Scheduling with Multi-Agent Systems

The efficiency of production scheduling is vital in chemical manufacturing. With numerous variables at play, from raw material availability to equipment maintenance schedules, orchestrating the production process seamlessly can be daunting. However, with the advent of multi-agent systems (MAS), a new era of scheduling prowess has emerged.

In this blog, we look into the transformative potential of MAS for production schedulers in chemical manufacturing facilities. Moreover, we explore how integration between MAS platforms like PlanetTogether and leading ERP, SCM, and MES systems can elevate scheduling efficiency to unprecedented heights.

Understanding Multi-Agent Systems (MAS)

Multi-agent systems, a branch of artificial intelligence, simulate the interactions of multiple autonomous agents to achieve a specific goal. In the context of manufacturing scheduling, these agents can represent various elements of the production process, such as machines, materials, and tasks. Unlike traditional scheduling methods, MAS leverages decentralized decision-making, enabling adaptability and responsiveness to dynamic manufacturing environments.

Benefits of Multi-Agent Systems in Chemical Manufacturing

Adaptive Scheduling: MAS excels in dynamic environments by continuously evaluating and adjusting schedules in real-time. For chemical manufacturers dealing with volatile market demands and unforeseen disruptions, this adaptability is invaluable. MAS can swiftly accommodate changes in production priorities, resource availability, and unexpected events, minimizing downtime and maximizing throughput.

Optimization: By considering multiple factors simultaneously, MAS can optimize scheduling decisions to enhance efficiency and resource utilization. Through algorithms like genetic algorithms and reinforcement learning, MAS identifies optimal production sequences, reduces setup times, and balances workloads across machines. This optimization not only boosts productivity but also reduces energy consumption and production costs.

Collaborative Decision-Making: MAS fosters collaboration among production stakeholders, including schedulers, operators, and maintenance personnel. By enabling agents to communicate and negotiate autonomously, MAS facilitates consensus-building and conflict resolution in scheduling decisions. This collaborative approach promotes transparency, minimizes bottlenecks, and enhances overall operational efficiency.

Integration with ERP, SCM, and MES Systems

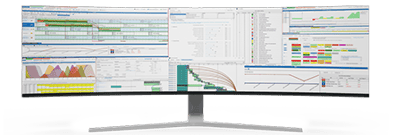

To realize the full potential of MAS in chemical manufacturing scheduling, seamless integration with enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES) is crucial. Platforms like PlanetTogether offer robust integration capabilities with leading ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, Aveva, and others.

This integration empowers production schedulers with comprehensive visibility and control over the entire manufacturing ecosystem, from order management to shop floor execution.

Key Integration Benefits Include:

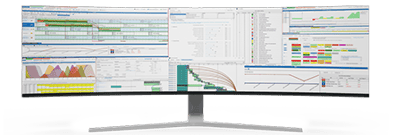

Real-Time Data Exchange: Integration between MAS and ERP/SCM/MES systems enables real-time data exchange, ensuring that scheduling decisions are based on accurate and up-to-date information. From inventory levels and order status to machine availability and production constraints, schedulers have access to the insights needed to make informed decisions swiftly.

Unified Planning Environment: By consolidating scheduling and planning activities within a unified environment, integration streamlines operations and eliminates silos. Schedulers can seamlessly transfer production plans between MAS and ERP/SCM/MES systems, ensuring consistency and alignment across the organization. This unified approach enhances coordination between departments, minimizes errors, and accelerates decision-making.

Enhanced Predictive Analytics: Leveraging data from ERP/SCM/MES systems, MAS can incorporate predictive analytics capabilities to anticipate future demand, identify potential risks, and proactively adjust schedules accordingly. By harnessing the power of machine learning and predictive modeling, production schedulers can optimize resource allocation, mitigate disruptions, and enhance overall resilience in the face of uncertainty.

-May-08-2024-04-36-12-8483-PM.png?width=300&height=48&name=logo%20(2)-May-08-2024-04-36-12-8483-PM.png)

Optimizing Chemical Production with PlanetTogether's MAS Platform Integration

Consider a chemical manufacturing facility that produces specialty chemicals for various industries. By integrating PlanetTogether's MAS platform with SAP's ERP system, the facility achieved remarkable improvements in scheduling efficiency and operational performance.

Real-Time Visibility: With seamless data exchange between PlanetTogether and SAP, schedulers gained real-time visibility into inventory levels, production orders, and customer demand. This enabled proactive scheduling adjustments to meet changing market dynamics and customer requirements.

Dynamic Optimization: Leveraging MAS capabilities, the facility optimized production schedules based on factors such as raw material availability, equipment constraints, and production priorities. As a result, downtime was minimized, and throughput increased, leading to significant cost savings and enhanced customer satisfaction.

Collaborative Decision-Making: Integration between PlanetTogether and SAP facilitated collaborative decision-making across departments, enabling alignment between production schedules and business objectives. Schedulers, operators, and managers could easily communicate and coordinate efforts to resolve conflicts and optimize resource utilization.

In chemical manufacturing scheduling, multi-agent systems represent a paradigm shift towards agility, optimization, and collaboration. By harnessing the power of PlanetTogether's MAS platform and integrating with leading ERP, SCM, and MES systems, production schedulers can elevate their capabilities to unprecedented levels.

From adaptive scheduling and optimization to collaborative decision-making and predictive analytics, PlanetTogether's MAS platform integration unlocks new opportunities for efficiency and innovation in chemical manufacturing operations.

Embracing MAS integration will be essential for staying ahead in an increasingly competitive landscape. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.