, the journey toward resilient scheduling begins with embracing AI-driven scenarios and leveraging integration. Here are actionable steps to get started:

Evaluate Current Systems: Assess the existing scheduling tools and their integration capabilities with enterprise systems.

Adopt Advanced Tools: Invest in solutions like PlanetTogether and explore their integration with SAP, Oracle, Microsoft, Kinaxis, or Aveva.

Leverage Data: Utilize historical and real-time data to train AI algorithms for accurate forecasting and scenario planning.

Foster Collaboration: Ensure cross-functional teams are aligned and equipped to use integrated platforms effectively.

Continuously Improve: Monitor performance, gather feedback, and refine scheduling processes to enhance resilience.

In medical manufacturing, resilient scheduling is a strategic imperative. AI-driven scenarios, supported by the seamless integration of PlanetTogether with enterprise systems, empower production planners to navigate complexities with confidence. By investing in these advanced tools and processes, medical manufacturers can not only ensure operational efficiency but also safeguard the health and well-being of patients worldwide.

The time to build resilience is now. With AI-driven scenarios and integrated platforms, production planners have the power to transform challenges into opportunities and lead their organizations into a future defined by innovation and excellence.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Advanced Analytics, PlanetTogether Software, Integrating PlanetTogether, Seamless Data Flow, Enhanced Collaboration, Scalable Solutions, Medical Manufacturing

LEAVE A COMMENT