Bridging Supply Chain Management Gaps with AI and PlanetTogether Integrations

Efficient Supply Chain Management (SCM) is not just an operational necessity but a strategic advantage. The challenges of ensuring compliance, meeting demand variability, and minimizing waste make it imperative for Operations Directors to explore innovative solutions.

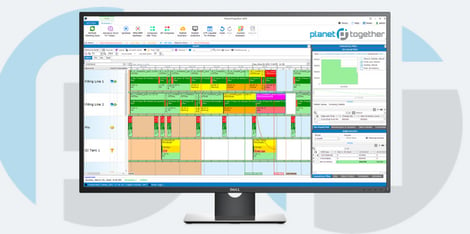

One such game-changer is the integration of PlanetTogether Advanced Planning and Scheduling (APS) software with enterprise systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva. Augmented by Artificial Intelligence (AI), this integration bridges critical gaps in SCM, driving operational excellence and enhancing competitiveness.

The Complexities of SCM in Medical Manufacturing

Medical manufacturing operates under stringent regulations and demands precise coordination across the supply chain. Delays, material shortages, or inefficiencies not only increase costs but can also impact patient outcomes. Key challenges include:

Demand Variability: Fluctuations in demand for medical devices or pharmaceuticals due to pandemics or seasonal trends.

Regulatory Compliance: Adhering to FDA, ISO, and other international standards.

Inventory Management: Balancing inventory levels to avoid stockouts or overstocking.

Production Scheduling: Ensuring optimal utilization of assets while meeting tight deadlines.

Traditional SCM systems often fall short of addressing these challenges comprehensively. This is where AI-powered tools and advanced integrations come into play.

The Role of AI in Transforming SCM

AI brings predictive and prescriptive capabilities to SCM, enabling proactive decision-making. By analyzing historical data and real-time inputs, AI can identify patterns, predict disruptions, and recommend optimal actions. Key AI-driven benefits include:

Predictive Analytics: Anticipating demand changes or potential disruptions.

Enhanced Visibility: Providing a unified view of the supply chain, from procurement to delivery.

Dynamic Optimization: Continuously adjusting schedules and resources to align with changing priorities.

When integrated with PlanetTogether and systems like SAP or Oracle, AI’s potential is fully realized, enabling a seamless flow of actionable insights across the enterprise.

PlanetTogether Integrations: A Catalyst for SCM Efficiency

PlanetTogether’s APS software enhances planning and scheduling capabilities by providing real-time visibility, scenario planning, and optimization tools. When coupled with leading ERP and SCM systems, the synergy is transformative:

Integration with SAP

SAP’s ERP and SCM modules are widely used for managing complex manufacturing operations. Integrating PlanetTogether with SAP allows for:

Automated Data Synchronization: Streamlining the flow of data between scheduling and inventory management.

Scenario Planning: Creating multiple scheduling scenarios to address demand changes without disrupting the supply chain.

Improved Compliance: Ensuring production schedules align with quality control and regulatory requirements.

Integration with Oracle

Oracle’s SCM solutions, known for their robustness, benefit significantly from PlanetTogether’s advanced scheduling capabilities:

Resource Optimization: Aligning Oracle’s resource management tools with PlanetTogether’s scheduling engine to maximize asset utilization.

Real-Time Monitoring: Leveraging Oracle’s IoT and AI modules to feed real-time data into PlanetTogether, enhancing responsiveness.

Enhanced Collaboration: Enabling cross-functional teams to access synchronized schedules and inventory data.

Integration with Microsoft Dynamics

Microsoft Dynamics 365’s modular ERP and CRM capabilities complement PlanetTogether in several ways:

Intelligent Workflows: Using Dynamics’ AI-driven insights to refine scheduling algorithms in PlanetTogether.

Scalable Operations: Supporting multi-site operations with unified planning and scheduling.

User-Friendly Interfaces: Leveraging Microsoft’s familiar interface to enhance user adoption and efficiency.

Integration with Kinaxis

Kinaxis’ RapidResponse platform is renowned for its supply chain planning capabilities. When paired with PlanetTogether:

Concurrent Planning: Synchronizing supply chain and production schedules in real time.

Risk Mitigation: Using Kinaxis’ simulation tools to predict the impact of schedule changes on the supply chain.

Faster Response Times: Enabling quick adjustments to disruptions or demand shifts.

Integration with Aveva

Aveva’s focus on industrial software solutions makes it a strong partner for PlanetTogether:

Digital Twin Capabilities: Incorporating Aveva’s digital twin insights into scheduling to improve asset performance.

Sustainability Goals: Aligning scheduling decisions with energy efficiency and waste reduction targets.

Enhanced Visualization: Using Aveva’s advanced visualization tools to present scheduling and supply chain data comprehensively.

Addressing SCM Gaps with AI-Driven PlanetTogether Integrations

The integration of PlanetTogether with these enterprise systems, powered by AI, addresses several critical SCM gaps in medical manufacturing:

Demand Planning and Forecasting

AI models can analyze vast datasets, including historical sales, market trends, and seasonal factors, to predict demand more accurately. This data is seamlessly shared with PlanetTogether, ensuring schedules are aligned with anticipated needs.

Inventory Optimization

With real-time inventory data from SAP or Oracle, PlanetTogether can adjust schedules dynamically to prevent stockouts or overproduction. AI further enhances this by identifying optimal reorder points and inventory levels.

Production Flexibility

Medical manufacturing often requires rapid shifts in production priorities. The integration allows Operations Directors to evaluate multiple scheduling scenarios in PlanetTogether, supported by Kinaxis’ concurrent planning capabilities or Aveva’s digital twin insights.

Regulatory Compliance

By connecting PlanetTogether with ERP systems like Microsoft Dynamics or Oracle, manufacturers can ensure that production schedules incorporate compliance checkpoints, reducing the risk of non-conformance.

Cost Management

AI-driven insights enable cost-efficient scheduling by identifying bottlenecks, minimizing idle times, and optimizing resource allocation. These recommendations flow directly into PlanetTogether, translating into actionable schedules.

Future Outlook: AI and Beyond

The integration of PlanetTogether with enterprise systems is just the beginning. Emerging technologies like blockchain for supply chain transparency, advanced robotics for production automation, and IoT for real-time asset tracking are set to further revolutionize SCM in medical manufacturing. Operations Directors who embrace these innovations will gain a significant competitive edge.

Bridging SCM gaps in medical manufacturing requires a strategic approach that combines advanced planning tools like PlanetTogether with the robust capabilities of SAP, Oracle, Microsoft, Kinaxis, or Aveva. When augmented by AI, these integrations transform SCM from a reactive process into a proactive, dynamic, and efficient system.

For Operations Directors, the message is clear: Investing in these technologies isn’t just about solving today’s challenges. It’s about building a resilient and agile supply chain that can adapt to tomorrow’s demands. The future of medical manufacturing depends on it.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the medical industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Reduction in Lead Times, Medical Manufacturing, Improved Compliance, Inventory Cost Savings

LEAVE A COMMENT