Achieving End-to-End Visibility in Complex Manufacturing Networks

In medical manufacturing, precision, accuracy, and efficiency are paramount. The production scheduler plays a pivotal role in ensuring that products are manufactured and delivered on time while maintaining the highest quality standards. However, as manufacturing networks grow more complex, the need for end-to-end visibility becomes increasingly crucial.

In this blog, we will explore the challenges faced by production schedulers in medical manufacturing facilities and how integrating advanced planning and scheduling solutions like PlanetTogether with ERP, SCM, and MES systems can revolutionize the way you manage your operations.

The Complexity of Medical Manufacturing

Medical manufacturing is not for the faint-hearted. The industry demands meticulous attention to detail, strict compliance with regulations, and the ability to adapt to ever-evolving market demands. As a production scheduler, you are tasked with orchestrating a highly complex web of processes, materials, and resources. This complexity often results in several challenges:

Demand Variability: Fluctuating market demands, seasonal trends, and unforeseen events can wreak havoc on production schedules.

Resource Constraints: Limited availability of specialized equipment, skilled labor, and raw materials can hinder your ability to meet production targets.

Regulatory Compliance: Strict regulations and quality standards are non-negotiable in the medical manufacturing industry. Ensuring compliance adds another layer of complexity to scheduling.

Global Supply Chains: Many medical manufacturing facilities rely on a global supply chain, making them vulnerable to disruptions, such as geopolitical issues, natural disasters, or supplier delays.

Data Overload: Managing data from various sources, including ERP, SCM, MES, and production equipment, can be overwhelming and lead to information silos.

The Quest for End-to-End Visibility

To overcome these challenges, production schedulers need to enhance their visibility across the entire manufacturing network. End-to-end visibility provides real-time insights into every facet of the operation, enabling you to make informed decisions and respond quickly to changing circumstances.

The Role of Advanced Planning and Scheduling (APS) Tools

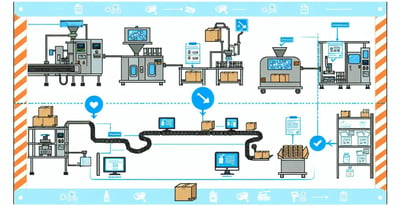

One of the most effective ways to achieve end-to-end visibility is by integrating advanced planning and scheduling (APS) solutions like PlanetTogether with your existing ERP, SCM, and MES systems. These tools act as a bridge, connecting disparate systems and providing a holistic view of your manufacturing processes.

![]()

The Power of PlanetTogether

PlanetTogether is a leading APS software that specializes in complex manufacturing environments. Its capabilities go beyond traditional scheduling and offer a comprehensive solution for production schedulers in medical manufacturing facilities.

Advanced Scheduling Algorithms: PlanetTogether employs advanced algorithms to optimize production schedules, taking into account complex constraints and objectives.

Real-time Data Integration: PlanetTogether seamlessly integrates with various ERP, SCM, and MES systems, ensuring that your scheduling decisions are based on the most up-to-date information.

Scenario Planning: With PlanetTogether, you can create and analyze multiple production scenarios to determine the best course of action in response to changing conditions.

Resource Management: The software helps you allocate resources efficiently, ensuring that critical assets and personnel are utilized optimally.

Customization: PlanetTogether is highly customizable, allowing you to tailor it to your specific needs and workflows.

Integration with ERP, SCM, and MES Systems

The true power of end-to-end visibility is realized when you integrate PlanetTogether with your existing systems. Let's explore the benefits of such integration:

ERP Integration

Enterprise Resource Planning (ERP) systems are the backbone of many medical manufacturing facilities. Integrating PlanetTogether with your ERP system, whether it's SAP, Oracle, Microsoft, or another, brings several advantages:

Data Consistency: Ensure that scheduling decisions are based on the same data used across the organization.

Streamlined Operations: Automate data exchange between scheduling and ERP systems, reducing manual input and minimizing errors.

Order Visibility: Provide real-time order status updates to sales, customer service, and management teams.

SCM Integration

Supply Chain Management (SCM) systems are essential for managing the flow of materials and components. Integrating PlanetTogether with your SCM system enhances:

Inventory Management: Maintain optimal inventory levels by aligning production schedules with demand forecasts.

Supplier Collaboration: Facilitate communication with suppliers by sharing production schedules and demand forecasts.

Supply Chain Optimization: Optimize your supply chain by synchronizing production schedules with supplier deliveries and transportation logistics.

MES Integration

Manufacturing Execution Systems (MES) play a critical role in monitoring and controlling the shop floor. Integrating PlanetTogether with MES systems offers:

Real-time Visibility: Gain real-time insights into shop floor operations, including machine status and job progress.

Quality Control: Ensure that quality standards are met by integrating MES data with scheduling decisions.

Traceability: Track materials and components from receipt to finished product, enhancing traceability for regulatory compliance.

Achieving True End-to-End Visibility

The integration of PlanetTogether with your ERP, SCM, and MES systems is not just about connecting software; it's about creating a seamless flow of data and information across your manufacturing network. Here's how you can achieve true end-to-end visibility:

Data Standardization

Ensure that data from all systems is standardized and compatible. This includes standardizing product codes, unit of measurement, and data formats. Standardization enables smooth data exchange between systems.

Real-time Data Sync

Implement real-time data synchronization between PlanetTogether and your ERP, SCM, and MES systems. This ensures that everyone is working with the most current information, reducing the risk of errors and miscommunication.

Cross-functional Collaboration

Encourage cross-functional collaboration between production scheduling, procurement, quality control, and other departments. End-to-end visibility should not be limited to one team but should benefit the entire organization.

Continuous Monitoring and Optimization

End-to-end visibility is not a one-time achievement but an ongoing process. Continuously monitor and optimize your manufacturing processes based on the insights provided by integrated systems.

In the complex world of medical manufacturing, end-to-end visibility is not a luxury; it's a necessity. As a production scheduler, your ability to meet production targets, ensure quality, and adapt to changing market conditions hinges on your capacity to see and respond to the entire manufacturing network.

Integrating advanced planning and scheduling solutions like PlanetTogether with ERP, SCM, and MES systems is the key to achieving this visibility. It empowers you with real-time data, optimization capabilities, and the agility to respond to market dynamics swiftly.

As the medical manufacturing landscape continues to evolve, staying ahead of the curve requires embracing technologies and practices that enable end-to-end visibility. Make the investment in integration today, and secure your position at the forefront of the industry's future. Your role as a production scheduler will be more critical than ever in shaping the success of your facility and ensuring the well-being of patients who rely on your products.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the medical industry.

Topics: Quality Control, PlanetTogether Software, Data Consistency, Integrating PlanetTogether, Real-Time Data Integration, Inventory and Supply Chain Optimization, Dynamic Scenario Planning, Resource Management, End-to-End Traceability, Medical Manufacturing

LEAVE A COMMENT