Hybrid Intelligent Systems for Production Planning

The role of a Production Scheduler has become increasingly complex in the Food and Beverage industry. The demand for agility, efficiency, and precision in production planning has led to the adoption of advanced technologies. Among these, hybrid intelligent systems have emerged as a game-changer, seamlessly integrating with Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES).

This blog will explore the transformative power of hybrid intelligent systems, with a focus on their integration with PlanetTogether and leading ERP systems such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and others.

Challenges Faced by Production Schedulers

Before looking into the specifics, let's take a moment to understand the challenges faced by Production Schedulers in the Food and Beverage manufacturing sector. Fluctuating market demands, seasonal variations, ingredient availability, and compliance with stringent regulations are just a few of the hurdles that demand a dynamic and adaptive approach to production planning.

Traditional production planning methods often fall short in addressing these challenges, leading to inefficiencies, increased costs, and suboptimal resource utilization. This is where the integration of hybrid intelligent systems becomes pivotal.

Hybrid Intelligent Systems: A Synergistic Approach

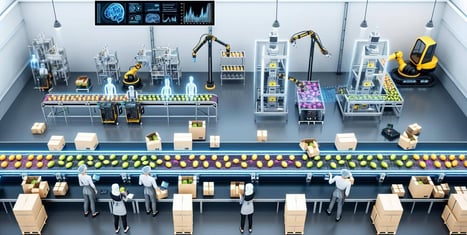

Hybrid intelligent systems combine the strengths of artificial intelligence, machine learning, and optimization algorithms to create a synergistic approach to production planning. These systems leverage historical data, real-time information, and predictive analytics to make informed decisions, allowing Production Schedulers to navigate the intricate web of variables with confidence.

![]()

Integration with PlanetTogether

PlanetTogether, a leading advanced planning and scheduling (APS) solution, acts as the linchpin in this transformative journey. Its robust capabilities in production scheduling, capacity planning, and scenario analysis set the stage for a seamless integration with ERP, SCM, and MES systems.

SAP Integration: A Unified Ecosystem

SAP, a global leader in ERP solutions, provides a comprehensive suite of tools for managing various business processes. When integrated with PlanetTogether, the production scheduler gains access to real-time data synchronization, enabling a unified ecosystem. The seamless flow of information between SAP and PlanetTogether facilitates better decision-making and ensures that production plans align with broader business objectives.

Oracle Fusion: Optimizing End-to-End Processes

Oracle's Fusion ERP brings a holistic approach to production planning. Integration with PlanetTogether extends this capability by optimizing end-to-end processes. From demand forecasting to inventory management, the combined power of Oracle Fusion and PlanetTogether allows Production Schedulers to create agile and adaptive production plans that respond in real-time to market changes.

Microsoft Dynamics 365: Agility in Action

Microsoft Dynamics 365, with its modular approach to ERP, offers flexibility and scalability. When paired with PlanetTogether, this integration empowers Production Schedulers with agility in action. The real-time synchronization between Microsoft Dynamics 365 and PlanetTogether ensures that any changes in the production environment are reflected instantaneously, fostering a proactive and responsive production planning process.

Kinaxis RapidResponse: Orchestrating Responsiveness

Kinaxis RapidResponse excels in providing supply chain visibility and response management. Integrating with PlanetTogether creates a dynamic duo that orchestrates responsiveness in production planning. The combination allows Production Schedulers to anticipate disruptions, assess their impact, and quickly devise alternative plans, ensuring that production stays on course even in the face of unforeseen challenges.

Aveva: Bridging the Gap between Planning and Execution

Aveva's MES solutions are renowned for bridging the gap between planning and execution. When integrated with PlanetTogether, this synergy ensures that the production plan seamlessly translates into actionable tasks on the shop floor. Real-time communication between Aveva and PlanetTogether optimizes production schedules, enhances resource utilization, and minimizes delays in execution.

Benefits of Hybrid Intelligent Systems Integration

Enhanced Decision-Making

The integration of hybrid intelligent systems with ERP, SCM, and MES systems enhances the decision-making process for Production Schedulers. Real-time data, predictive analytics, and optimization algorithms empower schedulers to make informed and strategic decisions that align with broader business goals.

Agility in Production Planning

The dynamic nature of the Food and Beverage industry requires a production planning process that can adapt to changes swiftly. Hybrid intelligent systems, when integrated seamlessly with ERP and other systems, enable Production Schedulers to create agile and responsive plans that can be adjusted in real-time to meet evolving market demands.

Optimized Resource Utilization

By leveraging historical data and predictive analytics, hybrid intelligent systems assist in optimizing resource utilization. This includes efficient allocation of manpower, machinery, and raw materials, leading to cost savings and improved overall efficiency.

End-to-End Visibility

Integration with ERP, SCM, and MES systems provides Production Schedulers with end-to-end visibility into the entire production process. This visibility allows for proactive problem-solving, early detection of bottlenecks, and a comprehensive understanding of how production plans align with organizational objectives.

Improved Compliance and Traceability

In the Food and Beverage industry, compliance with regulations and traceability are paramount. The integration of hybrid intelligent systems ensures that production plans adhere to regulatory requirements, and detailed traceability is maintained throughout the manufacturing process.

Reduced Lead Times and Inventory Costs

The optimization capabilities of hybrid intelligent systems contribute to the reduction of lead times and inventory costs. By synchronizing with ERP and SCM systems, these systems help in creating production plans that minimize excess inventory and respond efficiently to changes in demand.

The adoption of hybrid intelligent systems for production planning in Food and Beverage manufacturing is a strategic imperative for staying competitive in a dynamic market. The integration of these systems with leading ERP, SCM, and MES solutions such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and others brings unparalleled advantages to Production Schedulers.

By harnessing the power of real-time data, predictive analytics, and optimization algorithms, hybrid intelligent systems pave the way for a new era of efficiency, agility, and precision in production planning.

As the industry continues to evolve, embracing these transformative technologies will be the key to unlocking a future where production planning is not just a process but a strategic advantage.

Topics: PlanetTogether Software, Integrating PlanetTogether, Improved Compliance and Traceability, End-to-End Visibility, Enhanced Decision-Making Capabilities, Reduced Lead Times and Inventory Costs, Optimized Resource Utilization, Agility in Production Planning

LEAVE A COMMENT