Scalable and Cost-Effective Production Management

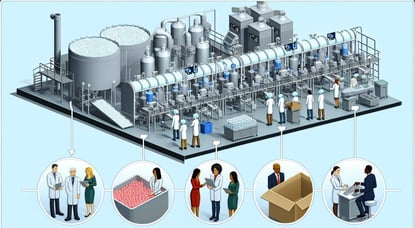

In the demanding landscape of medical manufacturing, the role of purchasing managers is pivotal. As you navigate the complexities of procurement, you're tasked with ensuring the smooth flow of materials, optimizing inventory levels, and ultimately, driving cost efficiencies without compromising on quality or compliance. In such a dynamic environment, the need for scalable and cost-effective production management solutions has never been more pronounced.

Fortunately, technological advancements offer a beacon of hope for procurement professionals striving to meet these challenges head-on. Among the myriad of tools available, integrating advanced planning and scheduling (APS) systems like PlanetTogether with enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES) presents a compelling solution.

This blog aims to explore how such integration can revolutionize production management in medical manufacturing facilities, empowering purchasing managers to streamline operations, enhance visibility, and drive sustainable growth.

The Imperative of Integration

Medical manufacturing is characterized by stringent regulations, rapid innovation, and fluctuating demand patterns. In such an environment, siloed operations and disjointed systems can impede efficiency and hinder responsiveness. Integrating APS systems with existing ERP, SCM, and MES platforms emerges as a strategic imperative to overcome these challenges.

Enhanced Visibility: Integration fosters seamless data exchange across disparate systems, providing purchasing managers with real-time insights into inventory levels, production schedules, and demand forecasts. This heightened visibility enables proactive decision-making, minimizing stockouts, reducing excess inventory, and mitigating supply chain disruptions.

Optimized Production Planning: By harnessing the power of APS, purchasing managers can optimize production planning processes, aligning manufacturing capacity with demand forecasts and resource constraints. Advanced algorithms facilitate scenario analysis, enabling stakeholders to evaluate various production scenarios and identify the most cost-effective strategies.

Improved Efficiency: Integrated systems eliminate manual data entry and redundant processes, freeing up valuable time for purchasing managers to focus on strategic initiatives. By automating routine tasks such as order processing, material requisition, and scheduling, organizations can achieve significant productivity gains and operational efficiencies.

Agility and Responsiveness: In today's volatile marketplace, agility is paramount. Integrated systems empower purchasing managers to swiftly adapt to changing demand patterns, market dynamics, and regulatory requirements. By synchronizing production schedules with customer orders and supplier deliveries, organizations can enhance responsiveness and capitalize on emerging opportunities.

Unleashing the Power of Integration: PlanetTogether and ERP/SCM/MES Systems

At the heart of this transformative journey lies the integration between PlanetTogether—an industry-leading APS solution—and prominent ERP, SCM, and MES platforms such as SAP, Oracle, Microsoft, Kinaxis, and Aveva. Let's delve deeper into how this integration can unlock unparalleled value for medical manufacturing facilities:

Seamless Data Exchange: Integration bridges the gap between planning and execution, facilitating seamless data exchange between PlanetTogether and ERP/SCM/MES systems. Real-time synchronization ensures that production plans are aligned with inventory levels, resource availability, and customer demand, enabling organizations to optimize production schedules with precision.

Unified Planning Environment: By consolidating disparate planning processes into a unified environment, integration fosters collaboration and alignment across cross-functional teams. Purchasing managers can leverage a single source of truth to orchestrate end-to-end production workflows, from demand forecasting and material procurement to production scheduling and order fulfillment.

Dynamic Scenario Analysis: PlanetTogether's advanced algorithms empower purchasing managers to conduct dynamic scenario analysis, evaluating the impact of various constraints and contingencies on production performance. By simulating different scenarios and assessing key performance indicators (KPIs) such as lead times, inventory turns, and resource utilization, organizations can identify optimal strategies for maximizing efficiency and minimizing costs.

Predictive Analytics and AI: Leveraging the power of predictive analytics and artificial intelligence (AI), integrated systems enable predictive maintenance, demand forecasting, and supplier performance analysis. By harnessing historical data and machine learning algorithms, organizations can anticipate demand fluctuations, preempt equipment failures, and optimize procurement strategies, thereby enhancing operational resilience and competitiveness.

Compliance and Quality Management: In the highly regulated landscape of medical manufacturing, compliance and quality management are paramount. Integration facilitates traceability and visibility across the entire supply chain, enabling organizations to track raw materials, components, and finished products from source to destination. By enforcing rigorous quality control measures and documenting compliance with regulatory standards, organizations can safeguard patient safety and uphold their reputation for excellence.

Embracing the Future of Production Management

The quest for scalable and cost-effective production management in medical manufacturing necessitates a paradigm shift towards integration and innovation. By harnessing the synergies between advanced planning and scheduling systems like PlanetTogether and ERP/SCM/MES platforms, purchasing managers can unlock unprecedented efficiencies, agility, and competitiveness.

As you embark on this transformative journey, remember that success lies not only in adopting cutting-edge technologies but also in fostering a culture of collaboration, continuous improvement, and data-driven decision-making. By embracing the future of production management, medical manufacturing facilities can navigate the complexities of the modern marketplace with confidence and resilience, delivering value to patients, customers, and stakeholders alike.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT