Achieving Sustainability Packaging

In the increasingly eco-conscious world, sustainability has become a paramount concern for businesses across all sectors. Nowhere is this more evident than in the packaging industry. As an Operations Director in a packaging manufacturing facility, you play a crucial role in driving sustainability initiatives while maintaining operational efficiency.

In this blog, we'll look into the realm of sustainable packaging solutions, exploring innovative approaches, technologies, and integrations that can revolutionize your operations.

Understanding Sustainable Packaging

Sustainable packaging refers to the use of materials and processes that minimize environmental impact throughout a product's lifecycle, from production to disposal. This encompasses factors such as material sourcing, manufacturing processes, transportation efficiency, and end-of-life disposal.

The Importance of Sustainable Packaging

Environmental Impact: Traditional packaging often contributes to pollution, deforestation, and resource depletion. Sustainable packaging aims to mitigate these impacts by reducing waste, utilizing renewable materials, and adopting eco-friendly practices.

Consumer Preference: Today's consumers are increasingly eco-conscious, seeking products packaged in environmentally friendly materials. Embracing sustainable packaging not only aligns with consumer values but also enhances brand reputation and loyalty.

Regulatory Compliance: Governments worldwide are implementing stricter regulations on packaging materials and waste management. By adopting sustainable practices, businesses can ensure compliance with evolving environmental standards and avoid penalties.

Challenges in Implementing Sustainable Packaging

While the benefits of sustainable packaging are clear, implementing it poses several challenges:

Cost Considerations: Sustainable materials and processes may incur higher initial costs compared to traditional alternatives, potentially impacting profit margins.

Supply Chain Complexity: Sourcing eco-friendly materials and ensuring their availability and quality within the supply chain can be challenging, particularly for global operations.

Operational Integration: Integrating sustainability initiatives with existing ERP, SCM, and MES systems can be complex, requiring seamless data exchange and process alignment.

Integrating Sustainability with Technology

To overcome these challenges and drive sustainable packaging solutions effectively, leveraging technology is paramount. Integrating advanced planning and execution systems, such as PlanetTogether, with ERP, SCM, and MES platforms can streamline operations and enhance sustainability efforts. Here's how:

Data Integration: Seamless integration between PlanetTogether and leading ERP systems like SAP, Oracle, or Microsoft enables real-time data exchange, facilitating accurate demand forecasting, inventory management, and resource optimization.

Supply Chain Visibility: By integrating with SCM systems, such as Kinaxis or Aveva, PlanetTogether provides end-to-end visibility into the supply chain, allowing proactive identification of sustainable sourcing opportunities and minimizing environmental impact.

Production Optimization: Leveraging MES integration, PlanetTogether optimizes production schedules based on sustainability criteria, such as minimizing waste, energy consumption, and carbon footprint.

Lifecycle Analysis: Integrating with lifecycle assessment tools enables comprehensive analysis of packaging materials' environmental impact, empowering informed decision-making and continuous improvement.

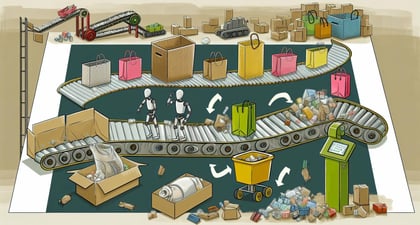

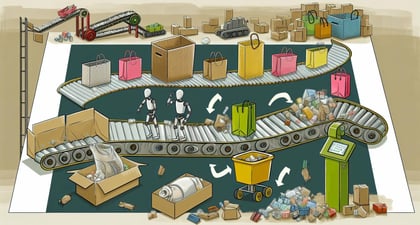

Innovative Sustainable Packaging Solutions

Biodegradable Materials: Embrace biodegradable alternatives to traditional plastics, such as compostable bioplastics derived from renewable sources like corn or sugarcane.

Recycled Content: Utilize recycled materials in packaging production, promoting circular economy principles and reducing reliance on virgin resources.

Lightweight Design: Optimize packaging design to minimize material usage while maintaining product protection, reducing transportation costs and environmental footprint.

Reusable Packaging: Implement reusable packaging solutions, such as crates or pallets, to minimize waste generation and enhance supply chain sustainability.

Smart Packaging: Explore IoT-enabled smart packaging solutions that provide real-time tracking, monitoring product freshness, and enhancing consumer engagement while reducing waste.

Measuring and Monitoring Sustainability Performance

To effectively manage sustainable packaging initiatives, it's crucial to establish key performance indicators (KPIs) and robust monitoring mechanisms. Track metrics such as:

Material Efficiency: Measure the percentage of recycled or renewable materials used in packaging production compared to virgin materials.

Waste Reduction: Monitor waste generation throughout the packaging lifecycle and implement strategies to minimize it.

Carbon Footprint: Quantify the greenhouse gas emissions associated with packaging production, transportation, and disposal, aiming for continuous reduction over time.

Customer Satisfaction: Solicit feedback from customers regarding packaging preferences and perceptions of sustainability efforts.

As an Operations Director in a packaging manufacturing facility, embracing sustainable packaging solutions is not just a choice but a necessity in today's environmentally conscious landscape. By leveraging advanced technologies like PlanetTogether and integrating them with ERP, SCM, and MES systems, you can optimize operations while minimizing environmental impact. From biodegradable materials to smart packaging solutions, the possibilities for sustainable innovation are endless.

Remember, sustainability isn't just a trend; it's a responsibility we owe to future generations and the planet we call home. Embrace it, innovate, and together, let's build a more sustainable tomorrow.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the packaging industry.