Adopting Emerging Technologies

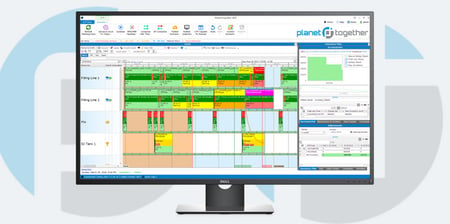

As a Manufacturing IT Manager in the chemical manufacturing sector, you face the dual challenges of operational efficiency and technological adaptation. Emerging technologies, from IoT and AI to digital twins and cloud integration, offer powerful tools to streamline operations, optimize resources, and improve overall productivity. However, to truly leverage these tools, seamless integration with existing systems, like PlanetTogether and ERP platforms such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, is crucial.

This blog explores the role of emerging technologies in chemical manufacturing, the benefits they bring to IT infrastructure, and practical strategies for integration to make your operation agile, scalable, and future-ready.

The Role of Emerging Technologies in Chemical Manufacturing

The chemical manufacturing sector operates within a high-stakes environment where downtime, waste, and inefficiencies can significantly impact profitability. With regulatory compliance, supply chain variability, and complex product mixes to manage, emerging technologies have the potential to transform operational resilience.

IoT and Smart Sensors

IoT in chemical manufacturing enables real-time monitoring of equipment, process flows, and inventory levels. Smart sensors can continuously track variables like temperature, pressure, and humidity, helping to detect anomalies early and avoid costly downtime.

Artificial Intelligence and Machine Learning

AI and ML can analyze vast amounts of operational data to optimize production schedules, reduce waste, and improve quality. For example, predictive maintenance algorithms can predict equipment failures before they happen, minimizing disruptions and reducing maintenance costs.

Digital Twins

By creating a digital representation of physical assets, digital twins allow for advanced simulations and predictive insights. This can be crucial in managing complex chemical processes, enabling operators to test and optimize processes virtually before implementing them in the physical environment.

Cloud Computing and Edge Computing

Cloud computing offers scalability and flexibility for data management, allowing for faster access to data across the enterprise. Edge computing brings computational power closer to the production floor, reducing latency and enabling faster decision-making.

Benefits of Integrating PlanetTogether with ERP Systems

Effective integration between PlanetTogether and ERP systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva is essential for chemical manufacturing IT managers to fully harness the benefits of emerging technologies. Here’s why:

End-to-End Visibility

By linking PlanetTogether with ERP systems, manufacturing IT managers can achieve end-to-end visibility across production, inventory, and supply chain. This integration allows for real-time data synchronization, giving teams accurate insights into production schedules, material availability, and delivery timelines.

Streamlined Production Planning and Scheduling

PlanetTogether’s advanced scheduling capabilities combined with an ERP’s powerful data handling can optimize production schedules. For example, integrating PlanetTogether with SAP’s data on raw materials availability allows the system to automatically adjust schedules based on real-time changes in supply levels.

Enhanced Data Accuracy and Consistency

When PlanetTogether integrates with ERP systems, it eliminates the need for manual data entry, reducing errors and ensuring consistency across departments. This accuracy is crucial for chemical manufacturing, where minor deviations can lead to safety risks and regulatory issues.

Improved Resource Utilization

Integrated systems allow for optimized resource utilization by automatically adjusting production plans based on equipment availability, labor, and material resources. This is particularly valuable in chemical manufacturing, where batch production and resource scheduling are critical.

Key Steps for Adopting Emerging Technologies and Integrating with PlanetTogether

1. Assess Current IT and Operational Infrastructure

Start by assessing your current IT landscape to determine compatibility with emerging technologies and ERP integration requirements. This includes reviewing network architecture, data storage capacity, and cybersecurity measures. An understanding of your infrastructure will help identify potential challenges and streamline the integration process.

2. Identify Technology Priorities Based on Business Goals

Prioritizing which emerging technologies align best with your facility's goals is essential. If predictive maintenance is a top priority, investing in IoT and AI-enabled predictive analytics might be your first step. For real-time decision-making, edge computing may provide the necessary agility.

3. Leverage Cloud and Edge Computing

Cloud and edge computing can work together to balance data processing needs. For example, integrating PlanetTogether with Microsoft Azure’s cloud infrastructure can store and process large data volumes, while edge devices handle real-time data near the source.

4. Develop a Data Integration Strategy

A solid data integration strategy is vital to successful integration. Ensure data flows seamlessly between PlanetTogether and ERP platforms like SAP or Oracle, leveraging APIs, middleware, or custom connectors if necessary. Standardizing data formats and protocols is essential to maintain data integrity and compatibility.

5. Implement Robust Cybersecurity Protocols

With the introduction of IoT devices and cloud systems, cybersecurity becomes more complex. Employ multi-layered security measures, including encryption, secure access controls, and regular system audits. ERP systems like Oracle and SAP have built-in security features that can complement PlanetTogether’s security protocols.

6. Pilot Testing and User Training

Before a full-scale rollout, conduct pilot tests to ensure that PlanetTogether and ERP integration meet operational requirements. This step will help identify any issues that could affect production and allows for adjustments. Additionally, invest in user training to ensure that the workforce understands the new processes and tools.

Maximizing ROI on Emerging Technologies

Adopting new technology is a substantial investment. To maximize ROI, it’s essential to focus on measurable outcomes that can improve operational efficiency and reduce costs.

Enhance Production Efficiency and Flexibility

Integrating PlanetTogether with ERP systems enables more flexible production scheduling, helping reduce downtime and idle equipment. For example, Kinaxis can provide real-time demand insights, allowing PlanetTogether to adjust production schedules proactively.

Reduce Waste and Optimize Inventory Management

With digital twins and AI-powered analytics, it’s possible to simulate production scenarios and optimize resources. By integrating PlanetTogether with inventory data in SAP or Oracle, IT managers can ensure that raw materials are available when needed without excessive stockpiling.

Improve Compliance and Quality Control

The chemical industry has stringent compliance requirements. With IoT sensors, you can maintain quality and safety by monitoring conditions and identifying deviations in real-time. Through integration, PlanetTogether can alert ERP systems like Aveva or Microsoft Dynamics of compliance risks, ensuring timely intervention.

Increase Predictive Maintenance Capabilities

Predictive maintenance with AI and IoT reduces unplanned downtime by alerting teams of potential failures before they occur. Integrating PlanetTogether’s scheduling with predictive maintenance insights from SAP or Oracle can ensure that equipment maintenance is scheduled with minimal impact on production.

The journey to adopting emerging technologies in chemical manufacturing requires a well-planned approach to ensure integration with existing systems, like PlanetTogether and ERP platforms such as SAP, Oracle, Microsoft, Kinaxis, and Aveva. By following best practices in integration, prioritizing technologies based on facility needs, and focusing on measurable ROI, manufacturing IT managers can help create a more efficient, resilient, and sustainable operation.

Staying proactive in adopting and integrating these technologies will not only enhance operational efficiency but also position your facility at the forefront of innovation in the chemical manufacturing industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.