Adaptive Scheduling with Predictive Analytics and PlanetTogether: Transforming Supply Chain Efficiency in Chemical Manufacturing

Supply chain managers face a multitude of challenges, from fluctuating raw material availability to sudden shifts in demand. Adapting to these challenges requires not just robust systems but also innovative strategies that leverage the latest technologies. This is where adaptive scheduling powered by predictive analytics, integrated with advanced solutions like PlanetTogether and enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, becomes a game-changer.

The Complexity of Chemical Supply Chains

Chemical manufacturing supply chains are among the most complex, involving volatile raw materials, stringent safety regulations, and precise production requirements. Delays or inefficiencies at any stage can result in significant financial and operational setbacks. Traditional static scheduling approaches often fail to address the intricacies of chemical manufacturing, leading to:

Inefficient resource utilization: Underutilized or overburdened equipment and labor.

Extended lead times: Delays in production cycles due to unforeseen bottlenecks.

Inaccurate demand forecasting: Challenges in aligning production with market needs.

Adaptive scheduling, augmented with predictive analytics and integrated with systems like PlanetTogether, offers a forward-looking solution to these challenges.

What is Adaptive Scheduling?

Adaptive scheduling is a dynamic approach that continuously adjusts production schedules based on real-time data, predictive insights, and evolving operational parameters. Unlike static schedules that are fixed at the outset, adaptive scheduling enables flexibility to respond to:

Changes in demand patterns.

Equipment breakdowns or maintenance requirements.

Supply chain disruptions or raw material shortages.

By integrating adaptive scheduling with predictive analytics, chemical manufacturers gain the ability to anticipate issues before they occur, optimize resource allocation, and align production with market demands seamlessly.

The Role of Predictive Analytics

Predictive analytics leverages historical data, machine learning, and statistical algorithms to forecast future outcomes. In the context of supply chain management and production scheduling, predictive analytics can:

Enhance Demand Forecasting: Provide accurate predictions of market demand based on trends, seasonality, and external factors.

Optimize Maintenance Scheduling: Predict equipment failures and recommend preventive measures to minimize downtime.

Streamline Inventory Management: Ensure the right raw materials are available at the right time, reducing stockouts and excess inventory.

When paired with adaptive scheduling, predictive analytics transforms these forecasts into actionable insights, allowing supply chain managers to make proactive decisions.

![]()

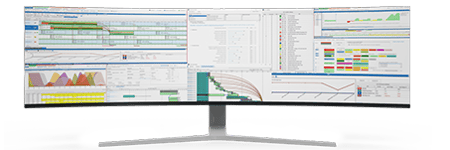

PlanetTogether: The Hub of Integration

PlanetTogether is a robust advanced planning and scheduling (APS) solution designed to optimize production processes and enhance supply chain efficiency. Its ability to integrate seamlessly with enterprise systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva creates a unified ecosystem where data flows seamlessly across all levels of the supply chain.

Key Features of PlanetTogether in Adaptive Scheduling:

Real-Time Visibility

PlanetTogether provides a centralized dashboard that visualizes production schedules, resource allocation, and operational bottlenecks in real time.

Scenario Planning

Enables supply chain managers to simulate "what-if" scenarios, helping them evaluate the impact of potential disruptions and choose the best course of action.

Automated Rescheduling

Automatically adjusts schedules based on real-time changes, ensuring minimal disruption to production timelines.

Collaboration Across Systems

Integration with enterprise systems ensures data consistency and enhances collaboration among departments.

Integration with SAP, Oracle, Microsoft, Kinaxis, and Aveva

The true power of PlanetTogether is unlocked when it integrates with enterprise resource planning (ERP) and supply chain management (SCM) systems. Here’s how these integrations amplify the benefits of adaptive scheduling:

SAP Integration

Enhanced Data Accuracy: Synchronizes production schedules with SAP’s material requirements planning (MRP) data.

Streamlined Workflows: Facilitates smooth transitions from production planning to execution.

Improved Compliance: Ensures adherence to safety and regulatory standards through integrated tracking.

Oracle Integration

Robust Analytics: Combines Oracle’s advanced analytics with PlanetTogether’s scheduling insights for data-driven decision-making.

Unified Operations: Creates a cohesive link between supply chain operations and shop-floor activities.

Microsoft Dynamics Integration

Seamless Collaboration: Enhances communication across departments using Microsoft’s familiar interfaces.

Real-Time Updates: Ensures production data is updated in Dynamics for accurate reporting and forecasting.

Kinaxis Integration

Agile Planning: Aligns Kinaxis’ rapid-response planning capabilities with PlanetTogether’s adaptive scheduling.

Improved Resilience: Anticipates and mitigates supply chain risks effectively.

Aveva Integration

Digital Twins: Utilizes Aveva’s digital twin technology to simulate and optimize production scenarios.

Enhanced Predictive Maintenance: Integrates operational data from Aveva with scheduling insights for proactive equipment management.

Benefits of Adaptive Scheduling with PlanetTogether

By integrating PlanetTogether and predictive analytics into the chemical manufacturing supply chain, supply chain managers can unlock:

Increased Efficiency

Real-time scheduling and predictive insights ensure optimal utilization of resources, reducing waste and boosting productivity.

Greater Agility

The ability to adapt to disruptions, whether from raw material shortages or market volatility, ensures a resilient supply chain.

Enhanced Customer Satisfaction

Faster response times and improved on-time delivery rates build trust and loyalty among customers.

Cost Savings

By optimizing inventory, reducing downtime, and improving resource allocation, adaptive scheduling delivers significant cost reductions.

The chemical manufacturing industry is at a crossroads, where traditional methods must evolve to meet the demands of a fast-paced, technology-driven world. Adaptive scheduling powered by predictive analytics and integrated with advanced systems like PlanetTogether and leading ERP platforms offers a clear path forward.

For supply chain managers, the adoption of these technologies isn’t just a strategic advantage—it’s a imperative. By embracing adaptive scheduling, chemical manufacturers can achieve unparalleled efficiency, agility, and resilience in their supply chains, positioning themselves for success in an ever-changing market.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Demand-Driven Scheduling, Enhanced Customer Satisfaction, Costs Savings, Streamline Inventory Management, Chemical Manufacturing, Enhance Demand Forecasting, Proactive Maintenance, Optimize Maintenance Scheduling

LEAVE A COMMENT