AI-driven Automation for Profitability

Profitability hinges not only on the quality of products and regulatory compliance but increasingly on the efficiency and adaptability of manufacturing processes. For Manufacturing IT Managers, the ongoing pursuit of operational excellence calls for solutions that streamline processes and optimize resources. The integration of AI-driven automation across systems like PlanetTogether and ERP solutions, such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, offers transformative potential in improving decision-making, reducing costs, and maximizing productivity.

This article will dive into how AI-driven automation can empower pharmaceutical facilities to achieve profitability while maintaining the high standards of quality and compliance expected in the industry. We'll examine specific applications and how integrated platforms like PlanetTogether and ERP systems create synergies to enhance productivity and support sustainable profit margins.

Understanding AI-driven Automation in Pharmaceutical Manufacturing

AI-driven automation represents the fusion of artificial intelligence with automation technologies to handle repetitive, data-intensive tasks and deliver actionable insights. For the pharmaceutical industry, where precision and accuracy are paramount, AI provides the ability to not only expedite processes but also enhance them. It is the cornerstone of creating a "smart factory," where decisions can be data-driven, minimizing the manual intervention that can lead to bottlenecks and errors.

Some key benefits of AI-driven automation in the pharmaceutical sector include:

Reduced Production Costs: Automation reduces labor costs and minimizes human errors, leading to fewer reworks and lower overheads.

Increased Throughput: AI-driven planning and scheduling reduce idle time and optimize resource allocation, allowing for higher throughput.

Enhanced Quality Control: Machine learning algorithms analyze vast datasets to predict and correct quality issues before they escalate, ensuring consistency and adherence to regulatory standards.

ERP and APS Integration for Holistic Automation

An Enterprise Resource Planning (ERP) system, such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, serves as the backbone of pharmaceutical manufacturing operations by centralizing data and processes. However, when integrated with an Advanced Planning and Scheduling (APS) system like PlanetTogether, it empowers IT Managers to orchestrate automation across the entire manufacturing lifecycle.

How Integration Enhances Automation

Seamless Data Flow: Integration allows real-time data exchange between the ERP and APS systems, ensuring that production schedules, inventory levels, and maintenance alerts are up-to-date and accurate.

Optimized Resource Allocation: By syncing with ERP data on resource availability, PlanetTogether can leverage AI algorithms to optimize scheduling, minimizing downtime and reducing costly machine changeovers.

Enhanced Demand Forecasting: AI-driven insights from ERP and APS integration enable more accurate demand forecasting, allowing manufacturing schedules to align with real market needs, preventing both stockouts and overproduction.

Through AI-driven automation, IT Managers can facilitate an environment where these integrated systems work in unison, significantly contributing to the profitability of pharmaceutical operations.

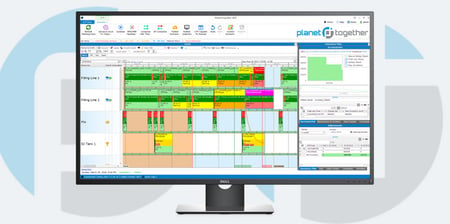

![]()

Key AI-driven Automation Applications in Pharmaceutical Manufacturing

Intelligent Scheduling and Resource Optimization

In pharmaceutical manufacturing, production schedules are often disrupted by unexpected events such as equipment malfunctions, supply chain delays, or last-minute changes in demand. PlanetTogether’s AI-driven capabilities, integrated with ERP platforms, enable intelligent scheduling that dynamically adapts to such disruptions.

For instance, if an ERP system flags an issue with inventory levels or alerts on an upcoming maintenance window, PlanetTogether can automatically adjust production schedules to accommodate these changes. The AI-driven algorithms consider a myriad of factors — such as production timelines, resource availability, and order priorities — to create optimized schedules that maximize throughput while avoiding unnecessary costs.

Example:

Consider a scenario where demand for a particular pharmaceutical product spikes unexpectedly. An integrated PlanetTogether and ERP solution can analyze inventory levels, machine availability, and workforce shifts to adjust schedules on the fly, ensuring that the increased demand is met without overextending resources or incurring additional costs.

Predictive Maintenance for Reducing Downtime

Predictive maintenance leverages AI to monitor equipment conditions and predict when maintenance should be conducted to prevent unplanned breakdowns. For a pharmaceutical IT Manager, the integration of ERP data with PlanetTogether’s predictive maintenance capabilities allows for proactive equipment management, leading to fewer production delays and a direct improvement in profitability.

By analyzing historical maintenance data from the ERP system alongside real-time production data, AI can detect patterns that indicate potential failures. This enables facilities to perform maintenance activities only when necessary, avoiding unnecessary shutdowns while extending the lifespan of equipment.

Example:

If a particular machine in the production line has shown a tendency to wear down after a set number of cycles, AI algorithms can preemptively schedule maintenance during a low-production period. PlanetTogether, integrated with the ERP, ensures that the revised production schedule accommodates these maintenance windows without impacting delivery timelines.

Quality Assurance and Defect Reduction

In pharmaceutical manufacturing, quality is non-negotiable. Defects not only jeopardize product efficacy but can also lead to costly recalls and damaged reputation. Through machine learning algorithms, PlanetTogether integrated with ERP systems can improve quality assurance processes by identifying trends in production data that could lead to quality issues.

This automated quality control capability allows AI to spot inconsistencies in production processes or raw materials that might compromise product quality. The insights gained are then used to make immediate adjustments, whether that means recalibrating machinery or adjusting workflows, ultimately saving costs and ensuring product reliability.

Example:

Imagine that data analysis shows an uptick in deviations related to a specific production batch. PlanetTogether, integrated with an ERP system, can flag this anomaly in real time, allowing operators to investigate and adjust processes before the entire batch is compromised, reducing waste and ensuring quality standards are maintained.

Data-Driven Insights for Strategic Decision-Making

The data generated from integrated PlanetTogether and ERP platforms provides a wealth of insights for pharmaceutical manufacturers. With AI-driven analytics, IT Managers can leverage data to guide strategic decisions that enhance profitability.

Supply Chain Optimization

AI-driven insights from ERP and APS integration help IT Managers streamline supply chain operations, which is critical in a field where timing and precision are essential. By forecasting demand accurately and optimizing supplier relationships, facilities can reduce lead times, control costs, and minimize disruptions.

Product Lifecycle Management

From R&D to end-of-life, AI can analyze data to optimize every stage of a product's lifecycle. For example, it can identify trends that suggest the optimal time for scaling production or phasing out a product, ensuring that resources are allocated to the most profitable endeavors.

Performance Benchmarking and KPI Tracking

AI-driven analytics can track and benchmark Key Performance Indicators (KPIs) such as production efficiency, lead time, and defect rates. IT Managers can use these insights to continuously refine processes, set performance goals, and measure success, providing an agile approach to maintaining profitability.

Overcoming Challenges in Implementing AI-driven Automation

Implementing AI-driven automation in pharmaceutical manufacturing presents unique challenges, particularly around data security, regulatory compliance, and change management. However, with an integrated approach using platforms like PlanetTogether and ERP solutions, IT Managers can mitigate these challenges effectively.

Data Security and Privacy: Ensure that all systems are compliant with data privacy regulations and implement robust cybersecurity protocols to protect sensitive information.

Compliance and Validation: Pharmaceutical production systems must comply with strict regulatory standards. Working closely with PlanetTogether and ERP vendors to validate AI models ensures that automation solutions meet all compliance requirements.

Change Management: AI-driven automation represents a significant shift in traditional manufacturing workflows. Training staff, updating SOPs, and fostering a culture of data-driven decision-making can ease this transition.

AI-driven automation, powered by the integration of PlanetTogether and ERP platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, can substantially impact profitability in pharmaceutical manufacturing. By reducing production costs, optimizing resources, ensuring quality, and providing actionable insights, IT Managers can drive efficiencies that resonate across the entire organization.

In an industry that continually faces pressure to deliver high-quality products at controlled costs, the strategic application of AI-driven automation offers pharmaceutical facilities a competitive edge. As the manufacturing landscape continues to evolve, those who invest in integrated, AI-enhanced solutions will find themselves best positioned to not only maintain but also grow their profitability in an increasingly complex market.

Manufacturing IT Managers in the pharmaceutical sector have a unique opportunity to leverage AI-driven automation to build smarter, more resilient operations. Through the integration of PlanetTogether and ERP systems, they can ensure that every process, from production scheduling to quality control, is optimized for efficiency, setting the stage for sustainable, long-term profitability.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Supply Chain Optimization, PlanetTogether Software, Integrating PlanetTogether, Optimized Resource Allocation, Seamless Data Flow, Enhanced Demand Forecasting, Enhanced Product Lifecycle Management, Pharmaceutical Manufacturing, Predictive Maintenance for Reducing Downtime, Quality Assurance and Defect Reduction, Intelligent Scheduling and Resource Optimization, Performance Benchmarking and KPI Tracking

LEAVE A COMMENT