In the automotive parts and accessories sector, efficient production planning is crucial for success. Manufacturers in this industry face numerous challenges, including fluctuating demand, complex supply chains, and the need for rapid response to market changes. To address these challenges, many companies turn to advanced planning tools like PlanetTogether and integrate them with Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) solutions.

In this blog, we will explore the key aspects of advanced planning in the automotive parts and accessories sector and how the integration of PlanetTogether with ERP, SCM, and MES systems can drive operational excellence.

Challenges in the Automotive Parts and Accessories Sector

The automotive parts and accessories sector is known for its dynamic nature, which presents manufacturers with several challenges:

Fluctuating Demand:

Automotive manufacturers must cope with fluctuating demand due to market trends, seasonality, and economic factors. Accurate demand forecasting is essential to avoid overproduction or stockouts.

Complex Supply Chains:

The automotive supply chain involves a vast network of suppliers, manufacturers, and distributors. Managing this complexity efficiently is crucial to minimize lead times and costs.

Just-in-Time (JIT) Requirements:

Many automotive manufacturers rely on JIT production methods, which demand precise scheduling and inventory control to minimize waste and reduce carrying costs.

Customization and Variation:

The automotive parts sector often requires producing a wide range of SKUs with varying specifications, making production planning more intricate.

Global Competition:

Competing on a global scale means facing intense competition. Efficient planning can help reduce production costs and lead times, enhancing competitiveness.

Introduction to PlanetTogether

PlanetTogether is a powerful Advanced Planning and Scheduling (APS) software solution designed to help manufacturers optimize their production planning and scheduling processes. Its capabilities include:

Demand Forecasting:

Accurate demand forecasting to align production with actual market requirements.

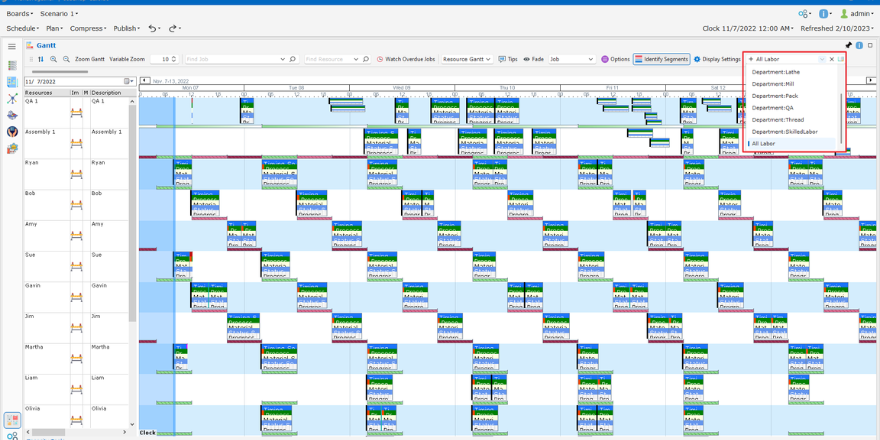

Constraint-Based Scheduling:

Generating production schedules that consider various constraints like machine capacity, labor, and materials.

Scenario Analysis:

Evaluating multiple "what-if" scenarios to make informed decisions.

Real-Time Visibility:

Providing real-time insights into production processes.

Integration Capabilities:

Seamless integration with ERP, SCM, and MES systems for comprehensive planning.

The Importance of Integration

Integrating PlanetTogether with your existing ERP, SCM, and MES systems can significantly enhance your production planning capabilities. Here's why integration matters:

Data Accuracy:

Integration ensures that all systems share accurate and up-to-date data, reducing errors and discrepancies.

Streamlined Processes:

Seamless data flow between systems streamlines planning, execution, and reporting processes.

Enhanced Visibility:

Integration provides end-to-end visibility, allowing you to track orders, inventory, and production in real-time.

Data-Driven Decision-Making:

Access to consolidated data empowers data-driven decision-making, which is crucial for efficient planning.

Automated Workflows:

Integration enables automation of routine tasks, freeing up planners to focus on strategic activities.

Integration with ERP Systems

ERP systems like SAP, Oracle, and Microsoft Dynamics are the backbone of many manufacturing operations. Integrating PlanetTogether with ERP systems offers several benefits:

Unified Data:

All relevant data, from sales orders to inventory levels, is consolidated within a single system.

Seamless Order Processing:

Orders flow seamlessly from ERP to PlanetTogether for production planning.

Improved Forecasting:

ERP data enhances demand forecasting accuracy.

Efficient Resource Allocation:

Real-time ERP data helps in optimizing resource allocation.

Enhanced Reporting:

Integration allows for comprehensive reporting capabilities, aiding decision-makers.

Integration with SCM Systems

Supply Chain Management systems play a crucial role in coordinating the movement of materials and products. Integrating PlanetTogether with SCM systems, such as Kinaxis, provides:

End-to-End Visibility:

A complete view of the supply chain, enabling proactive response to disruptions.

Optimized Inventory:

Improved inventory management with synchronized demand and supply data.

Collaborative Planning:

Better collaboration with suppliers and distributors, enhancing supply chain resilience.

Transportation Optimization:

Enhanced route planning and load optimization for cost-effective logistics.

Risk Mitigation:

Early identification and mitigation of supply chain risks.

Integration with MES Systems

Manufacturing Execution Systems (MES) are essential for shop floor control. Integrating PlanetTogether with MES systems, such as Aveva, offers:

Real-Time Data Exchange:

MES data provides real-time feedback on production progress.

Quality Control:

Integration ensures that quality control processes align with production schedules.

Resource Efficiency:

MES data aids in resource allocation, improving equipment utilization.

Traceability:

Complete traceability of materials and processes for compliance and quality assurance.

Reduced Downtime:

Integration enables predictive maintenance and minimizes unplanned downtime.

Implementation Best Practices

Successfully integrating PlanetTogether with ERP, SCM, and MES systems requires careful planning and execution. Some best practices include:

Define Clear Objectives:

Identify specific goals and KPIs for integration to measure success.

Engage Stakeholders:

Involve key stakeholders from IT, production, and management early in the process.

Data Cleansing:

Ensure data quality and consistency across all systems.

Testing and Validation:

Rigorously test the integration to identify and resolve any issues.

Training and Support:

Provide adequate training and ongoing support for users.

In the automotive parts and accessories sector, advanced planning is a competitive advantage. Integrating PlanetTogether with ERP, SCM, and MES systems empowers manufacturers to meet market demands efficiently, reduce costs, and improve overall operational excellence. With the right strategy and best practices, your company can thrive in this dynamic industry.

As a production planner, embracing these advanced planning techniques and technologies is not just an option; it's a necessity in today's rapidly evolving industrial landscape.

Topics: Data Accuracy, PlanetTogether Software, Integrating PlanetTogether, Data-Driven Decision-Making, Enhanced Visibility, Automated Workflows and Alerts, Streamlined Processes

LEAVE A COMMENT