In the landscape of pharmaceutical manufacturing, staying ahead requires a strategic approach to production scheduling. Operations Directors play a pivotal role in orchestrating the intricate dance of resources, timelines, and efficiency. One key methodology gaining prominence is Lean Production Scheduling, and an essential component of it is the implementation of Takt Time.

In this blog, we'll explore the significance of Takt Time and how integrating it with sophisticated software like PlanetTogether can revolutionize pharmaceutical manufacturing operations.

But first... What is Operational Excellence?

Operational Excellence (OpEx) is a business management philosophy and a set of practices that focus on continually improving an organization's operations to deliver high-quality products and services more efficiently and effectively. It involves the systematic and disciplined management of processes, people, and technology to drive sustained improvement and achieve superior business performance.

Understanding Takt Time

Takt Time, derived from the German word 'Takt,' meaning pulse or rhythm, is a lean manufacturing concept that establishes the heartbeat of production. It is the rate at which a product must be manufactured to meet customer demand while maintaining a smooth, continuous flow. Takt Time aligns production with customer needs, preventing overproduction and ensuring resources are utilized optimally.

Challenges in Pharmaceutical Manufacturing

Pharmaceutical manufacturing poses unique challenges such as stringent regulations, complex supply chains, and varying production volumes. Operations Directors are tasked with finding solutions that enhance efficiency while maintaining compliance. Takt Time, when applied judiciously, addresses these challenges, promoting a lean and agile production environment.

Integration with PlanetTogether

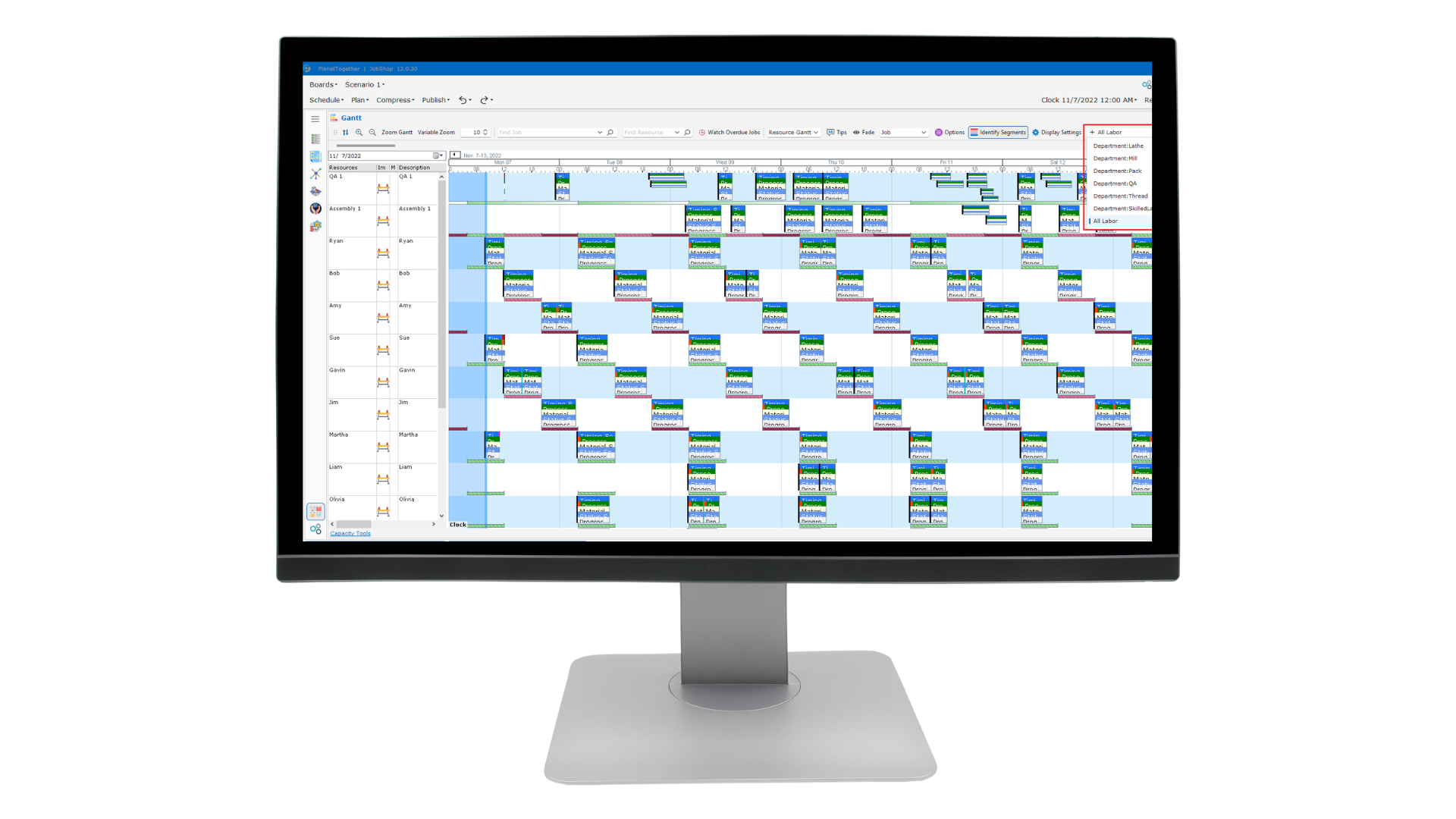

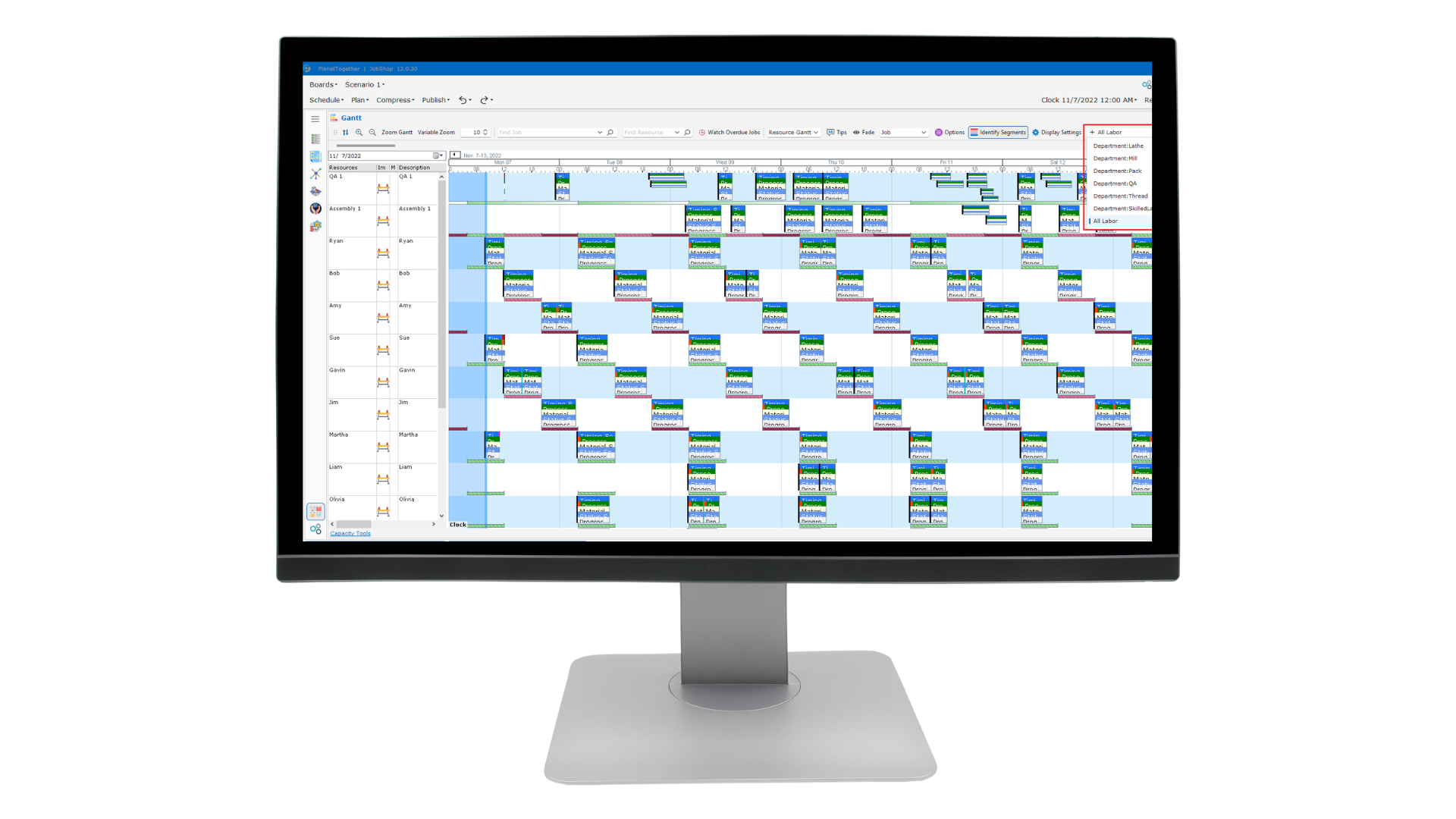

To harness the full potential of Takt Time, Operations Directors can leverage advanced production scheduling solutions like PlanetTogether. PlanetTogether is a robust tool that offers dynamic scheduling capabilities, allowing for real-time adjustments to production schedules based on demand fluctuations, resource availability, and other variables.

Integration with ERP Systems

For seamless implementation, integration with Enterprise Resource Planning (ERP) systems becomes crucial. Pharmaceutical manufacturing facilities often use ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva. Integrating PlanetTogether with these ERP systems streamlines data exchange, ensuring accurate and timely information flow between production scheduling and other critical business processes.

Benefits of Integration

Real-time Visibility

- Integration with ERP systems provides real-time visibility into inventory levels, demand forecasts, and resource availability.

- Operations Directors can make informed decisions based on up-to-date information, reducing the risk of disruptions.

Efficient Resource Allocation

- PlanetTogether's integration with ERP systems allows for efficient allocation of resources based on Takt Time requirements.

- Operations Directors can optimize workforce, equipment, and materials to align with production needs.

Improved Compliance

- Compliance in the pharmaceutical industry is non-negotiable. Integration ensures that production schedules adhere to regulatory requirements.

- Accurate documentation and reporting become easier, aiding in audits and inspections.

Enhanced Collaboration

- Integration fosters collaboration between different departments, breaking down silos and promoting a holistic approach to production.

- Improved communication between production scheduling and other functions leads to better decision-making.

Adaptability to Change

- The pharmaceutical landscape is dynamic, with market demands and regulations constantly evolving. Integrated systems enable quick adaptation to changes in production requirements.

In the pursuit of operational excellence, Operations Directors in pharmaceutical manufacturing must embrace innovative solutions. Implementing Takt Time in Lean Production Scheduling, coupled with the integration of advanced tools like PlanetTogether and ERP systems, offers a transformative approach.

The result is a lean, agile, and compliant production environment that not only meets customer demands but also positions the facility for sustained success in an ever-evolving industry.