Adopting Emerging Technologies: A Strategic Path

Emerging technologies are reshaping the way organizations operate, improving efficiency, reducing costs, and enhancing decision-making. As a Manufacturing IT Manager, you stand at the forefront of integrating these advancements, ensuring the technology stack aligns with both operational and strategic goals. Key technologies like artificial intelligence (AI), machine learning (ML), predictive analytics, and advanced scheduling tools such as PlanetTogether are essential to maintaining competitive edge.

However, their full potential is unlocked when combined with robust Enterprise Resource Planning (ERP) systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva.

This blog explores the strategic integration of these emerging technologies into industrial manufacturing environments and the best practices for deploying them alongside existing systems for maximum benefit.

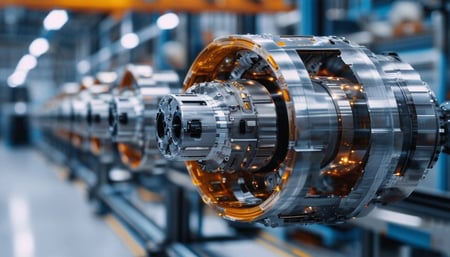

The Landscape of Emerging Technologies in Manufacturing

Emerging technologies are transforming industrial manufacturing in various ways, including:

Automation: Streamlining repetitive tasks, reducing errors, and optimizing production processes.

Predictive Maintenance: Leveraging data analytics to predict equipment failures before they happen, minimizing downtime.

AI and ML: Enhancing decision-making through insights derived from large datasets.

IoT and IIoT: Enabling interconnectedness of machines and systems, facilitating real-time data flow and control.

Advanced Scheduling Software: PlanetTogether, for example, optimizes production schedules based on available resources and demands, integrating seamlessly with ERP systems.

For IT managers, these technologies require careful planning, resources, and a strong understanding of how these tools can fit into existing infrastructure.

![]()

Integration of PlanetTogether with ERP Systems

As a specialized software for Advanced Planning and Scheduling (APS), PlanetTogether can play a critical role in improving operational efficiency. When integrated with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, the combined capabilities can drive transformative results in terms of visibility, control, and responsiveness within the production environment.

Key Benefits of Integration

Enhanced Visibility: ERP systems manage large volumes of data, including inventory, production orders, and work schedules. By connecting PlanetTogether, IT managers can provide real-time visibility into schedules and adjust production plans as needed based on current operational data.

Streamlined Workflow: Integrated APS and ERP systems can bridge information gaps, reducing manual data entry and ensuring consistent, accurate data across systems.

Responsive Manufacturing: With both APS and ERP data aligned, manufacturers can respond more effectively to demand shifts, reducing overproduction and stockouts.

Improved Decision-Making: The synchronization of real-time data from PlanetTogether with ERP systems allows IT managers to support data-driven decision-making processes, resulting in improved performance metrics across departments.

Addressing Integration Challenges

Integrating emerging technologies like PlanetTogether with established ERP platforms can present challenges, including:

Data Silos: Misaligned data structures or incomplete data flows between APS and ERP systems can cause silos, leading to inefficient workflows.

Legacy Systems Compatibility: Older systems may lack compatibility with newer technologies, requiring middleware or custom interfaces to facilitate smooth integration.

Change Management: Employees need time and training to adapt to new technology, especially when legacy practices are deeply embedded in the organization’s culture.

Cybersecurity Risks: The more interconnected the systems, the higher the risk of potential cyber vulnerabilities. Prioritizing data protection and monitoring protocols is crucial.

Best Practice for Overcoming Challenges

Data Mapping: Conduct a comprehensive mapping exercise to align data formats and ensure seamless data transfer between PlanetTogether and your ERP.

Middleware Solutions: When needed, consider middleware platforms that facilitate connectivity between disparate systems, preserving the ERP’s data integrity.

Training and Support: Regular training sessions and establishing IT support teams to guide employees through the transition can reduce resistance to change.

Enhanced Security Measures: Implement multi-layered security protocols and real-time monitoring to secure data.

Leveraging AI and ML for Predictive Analytics and Maintenance

AI and ML technologies can add a powerful dimension to your manufacturing IT strategy. By applying these technologies to data aggregated from both ERP systems and APS like PlanetTogether, Manufacturing IT Managers can gain insights into machine performance, demand forecasting, and workflow optimizations.

Applications of AI and ML in Integrated Systems

Predictive Maintenance: By analyzing historical data from ERP systems, AI algorithms can predict when machinery will likely fail, allowing for proactive maintenance scheduling.

Optimized Scheduling: Machine learning algorithms can analyze past scheduling performance, helping PlanetTogether recommend scheduling adjustments to maximize efficiency.

Inventory Forecasting: Integrating AI with ERP data enables more accurate forecasting, reducing stockouts and surplus inventory.

Quality Control: AI-based algorithms can detect anomalies in production processes, flagging potential quality issues before they reach the customer.

Implementing IoT for Real-Time Data Integration

IoT devices collect real-time data from manufacturing equipment, which can then be integrated with ERP systems and scheduling software like PlanetTogether. This integration enables Manufacturing IT Managers to monitor operational performance continuously, gaining insights into machine efficiency, energy consumption, and potential bottlenecks.

IoT Use Cases in Manufacturing

Remote Monitoring: With IoT sensors, IT managers can monitor machine conditions remotely, which is invaluable for multisite operations.

Dynamic Scheduling: IoT devices feed real-time data into PlanetTogether, allowing the APS to adjust schedules instantly based on current machine availability and performance.

Enhanced Inventory Tracking: Integrating IoT devices with ERP systems provides accurate, real-time inventory data, ensuring materials are available when needed.

Environmental Monitoring: IoT can help monitor factory conditions, such as temperature and humidity, which are critical for processes sensitive to environmental factors.

The Role of Cloud Computing in Future-Proofing Infrastructure

Cloud computing offers flexibility, scalability, and accessibility, making it a valuable component of an emerging technology strategy. For Manufacturing IT Managers, migrating ERP systems and PlanetTogether’s APS to the cloud can create an adaptable infrastructure ready to accommodate future technology advancements.

Advantages of Cloud-Based Solutions

Scalability: Cloud platforms allow for easy expansion, accommodating growth without requiring new hardware or software investments.

Cost Savings: By reducing the need for on-site hardware and maintenance, cloud computing can decrease infrastructure costs.

Disaster Recovery: Cloud solutions often come with built-in redundancy, ensuring data recovery in case of system failures.

Collaborative Workflows: Cloud-based integration allows access from any location, enabling collaboration between teams and remote monitoring of production data.

Implementation Strategy

Evaluate Cloud Providers: Select a provider compatible with both your ERP system and APS, focusing on compliance with data protection standards.

Hybrid Cloud Solutions: For organizations cautious about moving everything to the cloud, hybrid solutions offer a way to combine on-premises and cloud capabilities.

Security Protocols: Partner with the provider to ensure compliance with security regulations and implement robust monitoring.

Key Considerations for a Strategic Implementation

When adopting these technologies and integrating them with systems like PlanetTogether and your ERP, a well-structured implementation strategy is essential.

Set Clear Goals: Define specific outcomes, such as reduced downtime, improved throughput, or cost savings.

Pilot Programs: Conduct pilot programs for each technology, assessing its impact and resolving any integration issues.

Monitor and Optimize: Continuously monitor system performance and make adjustments as necessary.

Engage Stakeholders: Include input from operations, maintenance, and production teams to ensure buy-in and that the technology supports their needs.

Adopting emerging technologies in industrial manufacturing offers significant potential to enhance productivity, reduce costs, and drive continuous improvement. For Manufacturing IT Managers, the integration of PlanetTogether with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva allows for synchronized workflows, real-time data accessibility, and predictive analytics.

While the road to full integration may have its challenges, strategic planning, a focus on cybersecurity, and employee training will help smooth the transition. By leveraging the power of AI, IoT, cloud computing, and advanced scheduling systems, Manufacturing IT Managers can create a dynamic, future-ready environment that keeps their facility competitive and responsive to market demands.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Industrial Manufacturing, PlanetTogether Software, Integrating PlanetTogether, Enhanced Visibility, Optimized Scheduling, Improved Predictive Maintenance, Agile and Responsive Manufacturing Process., Dynamic Inventory Forecasting, Improved Decision-Making Agility, Streamline Workflows, Advanced Inventory Forecasting, Remote Monitoring, AI and ML, IoT and IIoT

LEAVE A COMMENT