Adopting Agile Purchasing Strategies in Chemical Manufacturing: Navigating Volatility with Integrated APS and ERP Solutions

In today’s dynamic global landscape, chemical manufacturers face mounting pressures from geopolitical shifts, fluctuating raw material prices, regulatory constraints, and sustainability mandates. For Purchasing Managers, maintaining cost efficiency, supplier reliability, and compliance is more challenging than ever. As traditional procurement models fall short, adopting agile strategies is becoming essential to survive and thrive.

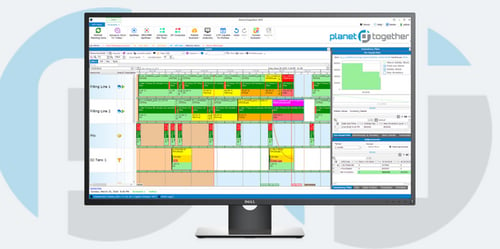

Agility in procurement means more than rapid responsiveness—it involves predictive planning, cross-functional collaboration, and data-driven decision-making. For chemical manufacturers, this is where the integration of Advanced Planning and Scheduling (APS) systems like PlanetTogether with enterprise platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva becomes a critical enabler.

The Challenges of Traditional Procurement in Chemical Manufacturing

Chemical manufacturing operates under unique procurement pressures:

Volatile raw material prices due to supply chain disruptions or petrochemical dependencies.

Complex supplier networks with long lead times and strict quality requirements.

Regulatory compliance regarding hazardous materials, sustainability reporting, and global trade.

Inflexible planning models that lack the real-time responsiveness required for today’s fast-changing conditions.

In this environment, relying solely on static purchasing schedules or disconnected systems can lead to excessive inventory, supplier dissatisfaction, and missed production targets. Agility isn’t just a buzzword—it’s a strategic necessity.

What Does Agile Purchasing Look Like?

Agile purchasing isn’t about frequent changes or reactive buying—it’s a structured yet adaptable approach that enables:

Real-time procurement visibility: Access to live demand forecasts, inventory levels, and supplier status.

Scenario-based planning: The ability to simulate different supplier lead times, costs, or geopolitical risks.

Collaborative workflows: Integrated systems that allow procurement, production, and supply chain teams to co-plan effectively.

Rapid response capabilities: Systems that dynamically adjust procurement schedules in response to market shifts or production changes.

These capabilities require a shift from legacy ERP-only models to integrated ecosystems, where APS platforms like PlanetTogether bridge operational silos and enable agile execution.

Integrating PlanetTogether with ERP Platforms: A Game-Changer for Purchasing Managers

Why Integration Matters

PlanetTogether APS is designed to augment ERP systems by offering advanced planning, real-time scheduling, and optimization features. For Purchasing Managers in chemical manufacturing, integrating PlanetTogether with SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva can offer:

Demand-driven procurement planning: Align raw material purchases precisely with production schedules.

Supplier performance analytics: Track on-time delivery, cost fluctuations, and risk levels.

Procurement flexibility: Make quick adjustments to purchasing plans without disrupting downstream processes.

Improved cross-departmental coordination: Real-time data sharing between procurement, production, and supply chain.

Key Agile Purchasing Strategies Enabled by Integration

Just-in-Time and Just-in-Sequence Procurement

Through tight alignment with production schedules via PlanetTogether, raw material orders can be timed precisely. This minimizes inventory and storage costs—critical for chemicals with limited shelf life or safety concerns.

Multi-Sourcing and Supplier Flexibility

With PlanetTogether’s scenario modeling, purchasing managers can assess the impact of switching suppliers based on cost, lead time, and reliability. When integrated with platforms like Kinaxis or Oracle, supplier scorecards and historical performance feed directly into procurement decisions.

Dynamic Safety Stock Recalculation

Agile systems allow for dynamic buffer levels based on real-time risk assessment. Integration with Microsoft Dynamics or Aveva ensures inventory thresholds automatically adjust in response to volatility.

Responsive Budget Management

Budgeting becomes proactive rather than reactive. With live data feeds from APS and ERP platforms, chemical manufacturers can flag deviations early, analyze cost trends, and adjust procurement plans in real time.

Collaborative Supplier Relationship Management (SRM)

Integrated platforms allow suppliers to access demand forecasts and planning schedules. This fosters transparency, strengthens partnerships, and ensures on-time delivery—even in turbulent conditions.

Organizational Benefits of Agile Procurement

Adopting agile procurement strategies through integrated APS and ERP platforms brings numerous tangible benefits:

Reduced raw material costs through better timing and negotiation.

Shorter lead times and improved responsiveness to market changes.

Lower inventory carrying costs and reduced waste.

Enhanced supplier collaboration and trust.

Greater resilience against geopolitical disruptions and raw material shortages.

For chemical manufacturers managing global operations, these improvements can translate into a significant competitive edge.

Overcoming Implementation Hurdles

While the benefits are clear, transitioning to an agile procurement model requires thoughtful implementation. Common challenges include:

Resistance to change: Procurement teams may be accustomed to static ordering models.

Data silos: Disconnected systems hinder the flow of information between procurement and production.

Integration complexity: Connecting PlanetTogether with SAP, Oracle, or other platforms requires collaboration between IT and operations.

To succeed, organizations should adopt a phased approach:

Start with pilot projects in high-impact areas such as key raw materials.

Engage cross-functional teams early in the process to ensure buy-in.

Leverage vendor expertise—PlanetTogether and ERP providers often offer tailored integration blueprints.

Invest in training to build internal capabilities for managing agile workflows.

As market uncertainty becomes the norm, Purchasing Managers in chemical manufacturing must lead the shift toward agility. By integrating advanced planning tools like PlanetTogether with ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, procurement teams can respond faster, plan smarter, and collaborate better.

Agile procurement isn't just about doing things faster—it's about doing them better, with intelligence, insight, and foresight. In an industry where a single supply chain disruption can halt production, the time to invest in agility is now.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Collaborative Workflows, Chemical Manufacturing, Scenario-Based Planning, Real-time procurement visibility, Procurement Flexibility, Rapid Response Capabilities

LEAVE A COMMENT