Predictive Scheduling

In the landscape of industrial manufacturing, where every minute counts and efficiency is essential, downtime is the enemy. Production planners face the daunting challenge of orchestrating complex operations while striving to minimize downtime and maximize productivity. Traditional scheduling methods often fall short in addressing the complexities and uncertainties inherent in manufacturing processes. However, the emergence of AI-driven predictive scheduling solutions offers a transformative approach to tackle this challenge head-on.

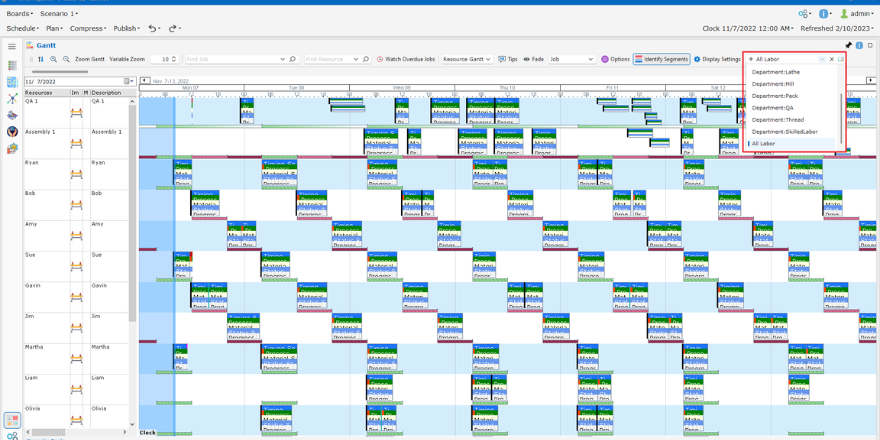

In this blog, we look into the significance of predictive scheduling in industrial manufacturing and explore how integrating advanced planning and scheduling (APS) systems like PlanetTogether with leading ERP, SCM, and MES platforms such as SAP, Oracle, Microsoft, Kinaxis, and Aveva can revolutionize production planning processes, paving the way for unprecedented efficiency and minimal downtime.

Understanding the Need for Predictive Scheduling

Downtime in manufacturing can result from various factors, including equipment breakdowns, material shortages, unexpected maintenance requirements, and suboptimal scheduling decisions. Each minute of downtime translates into lost production opportunities, increased costs, and compromised customer satisfaction. Therefore, production planners must adopt proactive strategies to anticipate and mitigate potential disruptions before they occur.

Predictive scheduling harnesses the power of AI and advanced algorithms to forecast future production scenarios based on historical data, real-time information, and predictive analytics. By analyzing patterns, identifying trends, and considering multiple variables, predictive scheduling enables production planners to anticipate potential bottlenecks, optimize resource allocation, and proactively adjust schedules to minimize downtime and maximize throughput.

Integration between PlanetTogether and ERP, SCM, and MES Systems

The seamless integration between predictive scheduling solutions like PlanetTogether and industry-leading ERP, SCM, and MES systems represents a paradigm shift in production planning and scheduling. By leveraging data exchange capabilities and interoperability between these platforms, organizations can unlock new levels of efficiency, agility, and responsiveness in their manufacturing operations.

SAP: Integrating PlanetTogether with SAP ERP empowers production planners with real-time visibility into inventory levels, production orders, and resource availability. By synchronizing data between the two systems, organizations can streamline the scheduling process, optimize production sequences, and align production plans with business objectives.

Furthermore, leveraging SAP's advanced analytics capabilities enhances the accuracy of predictive models, enabling more informed decision-making and proactive risk management.

Oracle: The integration of PlanetTogether with Oracle SCM enables end-to-end visibility and control over supply chain operations, from raw material procurement to finished goods distribution. By synchronizing production schedules with demand forecasts, inventory levels, and supplier lead times, organizations can dynamically adjust production plans to minimize disruptions and optimize inventory holding costs.

Additionally, leveraging Oracle's cloud-based infrastructure enhances scalability, flexibility, and accessibility, allowing production planners to collaborate seamlessly across geographical locations and organizational boundaries.

Microsoft: Microsoft Dynamics 365 offers a comprehensive suite of ERP and CRM solutions designed to streamline business processes, enhance customer engagement, and drive digital transformation. By integrating PlanetTogether with Microsoft Dynamics, organizations can unify production planning, scheduling, and execution within a single, cohesive ecosystem. The seamless flow of data between the two systems facilitates real-time decision-making, enhances cross-functional collaboration, and accelerates time-to-market for new products.

Furthermore, leveraging Microsoft's Power Platform empowers production planners to build custom dashboards, reports, and analytics tools tailored to their specific needs, enabling continuous improvement and innovation in scheduling processes.

Kinaxis: Kinaxis RapidResponse is a cloud-based supply chain planning platform that enables organizations to orchestrate end-to-end supply chain processes in real time. By integrating PlanetTogether with Kinaxis RapidResponse, organizations can achieve synchronized planning across all functions and levels of the supply chain, from demand planning to production scheduling to inventory optimization.

The seamless exchange of data between the two systems facilitates agile decision-making, scenario analysis, and risk mitigation, enabling organizations to adapt quickly to changing market conditions and customer demands.

Aveva: Aveva's comprehensive portfolio of industrial software solutions encompasses everything from process simulation and design to asset performance management and production optimization. By integrating PlanetTogether with Aveva's manufacturing execution system (MES), organizations can bridge the gap between production planning and execution, ensuring seamless coordination and alignment between the two domains.

The integration enables real-time visibility into production progress, quality metrics, and resource utilization, empowering production planners to make data-driven decisions and respond swiftly to evolving production requirements.

Benefits of AI-Driven Predictive Scheduling

The integration of predictive scheduling solutions with ERP, SCM, and MES systems offers a multitude of benefits for industrial manufacturing organizations:

Minimized Downtime:

By leveraging AI-driven predictive models to anticipate potential bottlenecks and proactively adjust production schedules, organizations can minimize downtime, maximize equipment utilization, and optimize resource allocation.

Enhanced Efficiency:

Predictive scheduling enables production planners to optimize production sequences, minimize changeover times, and synchronize production plans with demand forecasts, resulting in improved operational efficiency and reduced lead times.

Improved Decision-Making:

By providing real-time visibility into production status, resource availability, and demand fluctuations, predictive scheduling empowers production planners to make informed decisions, prioritize tasks, and allocate resources effectively, thereby enhancing overall productivity and performance.

Increased Agility:

The ability to simulate "what-if" scenarios, evaluate alternative production strategies, and respond quickly to changing market dynamics enhances organizational agility and resilience, enabling organizations to adapt swiftly to unforeseen disruptions and seize new opportunities.

Enhanced Collaboration:

By integrating predictive scheduling solutions with ERP, SCM, and MES systems, organizations can break down silos, foster cross-functional collaboration, and facilitate seamless communication and information sharing across departments and functions, driving alignment and synergy across the entire value chain.

In the era of Industry 4.0, where data-driven decision-making and digital transformation are reshaping the industrial landscape, predictive scheduling emerges as a game-changing technology that holds the key to unlocking new levels of efficiency, agility, and competitiveness in manufacturing operations.

By integrating advanced planning and scheduling solutions like PlanetTogether with leading ERP, SCM, and MES platforms, organizations can harness the power of AI-driven predictive analytics to minimize downtime, optimize resource utilization, and drive continuous improvement across the entire production lifecycle.

Embracing predictive scheduling is not just about optimizing schedules; it's about transforming the way we think about production planning and unleashing the full potential of industrial manufacturing in the digital age.

Topics: Industrial Manufacturing, PlanetTogether Software, Integrating PlanetTogether, Enhanced Collaboration, Minimized Downtime and Improved Efficiency, Improved Decision-Making and Agility, End-to-End Visibility into Supply Chain

LEAVE A COMMENT